At their core, chemical-resistant safety shoes provide a critical barrier between your feet and hazardous substances. They achieve this by using specialized, non-porous materials for the uppers and soles, such as specific types of rubber or neoprene. This construction is designed to prevent corrosive liquids from making contact with your skin, thereby protecting you from chemical burns and other long-term health issues.

The most critical takeaway is that "chemical resistance" is not a universal feature. True protection depends on matching the shoe's specific material composition to the exact chemicals present in your work environment, as general-purpose safety features are not a substitute.

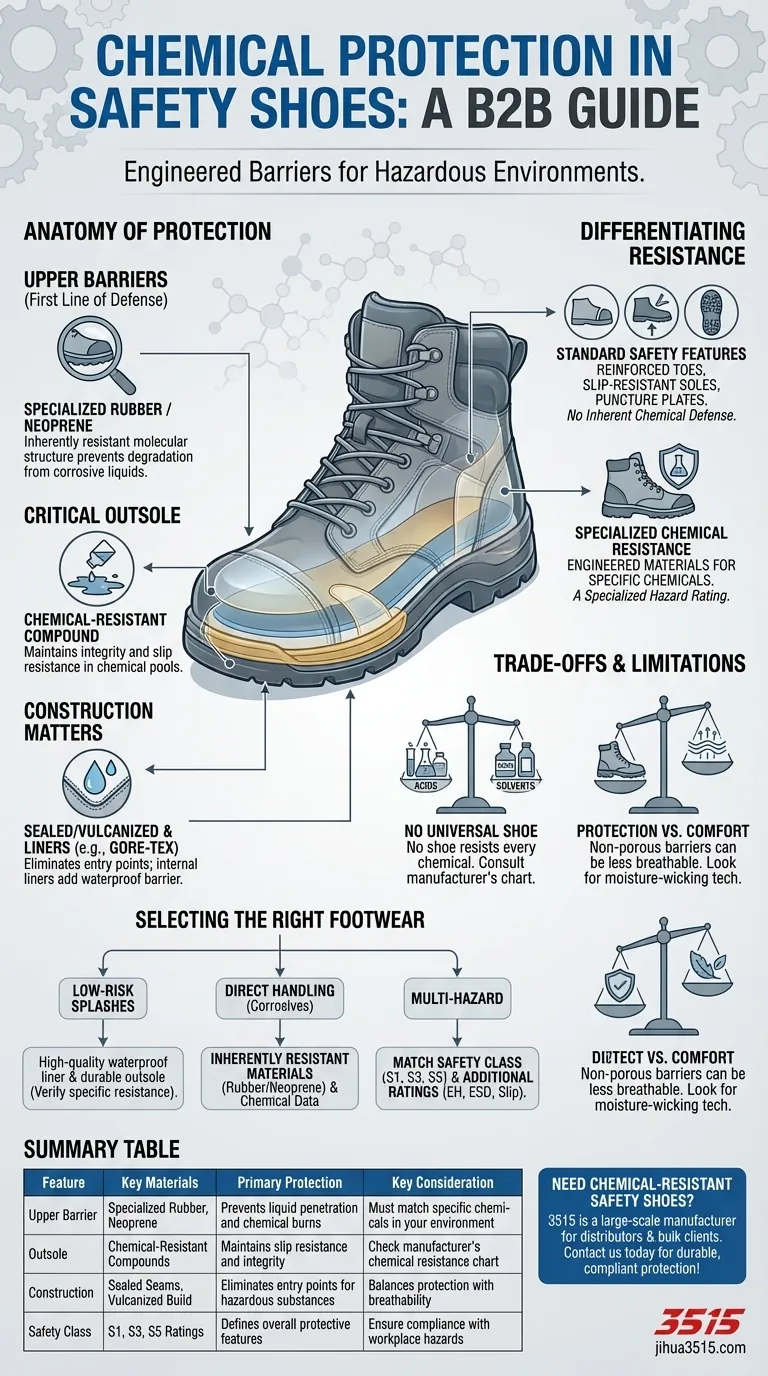

The Anatomy of Chemical Protection

True chemical resistance is engineered into the very fabric of the footwear. It is a deliberate design choice that goes far beyond a simple waterproof coating.

The Role of Barrier Materials

The first line of defense is the material used for the shoe's upper. Materials like specialized rubber and neoprene are chosen because their molecular structure is inherently resistant to degradation from corrosive or hazardous liquids.

The Critical Importance of the Outsole

The outsole is the part of the shoe in constant contact with the ground, where chemical spills often pool. A chemical-resistant outsole is made from a compound that will not break down, swell, or lose its integrity when exposed to specific chemicals, ensuring both protection and slip resistance are maintained.

Seams, Liners, and Overall Construction

Protection can be compromised at the seams. High-quality chemical-resistant footwear often uses sealed or vulcanized construction to eliminate pathways for liquids to enter. Internal liners, such as those made from GORE-TEX, can provide an additional waterproof barrier, but they must be paired with a chemically resistant outer to be effective against harsh substances.

Differentiating Chemical Resistance from General Safety

A safety shoe can be loaded with features, but it's vital to distinguish between general protection and the specific feature you need.

Standard Safety Features

Most safety shoes include a baseline of protection. This typically includes reinforced toe caps (steel or composite) for impact, slip-resistant soles for traction, and often puncture-resistant plates. These are fundamental but offer no chemical defense on their own.

Specialized Hazard Ratings

Chemical resistance is a specialized feature, much like Electrical Hazard (EH) protection or Electrostatic Discharge (ESD) properties. A shoe can have one of these features, a combination, or none at all. Never assume a shoe with a safety toe is also resistant to chemicals.

Understanding the Trade-offs and Limitations

Selecting the right footwear requires acknowledging that no single solution is perfect for every scenario.

No Shoe Resists Every Chemical

There is no "one-size-fits-all" chemical-proof boot. A material that is highly resistant to acids might degrade quickly when exposed to certain solvents. Always consult the manufacturer's chemical resistance chart.

Protection vs. Comfort and Breathability

The most robust chemical barriers are, by nature, non-porous. This means they are often less breathable than standard footwear, which can lead to discomfort over long shifts. Features like Coolmax linings or other moisture-wicking technologies are often included to mitigate this trade-off.

The Importance of Safety Classifications

Safety shoes are often categorized into protection classes (e.g., S1, S3, S5). These classifications define a suite of protective features. Understanding which class is required for your environment is a critical step in ensuring comprehensive safety.

How to Select the Right Chemical-Resistant Footwear

Your final choice must be guided by a clear assessment of your specific workplace hazards and daily tasks.

- If your primary focus is protection from low-risk, occasional splashes: A shoe with a high-quality waterproof liner and a durable outsole may be sufficient, but you must still verify its resistance to the specific liquids you handle.

- If your primary focus is direct handling of corrosive or hazardous chemicals: You must select footwear made from inherently resistant materials like specialized rubber or neoprene and consult the manufacturer's chemical resistance data for your specific hazards.

- If you work in a multi-hazard environment: Ensure the shoe's overall safety class and any additional ratings (like EH, ESD, or slip resistance) match all identified risks, not just the chemical one.

Ultimately, the right safety shoe is a non-negotiable piece of personal protective equipment that provides a reliable barrier against the specific hazards you face.

Summary Table:

| Feature | Key Materials | Primary Protection | Key Consideration |

|---|---|---|---|

| Upper Barrier | Specialized Rubber, Neoprene | Prevents liquid penetration and chemical burns | Must match specific chemicals in your environment |

| Outsole | Chemical-Resistant Compounds | Maintains slip resistance and integrity | Check manufacturer's chemical resistance chart |

| Construction | Sealed Seams, Vulcanized Build | Eliminates entry points for hazardous substances | Balances protection with breathability |

| Safety Class | S1, S3, S5 Ratings | Defines overall protective features (e.g., toe cap, slip resistance) | Ensure compliance with workplace hazards |

Need chemical-resistant safety shoes tailored to your specific hazards?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our expertise ensures your workforce gets durable, compliant protection against corrosive liquids, acids, and solvents—without compromising on comfort.

Contact us today for a customized solution that meets your exact safety standards!

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- Why is compliance with safety standards such as PN EN ISO 20347:2012 critical? Ensure Certified Workplace Protection

- What is the purpose of requiring subjects to wear anti-slip socks and tight-fitting sportswear? Optimize Sensor Data

- Why does the material performance of professional slip-resistant shoes offer superior safety? Hardware vs. Behavior

- How do industrial safety shoes contribute to safety in sugar production? Ensure High-Altitude Inspection Security

- Why are industrial-grade safety shoes mandatory in metallurgical workshops? Essential Protection for Extreme Environments