At its core, a vulcanized shoe is one constructed through a specific heat-treatment process that bonds the rubber sole to the canvas or fabric upper. This method, known as vulcanization, transforms soft, gummy rubber into a durable, flexible, and unified outsole. The result is a shoe with distinct characteristics prized for certain activities, particularly skateboarding.

The defining feature of a vulcanized shoe is its construction method: the entire shoe is essentially baked together, creating a single, cohesive unit. This process yields superior flexibility and board feel at the expense of cushioning and long-term durability.

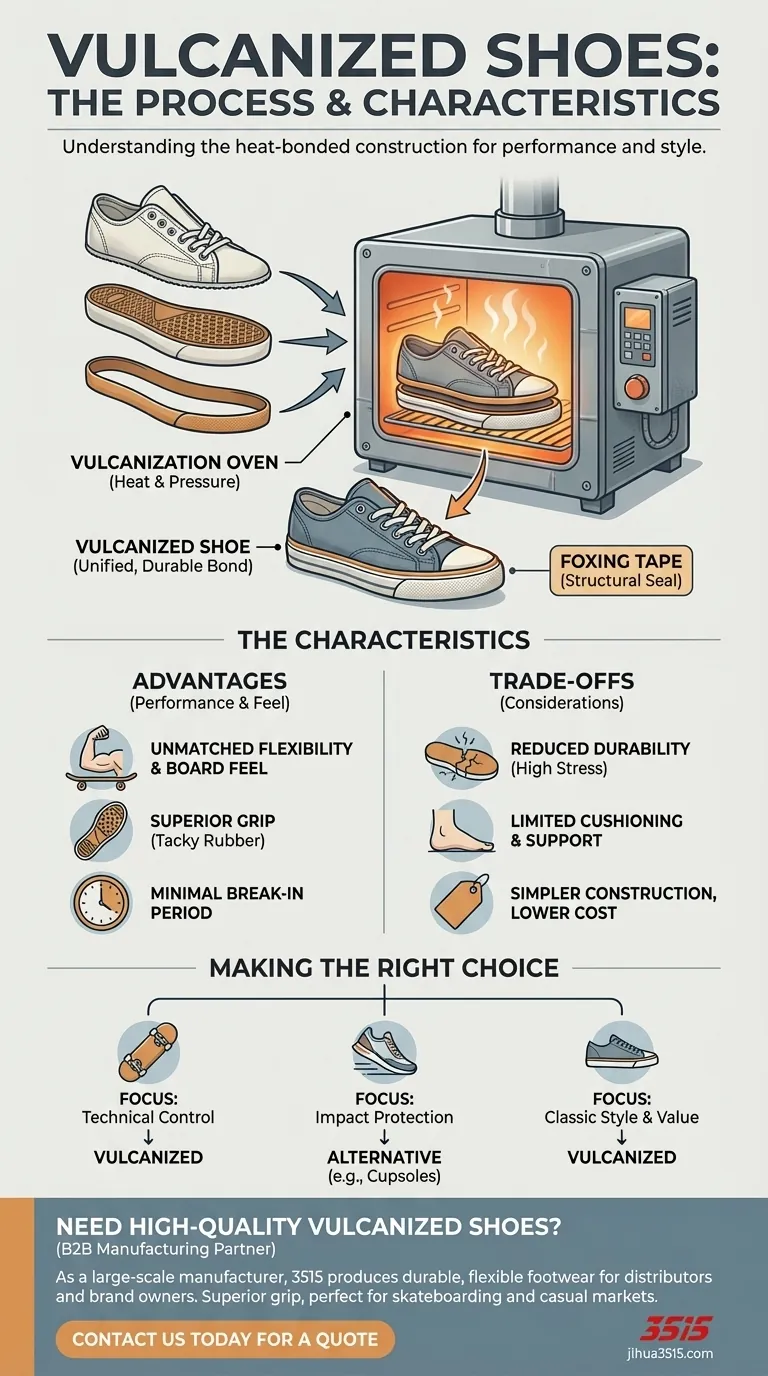

What is Vulcanization in Footwear?

The term "vulcanization" refers to a chemical process that cures rubber. In footwear, it’s a manufacturing method that uses heat and pressure to create a strong, lasting bond between the shoe's parts without the need for traditional stitching or heavy adhesives.

A Process of Heat and Pressure

Think of it like baking a cake. The shoe's upper (the fabric part), the rubber outsole, and the connecting rubber sidewall (known as foxing tape) are assembled. This complete unit is then placed in a special oven, or autoclave, and heated to a high temperature.

This "baking" process cures the rubber, causing it to harden and permanently fuse to the fabric upper and other rubber components. The result is a single, integrated piece.

The Signature "Foxing Tape"

A key visual identifier of a vulcanized shoe is the foxing tape. This is the rubber strip that wraps around the shoe's perimeter, covering the seam where the upper meets the sole. It's not just decorative; it's a structural part of the bond created during the heating process.

The Defining Characteristics of a Vulcanized Sole

The unique manufacturing process gives vulcanized shoes a specific feel and performance profile. These characteristics are the reason they have remained a staple for decades.

Unmatched Flexibility and Board Feel

Because the sole is thin and bonded directly to the upper as one piece, vulcanized shoes are incredibly flexible right out of the box. This provides an excellent board feel—the ability for a skateboarder to feel the board's shape and movements through their feet, allowing for precise control.

Superior Grip

The vulcanization process creates a soft and tacky rubber compound. This composition provides an exceptional grip on surfaces like a skateboard deck, making it easier to perform tricks and maintain balance.

Minimal Break-in Period

The inherent flexibility of the construction means vulcanized shoes require virtually no time to break in. They feel comfortable and ready for performance from the very first wear.

Understanding the Trade-offs

While vulcanized shoes offer clear advantages in feel and flexibility, this construction method involves significant compromises. Understanding these is critical to making an informed choice.

Reduced Durability

While vulcanization makes the rubber material itself more resistant to aging and cracking, the overall shoe design is less durable under high stress. The thin sole can wear through quickly, and the foxing tape can begin to peel away from the upper with repeated flexing.

Limited Cushioning and Support

The most significant drawback is the lack of support. The thin, flat sole offers minimal impact absorption and almost no arch support. This makes vulcanized shoes unsuitable for high-impact activities or for individuals who require more substantial footwear support.

Simpler Construction, Lower Cost

The vulcanization process is generally simpler and less material-intensive than other methods, such as cupsole construction. This often translates to a more accessible price point for the consumer.

Making the Right Choice for Your Goal

Ultimately, the choice between a vulcanized shoe and another style depends entirely on your priorities.

- If your primary focus is technical control and board feel: The flexibility and grip of a vulcanized shoe are ideal for activities like skateboarding where precision is key.

- If your primary focus is impact protection and all-day support: You should look for alternative constructions, like cupsoles, that offer superior cushioning and structure.

- If your primary focus is classic style and affordability: Vulcanized construction offers a timeless aesthetic and is often a more budget-friendly option for casual wear.

Choosing the right shoe begins with understanding how it’s made and what trade-offs that method entails.

Summary Table:

| Characteristic | Advantage | Trade-off |

|---|---|---|

| Construction | Heat-bonded sole & upper | Less durable under high stress |

| Flexibility | Excellent board feel & comfort | Minimal arch support & cushioning |

| Grip | Superior traction on surfaces | Softer sole wears faster |

| Cost & Style | Often more affordable, classic look | Simpler construction |

Need high-quality vulcanized shoes for your customers?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and flexible vulcanized footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure superior grip and board feel, perfect for skateboarding and casual markets.

Contact us today to discuss your manufacturing needs and get a competitive quote!

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

People Also Ask

- What factors determine the slip resistance of rubber-soled shoes? Tread, Compound & Design Explained

- What were traditional shoe soles made from before rubber? The History of Leather Soles

- What are the advantages of rubber soles in sneakers? Unmatched Grip, Durability & Comfort

- What causes white marks on rubber boots, and how can they be removed? A Guide to 'Blooming' & Boot Care

- How do rubber soles affect a shoe's appearance? Defining Your Shoe's Style and Formality