At its core, a toe cap is a rigid, protective reinforcement built into the front of a work boot. Its sole purpose is to shield your toes from serious injury caused by common workplace hazards, such as impact from falling objects or compression from heavy machinery. This component transforms a standard boot into a critical piece of Personal Protective Equipment (PPE).

The most important thing to understand is that the best toe cap isn't always the strongest one available. The right choice involves a critical trade-off between material properties like weight, conductivity, and the specific, certified level of protection required for your environment.

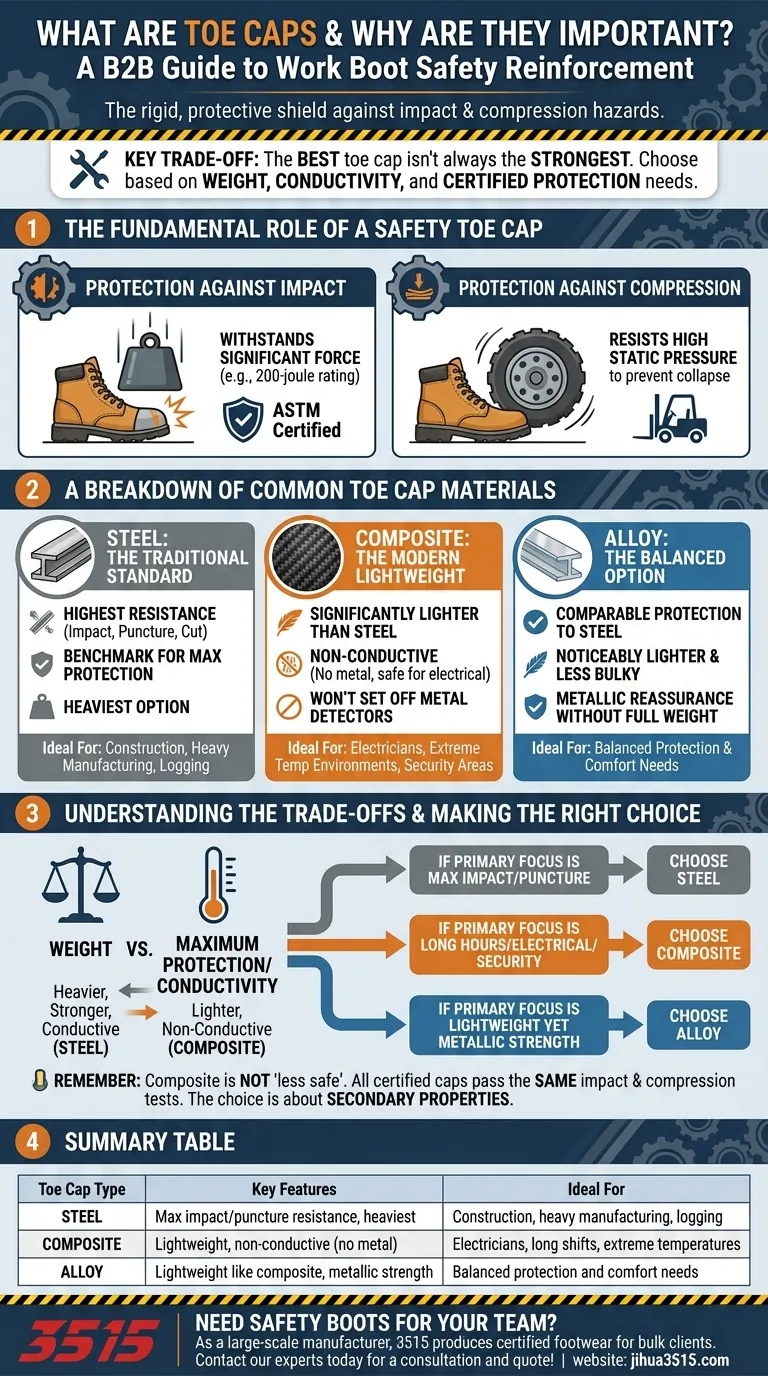

The Fundamental Role of a Safety Toe Cap

A safety toe cap isn't just a piece of hard material; it's an engineered component designed to meet rigorous standards and protect against two primary dangers.

Protection Against Impact

The most common hazard is an object falling onto the foot. Certified safety toes are tested to withstand a significant impact force.

Many safety standards, such as those from ASTM (American Society for Testing and Materials), specify a level of protection, often measured in joules. A 200-joule rating, for instance, indicates a very high level of defense.

Protection Against Compression

The other major threat is from rolling objects or machinery that could crush the foot. Toe caps are designed to resist a high degree of static pressure, preventing the toe box from collapsing.

This is critical for anyone working around vehicles, heavy equipment, or large, mobile material loads.

A Breakdown of Common Toe Cap Materials

While all certified safety toes must meet minimum impact and compression standards, the material used to achieve that protection has a major effect on the boot's performance, comfort, and suitability for certain jobs.

Steel: The Traditional Standard

Steel toe caps provide the highest level of resistance to impact, punctures, and side compression. They are often considered the benchmark for maximum protection.

Due to their exceptional strength, they are the classic choice for heavy-duty environments like construction, manufacturing, and logging.

Composite: The Modern Lightweight

Composite toes are made from non-metallic materials like carbon fiber, plastic, or Kevlar. Their primary advantage is being significantly lighter than steel.

Because they don't contain metal, they do not conduct electricity, heat, or cold, making them ideal for electricians or workers in extreme temperature environments. They also won't set off metal detectors.

Alloy: The Balanced Option

Alloy toes are crafted from lightweight metals like aluminum or titanium. They offer protection comparable to steel but in a noticeably lighter and less bulky package.

This provides a middle ground for those who want the reassurance of a metal toe cap without the full weight of traditional steel.

Understanding the Trade-offs

Choosing a toe cap material is not about picking a "good" or "bad" option. It's about understanding the compromises inherent in each design.

Weight vs. Maximum Protection

Steel offers unparalleled puncture and cut resistance but is also the heaviest option. Over a long shift, this extra weight can contribute to foot fatigue.

Composite and alloy toes provide certified impact protection at a reduced weight, significantly improving all-day comfort for workers who are constantly on their feet.

Thermal and Electrical Conductivity

This is a critical, non-negotiable factor for certain professions. Steel readily conducts temperature and electricity, making it unsuitable for some hazardous environments.

Composite materials are non-conductive, offering a vital layer of protection against electrical shock and better insulation in extreme cold or heat.

The Misconception of "Less Safe"

A common mistake is assuming that composite toes are inherently less safe than steel. Any boot with an official ASTM or other safety rating has passed the exact same impact and compression tests, regardless of material.

The choice is not about which is safer from impact, but which material's secondary properties best fit your specific job requirements.

Making the Right Choice for Your Work

To select the correct boot, you must align the toe cap's features with the primary demands and hazards of your workday.

- If your primary focus is maximum impact and puncture resistance: Steel toes remain the industry benchmark for heavy-duty environments like construction or logging.

- If your primary focus is working long hours on your feet or in security-sensitive areas: Composite toes offer certified protection with less weight and won't trigger metal detectors.

- If your primary focus is lightweight protection without sacrificing metallic strength: Alloy toes provide a balanced solution, offering steel-like protection in a lighter package.

- If your primary focus is working around extreme electrical or temperature hazards: Composite toes are the superior choice due to their non-conductive properties.

Choosing the right boot means understanding that true safety is a precise match between the tool and the task.

Summary Table:

| Toe Cap Type | Key Features | Ideal For |

|---|---|---|

| Steel | Maximum impact/puncture resistance, heaviest | Construction, heavy manufacturing, logging |

| Composite | Lightweight, non-conductive (no metal) | Electricians, long shifts, extreme temperatures |

| Alloy | Lightweight like composite, metallic strength | Balanced protection and comfort needs |

Need Safety Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. We can help you select or custom-manufacture the perfect boots—whether you need steel, composite, or alloy toes—to ensure your workforce is properly protected and comfortable.

Contact our experts today for a consultation and quote!

Visual Guide

Related Products

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- How do professional safety shoes provide protection in automotive workshop environments? Essential PPE for Workshop Safety

- What specific protective functions do safety shoes offer during high-risk tasks? Master Safety on Structural Beams

- What impact do steel toe caps have on toe skin health? Prevent Friction and Pressure in Your Safety Shoes

- Why are industrial safety shoes necessary for mining machinery maintenance? Protect Feet from Crushing and Punctures

- What role do high-sensitivity IoT devices play in footwear material handling? Powering Green Logistics & Efficiency