At a glance, the visible design features of a slip-resistant shoe sole are its material, its tread pattern, and its overall shape. The sole is typically made of a soft, pliable rubber compound, features an intricate pattern of small, interlocking shapes like circles or hexagons, and often has slightly rounded edges to help disperse liquids.

A truly slip-resistant shoe is a system designed to solve a physics problem: maintaining friction on a contaminated surface. The visible features are not for style; they are engineered to channel away liquids and maximize the sole's contact with the ground.

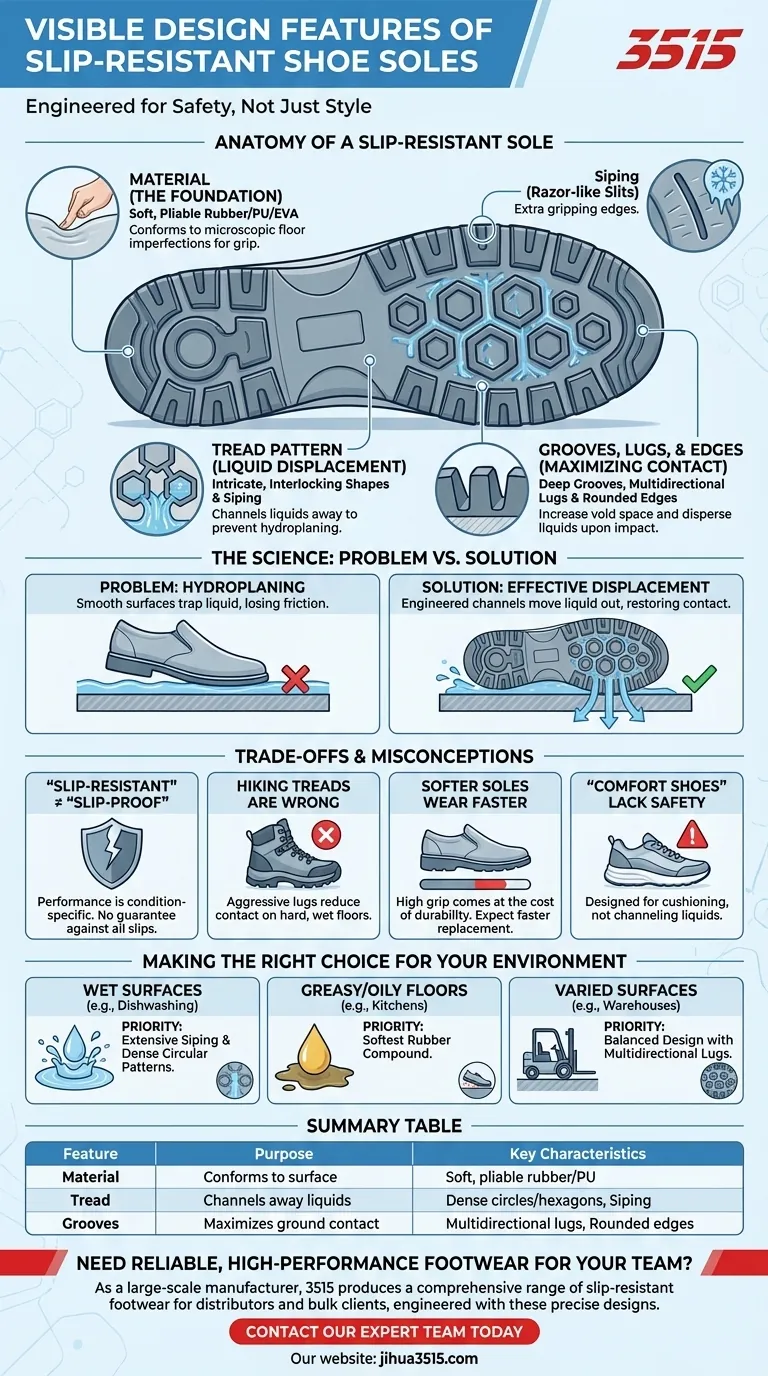

The Anatomy of a Slip-Resistant Sole

To reliably identify an effective slip-resistant shoe, you must understand how its core components work together. It’s the interaction between the material and the tread design that delivers true performance and safety.

The Critical Role of Material

The foundation of any slip-resistant shoe is a soft, high-friction outsole. You will typically see materials like high-grade rubber, polyurethane, or EVA (ethylene vinyl acetate).

These softer compounds are crucial because they can conform to the microscopic imperfections of a floor's surface. This flexibility dramatically increases the contact area, creating a stronger grip, much like the soft tires on a race car.

Tread Pattern: The Science of Liquid Displacement

The most obvious feature is the tread, but its specific design is what matters most. The primary goal of the tread is to prevent hydroplaning by efficiently channeling water, oil, and other liquids out from under the sole.

Effective patterns use interconnected channels to move liquid away from the center of the shoe. Look for dense patterns of circles, hexagons, or intricate squiggles. These shapes create multiple pathways for liquid to escape.

You may also see a feature called siping—thin, razor-like slits cut into the larger tread blocks. This technique, also used in vehicle tires, creates thousands of extra gripping edges that are especially effective on wet or icy surfaces.

Grooves, Lugs, and Edges

The depth and direction of the tread grooves are also key. Deeper grooves create more void space to hold and expel contaminants, increasing friction on the ground.

Many designs use multidirectional lugs, meaning the tread blocks are oriented to provide grip whether you are moving forward, backward, or side-to-side.

Finally, a slight rounding at the sole's edges helps prevent liquids from being trapped underneath the shoe upon footfall, allowing for more effective displacement.

Understanding the Trade-offs and Common Misconceptions

Not all features that look "grippy" are optimized for slip resistance in professional environments. Understanding the limitations is key to making an informed choice.

"Slip-Resistant" is Not "Slip-Proof"

This is the most important distinction. No shoe can guarantee 100% protection against all slips on all surfaces. Slip resistance is rated for specific conditions (e.g., water on tile), and performance can decrease significantly with other contaminants like thick grease or flour dust.

The Myth of Aggressive Hiking Treads

A deep, aggressive tread like one found on a hiking boot is designed for soft, uneven surfaces like dirt and mud. On a hard, wet, or greasy floor, these large, rigid lugs can actually reduce surface contact and decrease grip.

Softer Soles and Durability

The very softness that makes a rubber sole so effective at gripping also makes it less durable. A high-performance slip-resistant sole will likely wear down faster than a harder, standard work boot sole, requiring more frequent replacement to maintain safety.

The "Comfort Shoe" Trap

Many walking or comfort-focused shoes have soft, flexible soles. However, they are engineered for forward motion and cushioning, not for channeling away liquids. They typically lack the specific tread patterns needed for a hazardous work environment.

Making the Right Choice for Your Environment

Your specific work environment dictates the most important features to look for in a shoe's sole.

- If your primary focus is wet surfaces (e.g., dishwashing areas, frequent spills): Prioritize soles with extensive siping and dense, circular tread patterns designed to quickly displace water.

- If your primary focus is greasy or oily floors (e.g., commercial kitchens): Look for the softest rubber compound you can find, as its ability to conform to the floor is critical for cutting through viscous liquids.

- If your primary focus is varied surfaces with occasional hazards (e.g., warehouses, healthcare): Seek a balanced design with a durable rubber blend and a multidirectional tread pattern that provides reliable, all-around traction.

By understanding these core design principles, you can confidently evaluate a shoe's sole and choose the right protection for your needs.

Summary Table:

| Feature | Purpose | Key Characteristics |

|---|---|---|

| Material | Conforms to floor surfaces | Soft, pliable rubber or polyurethane |

| Tread Pattern | Channels away liquids | Dense patterns of circles, hexagons, and siping |

| Grooves & Edges | Maximizes ground contact | Multidirectional lugs, rounded edges |

Need reliable, high-performance footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of slip-resistant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, engineered with the precise material and tread designs discussed here to protect your workforce.

We can help you source the right footwear for any environment—from greasy kitchens to wet hospital floors.

Contact our expert team today for a consultation and see how we can enhance your safety program.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Safety Shoes with Rotating Buckle Safety Sneakers

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Customizable Slip-On Safety Shoes Direct from the Factory for Wholesale

People Also Ask

- Is safety-toe as good as steel toe? Choose the Right Protection for Your Job

- How long can you wear safety boots? The Lifespan is Determined by Wear, Not Time

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene