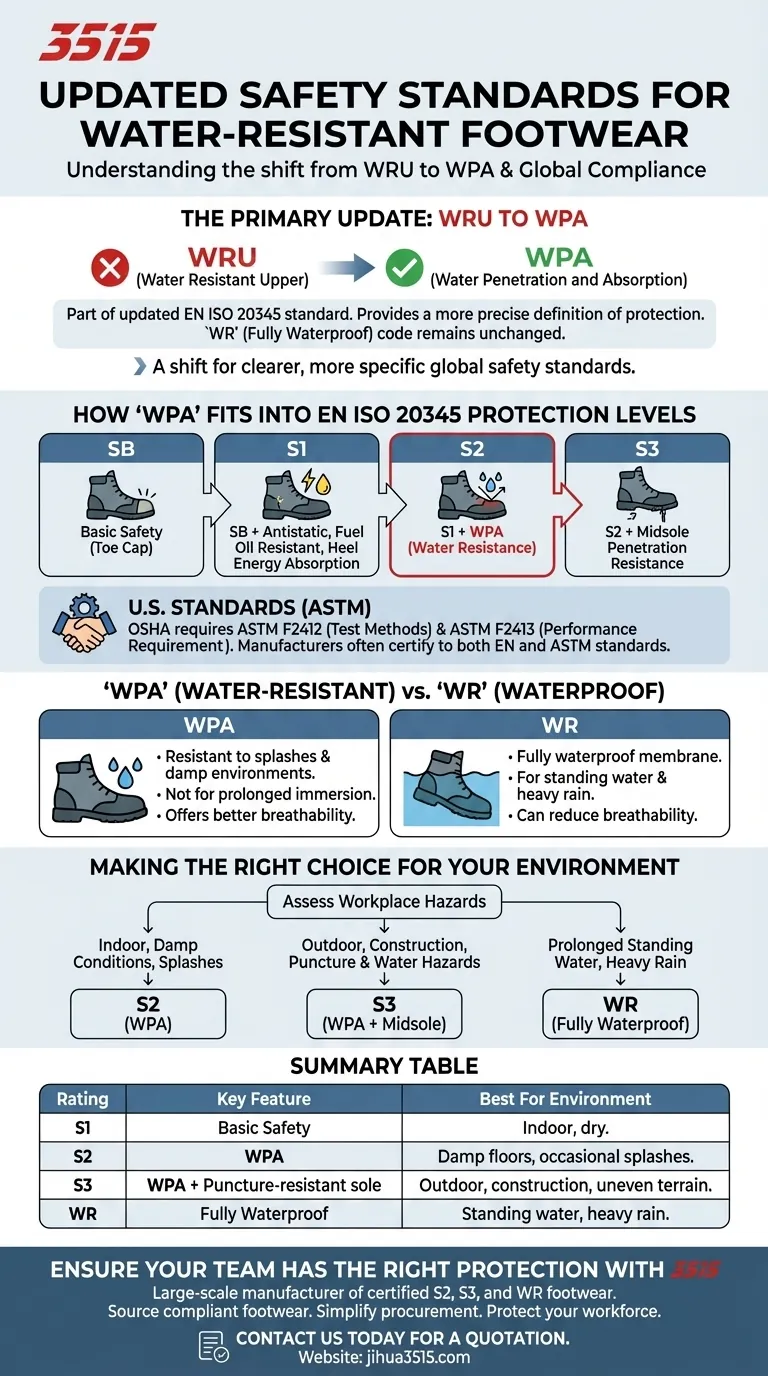

The primary update you need to know is that the safety code for water-resistant footwear has changed from WRU (Water Resistant Upper) to WPA (Water Penetration and Absorption). This change is part of the updated EN ISO 20345 standard, designed to provide a more precise definition of protection. The code for fully waterproof footwear, WR, remains unchanged.

The shift from

WRUtoWPAis more than a simple name change; it reflects a global effort to create clearer, more specific safety standards. Understanding this code in the context of the broader safety framework is crucial for ensuring true compliance and worker protection.

How 'WPA' Fits Into Global Safety Standards

Safety footwear is governed by a system of codes that specify different types of protection. The new WPA designation is a component within this larger structure, primarily defined by the European EN ISO 20345 standard, which is recognized globally.

The EN ISO 20345 Protection Levels

The most common way to categorize safety footwear is through the S ratings. Water resistance is a key feature that differentiates the foundational levels.

- SB: This is the basic safety standard, requiring only a protective toe cap.

- S1: Includes

SBfeatures plus antistatic properties, fuel oil resistance, and energy absorption in the heel. - S2: Includes all

S1features plus water resistance (WPA). This is the first level that guarantees protection against water penetration and absorption. - S3: Includes all

S2features plus midsole penetration resistance to protect against sharp objects like nails.

The change to WPA simply clarifies the specific type of water protection offered in footwear rated S2 and above.

U.S. Standards (ASTM)

In the United States, the Occupational Safety and Health Administration (OSHA) requires that safety footwear meets the standards set by ASTM International.

- ASTM F2412: This standard outlines the test methods for footwear protection, such as impact and compression resistance tests for the toe cap.

- ASTM F2413: This standard specifies the performance requirements. Footwear that meets this standard will be labeled with its specific protections (e.g., I for impact, C for compression).

While the ASTM standards do not use the S rating system, manufacturers often test and certify their footwear to both EN and ASTM standards to serve a global market.

'WPA' (Water-Resistant) vs. 'WR' (Waterproof)

It is critical to distinguish between these two ratings, as they offer fundamentally different levels of protection.

- WPA (Water Penetration and Absorption): This rating indicates the upper part of the footwear is resistant to water. It is suitable for damp environments and protection from splashes but not for prolonged immersion.

- WR (Waterproof): This rating signifies the entire shoe is constructed with a waterproof membrane to prevent any water from entering. This is the standard required for working in standing water or heavy rain.

Understanding the Trade-offs

Choosing the right footwear isn't just about meeting a standard; it's about balancing protection with practicality.

Protection vs. Breathability

Higher levels of water protection often come at the cost of breathability. A fully waterproof (WR) boot is excellent at keeping water out but can also trap sweat, leading to discomfort. A water-resistant (WPA) boot offers a compromise, providing adequate protection for many conditions while allowing for better airflow.

Cost vs. Necessity

As protection levels increase (e.g., moving from an S1P to an S3 shoe), the cost typically rises. Over-specifying footwear by choosing a higher rating than the workplace hazards demand is an unnecessary expense. A thorough risk assessment is key to cost-effective compliance.

The Limits of a Standard

A safety rating is a benchmark, not an absolute guarantee for all conditions. A WPA rated boot protects against water under specific test conditions. Real-world factors like wear and tear, exposure duration, and specific chemicals can affect performance.

Making the Right Choice for Your Environment

Use your workplace risk assessment to determine the necessary level of protection.

- If your primary focus is indoor work in damp conditions with occasional splashes: Footwear rated

S2or higher, which includes theWPAstandard, provides the necessary protection. - If your primary focus is construction or outdoor work with puncture and water hazards: You must select

S3footwear, which combines midsole penetration resistance withWPAwater resistance. - If your primary focus is prolonged work in standing water or heavy rain: Water-resistant

WPAfootwear is insufficient. You must choose footwear with theWR(Waterproof) designation. - If your primary focus is U.S. compliance for general hazards: Ensure the footwear meets ASTM F2413 requirements, then check for additional manufacturer specifications on water resistance that align with your specific needs.

Understanding these specific codes allows you to move beyond simple compliance and actively select the precise protection your team needs to stay safe and productive.

Summary Table:

| Rating | Key Feature | Best For Environment |

|---|---|---|

| S1 | Basic safety, antistatic | Indoor, dry conditions |

| S2 | WPA (Water Resistant Upper) | Damp floors, occasional splashes |

| S3 | WPA + Puncture-resistant sole | Outdoor, construction, uneven terrain |

| WR | Fully Waterproof | Standing water, heavy rain |

Ensure Your Team Has the Right Protection

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of S2, S3, and WR-rated shoes and boots that meet the latest EN ISO 20345 and ASTM standards.

We help you:

- Source compliant footwear with the correct WPA or WR ratings for your specific hazards.

- Simplify procurement with reliable, high-volume production and consistent quality.

- Protect your workforce with durable footwear designed for real-world conditions.

Contact us today to discuss your requirements and receive a quotation: Get in Touch

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium KPU Injection Athletic Style Safety Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- Are employers required to provide steel-toe rubber boots at no cost to employees? Yes, under OSHA rules.

- What type of footwear is required in meatpacking and poultry plants due to slippery conditions? Essential Safety Boots for Slippery Floors

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health