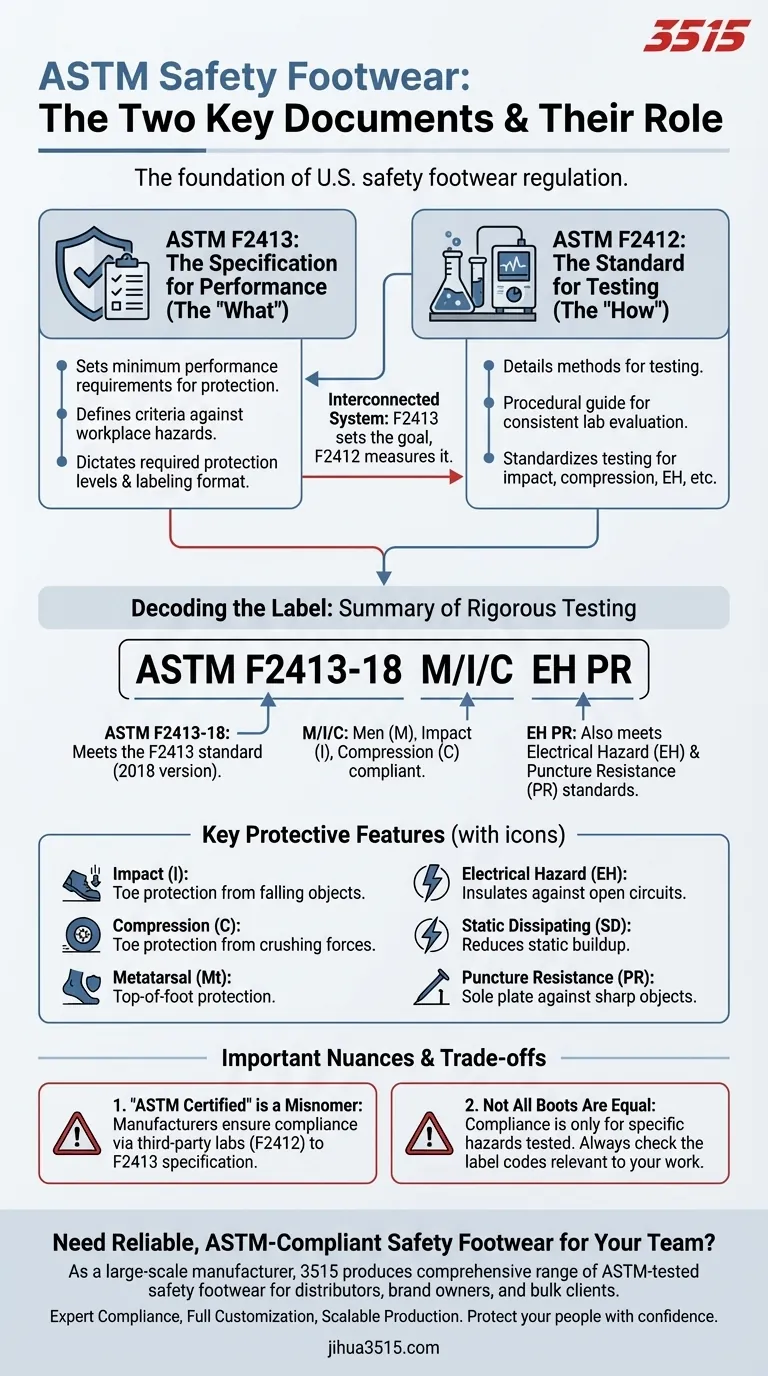

The two primary ASTM International documents that govern safety footwear are ASTM F2413 and ASTM F2412. These two standards form the foundation of safety footwear regulation in the United States. ASTM F2413 establishes the minimum performance requirements for protection, while ASTM F2412 defines the precise laboratory methods used to test and verify that performance.

In simple terms, think of it this way: ASTM F2413 is the "what"—the specification that defines a safe boot. ASTM F2412 is the "how"—the rulebook for the tests that prove it. A boot cannot be compliant with one standard without the other.

Deconstructing the Core Standards

To truly understand safety footwear, you must see these two standards as a single, interconnected system. One sets the goal, and the other provides the means to measure it.

ASTM F2413: The Specification for Performance

This is the master document that outlines the minimum requirements for the design, performance, testing, and classification of protective footwear.

It defines the specific criteria for features designed to protect against a variety of workplace hazards. This standard is what dictates the required level of protection.

Critically, ASTM F2413 also specifies the exact format for labeling compliant footwear, allowing you to identify its protective capabilities at a glance.

ASTM F2412: The Standard for Testing

This document details the methods for testing safety footwear. It is the procedural guide for laboratories, ensuring that every boot is evaluated consistently and reliably.

ASTM F2412 provides exact instructions on how to conduct tests for impact resistance, compression, electrical hazards, and other protective features.

By standardizing the testing process, it eliminates variables and guarantees that a boot tested in one facility would achieve the same results in another.

What "ASTM F2413" Means on Your Boot

The ultimate purpose of these standards is to create a clear and reliable system for the end-user. When you see a label on a boot, it is a summary of rigorous testing against specific hazards.

The Key Protective Features

ASTM F2413 outlines requirements for several distinct protective categories. The most common ones you will encounter are:

- Impact (I): Protects the toe area from falling objects.

- Compression (C): Protects the toe area from rolling objects or crushing forces.

- Metatarsal (Mt): Provides additional protection for the top of the foot, beyond the standard safety toe.

- Electrical Hazard (EH): Insulates the wearer from the ground to protect against open electrical circuits.

- Static Dissipating (SD): Reduces the buildup of static electricity to prevent sparking.

- Puncture Resistance (PR): Includes a plate in the sole to protect the foot from sharp objects from below.

Reading the Label

The label inside the boot provides a concise code detailing its specific protections. A typical label might read: ASTM F2413-18 M/I/C EH PR.

- ASTM F2413-18: Indicates the boot meets the F2413 standard, updated in 2018.

- M/I/C: Signifies it is for Men (M), and meets both Impact (I) and Compression (C) standards.

- EH PR: Indicates it also meets the specific requirements for Electrical Hazard and Puncture Resistance.

Understanding the Trade-offs and Nuances

Simply knowing the document numbers is not enough. True safety requires understanding the limitations and realities of the system.

"ASTM Certified" is a Misnomer

ASTM International develops standards but does not certify products. Manufacturers are responsible for ensuring their footwear meets the standard.

They typically use independent, third-party labs that follow the ASTM F2412 test methods to verify compliance with the F2413 specification.

Not All Safety Boots Are Created Equal

A boot's compliance with the ASTM F2413 standard is not a blanket approval. It is only compliant for the specific hazards it was tested and rated for.

A boot can meet the standard for Impact (I) and Compression (C) but offer zero protection against electrical hazards if it is not also rated for EH. Always check the label for the specific codes relevant to your work environment.

The Global Context

While ASTM standards are predominant in the United States, other countries and regions have their own governing bodies, such as ISO (International), AS/NZS (Australia/New Zealand), and JIS (Japan). Many of these standards are based on similar principles to ASTM.

Making the Right Choice for Your Goal

Your choice of footwear must be dictated by a clear assessment of your specific workplace hazards.

- If your primary focus is construction or heavy industry: You must prioritize footwear with Impact (I), Compression (C), and Puncture Resistance (PR) ratings.

- If your primary focus is work as an electrician: Your non-negotiable requirement is a boot with a clearly marked Electrical Hazard (EH) rating.

- If your primary focus is logistics or manufacturing: Footwear meeting the baseline Impact (I) and Compression (C) standards is essential to protect against falling items and moving equipment.

Understanding these standards transforms you from a consumer into an informed professional capable of making a critical safety decision.

Summary Table:

| Standard | Purpose | Key Focus |

|---|---|---|

| ASTM F2413 | Performance Requirements | Defines the "what": minimum levels of protection (Impact, Compression, EH, etc.). |

| ASTM F2412 | Test Methods | Defines the "how": standardized laboratory procedures to verify performance. |

Need Reliable, ASTM-Compliant Safety Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-tested safety footwear for distributors, brand owners, and bulk clients. We ensure every pair meets the rigorous standards of F2413 and F2412, providing the certified protection your workforce needs.

We offer:

- Expert Compliance: Deep understanding of ASTM standards for accurate labeling and performance.

- Full Customization: Tailor footwear with the specific protection codes (I/C, EH, PR, Mt) required for your industry.

- Scalable Production: Capabilities to fulfill large orders for all types of safety shoes and boots with consistent quality.

Protect your people with confidence. Contact our experts today to discuss your safety footwear requirements.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What is the purpose of requiring subjects to wear anti-slip socks and tight-fitting sportswear? Optimize Sensor Data

- Why does the material performance of professional slip-resistant shoes offer superior safety? Hardware vs. Behavior

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today

- How do athletic-style safety shoes balance flexibility and safety? Perfect Agility for Active Professionals