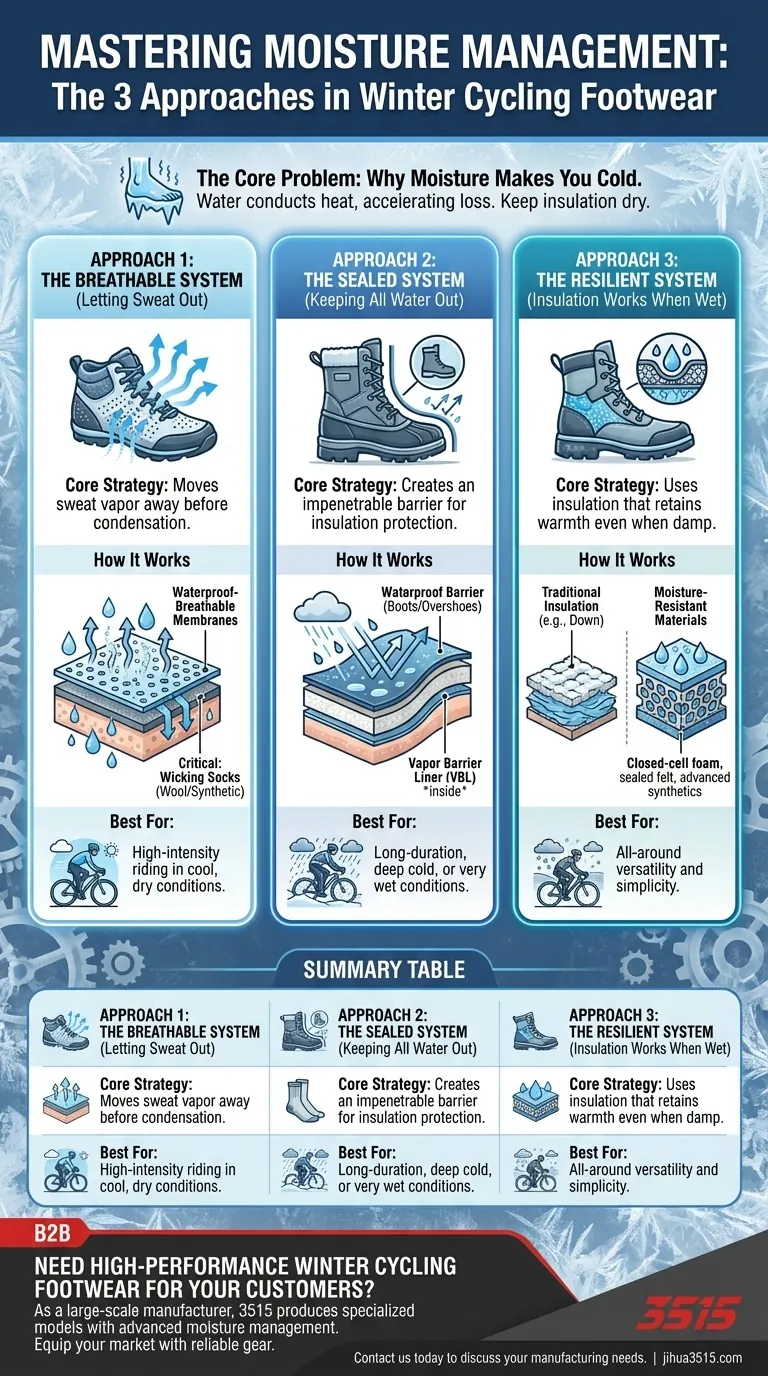

The three primary approaches to managing moisture in winter cycling footwear are: allowing sweat to escape through breathable materials, blocking external water from reaching insulation, and using insulation that remains effective even when damp. Each strategy tackles the core problem of heat loss caused by moisture, but they are best suited for different conditions and rider needs.

The central challenge in keeping feet warm is not insulation alone, but moisture control. Because water conducts heat away from your body far more effectively than air, any moisture—from sweat or the environment—that saturates your insulation will rapidly lead to cold feet.

The Core Problem: Why Moisture Makes You Cold

Before examining the solutions, it's critical to understand the enemy. Your goal is to maintain a layer of warm, dry air around your feet, which is what insulation is designed to do. Moisture defeats this in two ways.

The Physics of Heat Loss

Water is a highly effective thermal conductor. When your socks and the insulation in your boots become wet, they no longer trap air effectively. Instead, they conduct warmth away from your feet, drastically accelerating heat loss and making you feel cold even in moderately cool temperatures.

Two Sources of Moisture

The moisture you must manage comes from two distinct sources. Internal moisture is sweat produced by your feet, especially during high-exertion riding. External moisture includes rain, melting snow, and slush from the road. An effective system must account for both.

Approach 1: The Breathable System (Letting Moisture Out)

This strategy prioritizes moving sweat vapor away from your foot before it can condense and saturate your sock and insulation.

How It Works

This system relies on waterproof-breathable membranes. These materials contain microscopic pores that are large enough to allow individual water vapor molecules (sweat) to pass through and escape, but too small for larger liquid water droplets (rain, slush) to penetrate from the outside.

The Critical Role of Wicking Socks

A breathable system is only as good as the socks inside it. Wool or synthetic wicking socks are essential. They pull moisture off your skin and transport it toward the boot's membrane, allowing the system to "breathe" effectively. Cotton socks, in contrast, absorb and hold moisture, rendering the breathable membrane useless.

Approach 2: The Sealed System (Keeping All Water Out)

This approach focuses on creating an impenetrable barrier, preventing any moisture from either the outside or the inside from compromising the boot's primary insulation.

The Waterproof Barrier

The first layer of defense is a completely waterproof exterior. This can be achieved with non-breathable winter cycling boots or, more commonly, by adding waterproof overshoes (booties) over your existing shoes. This effectively shields the entire boot from external water.

Managing Sweat with a Vapor Barrier Liner (VBL)

Sealing the boot from the outside also traps sweat on the inside. The solution is a Vapor Barrier Liner (VBL). This is a non-breathable sock or liner worn between a thin liner sock and your main insulating sock. The VBL stops your sweat from ever reaching and dampening your primary insulation, keeping it perfectly dry and effective. Your foot will be damp inside the VBL, but your insulation remains uncompromised.

Approach 3: The Resilient System (Insulation That Works When Wet)

This strategy accepts that some moisture may be present but mitigates its impact by using insulation that doesn't fail when damp.

The Failure of Traditional Insulation

Many insulating materials, like down or open-cell foam, rely on trapping air within their lofty structure. When they get wet, they collapse, lose their loft, and their insulating value plummets.

Moisture-Resistant Materials

This approach utilizes materials that are inherently resistant to moisture. Closed-cell foam is a prime example, as its structure prevents it from absorbing water. Other options include sealed felt or advanced synthetic batting, which maintain their structure and a significant portion of their insulating properties even when damp.

Understanding the Trade-offs

No single approach is perfect for every scenario. Choosing the right one depends on understanding their limitations.

Breathable Systems

A breathable system is excellent for managing sweat in cool, dry conditions. However, the membrane can be overwhelmed in a sustained downpour or when submerged in slush, a phenomenon known as "wetting out."

Sealed Systems (with VBLs)

This is the most reliable method for deep cold or extremely wet conditions, as it guarantees your insulation stays dry. The primary trade-off is comfort; trapping sweat inside the VBL can make your feet feel clammy, which some riders dislike.

Resilient Insulation

This is a forgiving, "jack-of-all-trades" approach. Its main downside is that while it performs better than compromised traditional insulation, it may not be as warm for its weight as a perfectly dry, high-loft insulation system.

Choosing the Right Approach for Your Ride

Your choice should be dictated by your riding intensity, duration, and the weather conditions you face.

- If your primary focus is high-intensity riding in cool, dry conditions: A breathable system with quality wicking socks is ideal for managing sweat.

- If your primary focus is long-duration riding in deep cold or very wet/slushy conditions: A sealed system with a vapor barrier liner offers the most reliable warmth by protecting your insulation.

- If your primary focus is all-around versatility and simplicity: Footwear using resilient, moisture-resistant insulation provides a dependable and forgiving solution.

Mastering moisture management is the definitive step toward achieving truly warm and comfortable winter cycling.

Summary Table:

| Approach | Core Strategy | Best For |

|---|---|---|

| Breathable System | Lets sweat vapor escape | High-intensity riding in cool, dry conditions |

| Sealed System (with VBL) | Blocks all external/internal moisture | Long rides in deep cold or very wet conditions |

| Resilient Insulation | Uses materials that work even when damp | All-around versatility and simplicity |

Need high-performance winter cycling footwear for your customers?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including specialized winter cycling models designed with advanced moisture management technologies. We can help you equip your customers with the right gear for any condition.

Contact us today to discuss your manufacturing needs and bring reliable, high-quality footwear to your market.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Grain Leather Safety Boots for Bulk Supply

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- Why do operations involving heavy fruit bunches and 'gancu' require anti-smash and anti-puncture safety boots?

- Why are professional safety shoes required during heavy-duty girder erection? Essential Protection for Infrastructure

- What is the core protective function of steel-toe safety shoes in preventing lower limb injuries caused by chainsaws?

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What role do industrial safety shoes with steel toes or composite protective layers play in high-risk manufacturing?