For security guard boots, the most critical sole and heel considerations are slip resistance, puncture protection, and material composition tailored to your specific work environment. These elements form the foundation of your safety and comfort, directly impacting your ability to stand for long hours, move quickly, and navigate unpredictable hazards on patrol. The right choice prevents injury and reduces fatigue over a long shift.

Choosing the right boot sole isn't about finding one "best" material. It's about strategically matching the specific properties of the sole—like rubber's superior grip or polyurethane's lightweight durability—to the unique demands of your patrol environment, from polished indoor floors to rugged outdoor terrain.

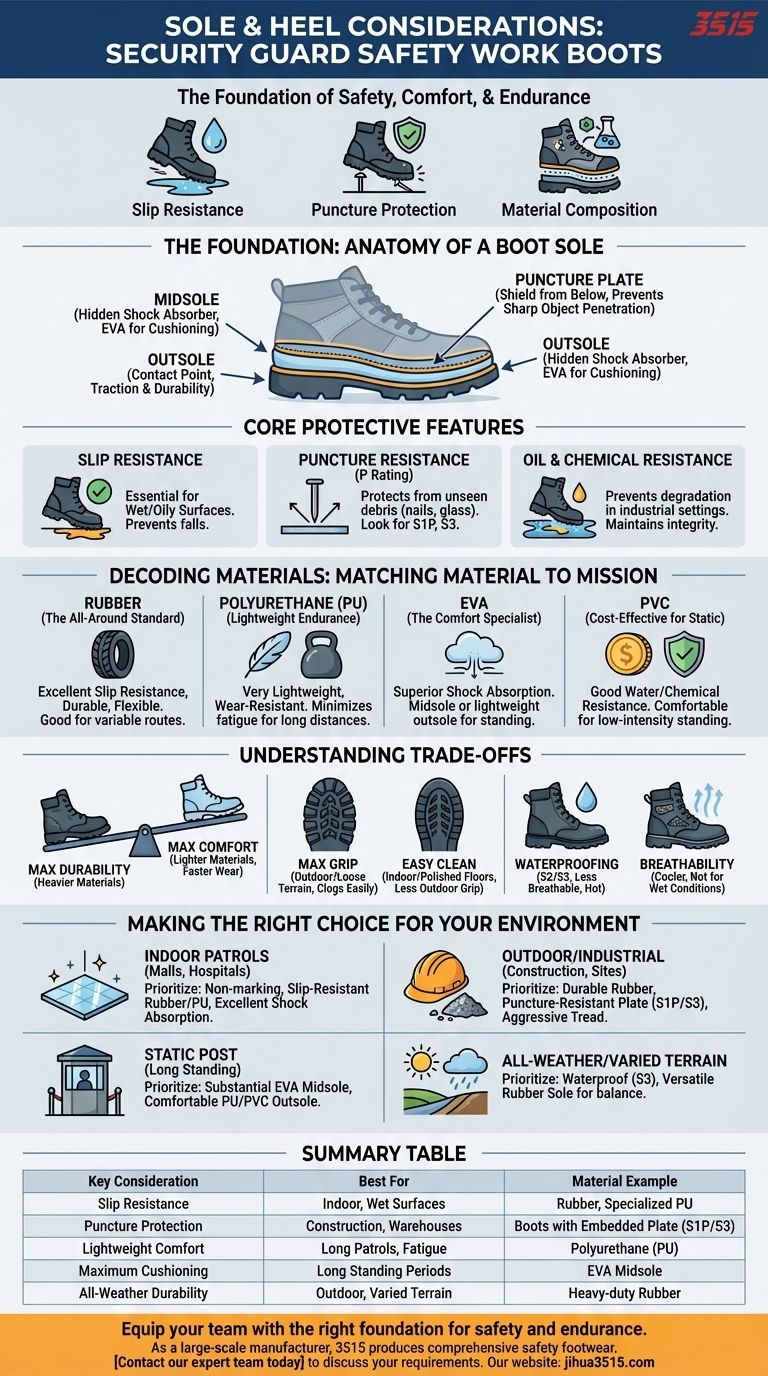

The Foundation: Understanding Sole and Heel Components

Before selecting a material, it's crucial to understand how a boot's base is constructed. Each layer serves a distinct purpose that contributes to your overall safety and comfort.

The Outsole: Your Direct Contact Point

The outsole is the part of the boot that makes contact with the ground. Its primary jobs are to provide traction and durability. The material and tread pattern here determine how well the boot grips various surfaces.

The Midsole: The Hidden Shock Absorber

Located between the outsole and your foot, the midsole provides cushioning and absorbs impact. A quality midsole, often made of materials like EVA, is essential for preventing foot fatigue during long periods of standing or walking.

Puncture Plate: Your Shield from Below

In many safety boots, a puncture-resistant plate is embedded within the sole structure. This feature is critical for guards who work in environments where sharp objects like nails, glass, or metal fragments could be on the ground.

Core Protective Features Demystified

The function of the sole goes far beyond simply walking. For a security professional, it is a piece of personal protective equipment with specific, non-negotiable features.

Slip Resistance is Essential

A slip-resistant sole is the most fundamental safety feature. Look for boots that are rated for performance on wet or oily surfaces, which are common hazards in both indoor and outdoor environments.

Puncture Resistance for Unpredictable Hazards

Working on construction sites, in warehouses, or even in urban patrol environments exposes you to sharp debris. A puncture-resistant sole, indicated by a P in its safety rating (e.g., S1P, S3), protects you from these unseen dangers.

Resistance to Oil and Chemicals

For guards in industrial, manufacturing, or garage settings, oil- and acid-resistant soles are vital. These specialized materials prevent the sole from degrading upon contact with corrosive substances, maintaining its structural integrity and grip.

Decoding Sole Materials: Matching Material to Mission

The material of your boot's outsole dictates its performance. Each has a unique profile of strengths and weaknesses that makes it suitable for different security roles.

Rubber: The All-Around Standard

Rubber is a popular choice for its excellent slip resistance on a wide variety of surfaces. It is flexible, waterproof, and highly durable, making it a reliable option for variable patrol routes.

Polyurethane (PU): The Lightweight Endurance Option

PU soles are known for being very lightweight and wear-resistant. This makes them an excellent choice for guards who cover a lot of ground and want to minimize fatigue without sacrificing durability.

EVA (Ethylene Vinyl Acetate): The Comfort Specialist

EVA is a foam-like material prized for its superior shock absorption. While it is typically used in the midsole for cushioning, some lightweight boots use it in the outsole for maximum comfort during static, standing-intensive posts.

PVC (Polyvinyl Chloride): The Cost-Effective Choice for Static Posts

PVC is a cost-effective and comfortable option. It provides good resistance to water and chemicals, making it suitable for guards who spend long hours standing in a relatively stable, low-intensity environment.

Understanding the Trade-offs

No single boot is perfect for every scenario. Understanding the inherent trade-offs in materials and design is key to making an informed decision.

Durability vs. Weight

Heavier, denser materials like solid rubber offer maximum durability and protection but can contribute to leg fatigue over a 12-hour shift. Lighter materials like PU and EVA significantly improve comfort but may wear out faster under harsh conditions.

Grip vs. Clogging

An aggressive, deep-lugged tread pattern is excellent for grip on loose dirt or gravel outdoors. However, that same pattern can pick up and track mud and debris, making it less ideal for guards who frequently move between outdoor and clean indoor areas.

Waterproofing vs. Breathability

While a fully waterproof boot (rated S2 or S3) is essential for outdoor work in wet climates, it often comes at the cost of breathability. This can lead to sweaty, uncomfortable feet during long patrols in warmer conditions.

Making the Right Choice for Your Environment

Your daily tasks and typical patrol area are the ultimate guide to selecting the right sole and heel configuration.

- If your primary focus is indoor patrols (e.g., malls, hospitals): Prioritize a non-marking, slip-resistant rubber or PU sole with excellent shock absorption for comfort on hard floors.

- If your primary focus is outdoor or industrial sites (e.g., construction, manufacturing): A durable rubber sole with a puncture-resistant plate (S1P or S3 rating) and an aggressive tread is essential.

- If your primary focus is long periods of standing at a static post: Look for boots with a substantial EVA midsole and a comfortable PU or PVC outsole to minimize fatigue.

- If your primary focus is all-weather conditions and varied terrain: A waterproof boot (S3 rating) with a versatile rubber sole offers the best balance of protection and grip.

Ultimately, investing in the correct sole and heel is a direct investment in your safety, endurance, and professional effectiveness on every shift.

Summary Table:

| Key Consideration | Best For | Material Example |

|---|---|---|

| Slip Resistance | Indoor patrols, wet surfaces | Rubber, specialized PU |

| Puncture Protection | Construction sites, warehouses | Boots with embedded plate (S1P/S3 rating) |

| Lightweight Comfort | Long patrols, minimizing fatigue | Polyurethane (PU) |

| Maximum Cushioning | Long periods of standing | EVA Midsole |

| All-Weather Durability | Outdoor, varied terrain | Heavy-duty Rubber |

Equip your team with the right foundation for safety and endurance.

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of security and tactical boots, engineered with the precise sole and heel technologies detailed in this guide. We can help you source or customize the perfect boots to meet the specific demands of your security personnel's work environment.

Contact our expert team today to discuss your requirements and get a quote.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium KPU Injection Athletic Style Safety Shoes

People Also Ask

- Why is the anti-smash feature essential in palm oil processing areas? Ensure Worker Safety from Heavy Machinery Risks

- How does the molding method work in safety shoes manufacturing? Unlock Unmatched Durability and Protection

- What is the importance of safety equipment in the workplace? Boost Safety & Productivity

- What role does professional footwear play in protecting workers? Enhance Stability During Trunk Rotation and Bending

- What protective function do slip-resistant safety shoes provide in confined spaces? Maximize Stability & Grip

- What safety features should be considered in work shoes? Match the Right Protection to Your Job Hazards

- What are the advantages of composite toe boots compared to steel toe boots? Lighter, Safer & Metal-Free.

- Why is specialized sole friction design necessary for safety footwear on ice? Engineered Solutions for Extreme Traction