For a carpenter, the ideal work boot is a specialized tool that must provide a non-negotiable blend of safety, long-term comfort, and job-specific functionality. The most critical features are a protective safety toe, a slip-resistant and puncture-resistant sole, and robust ankle support. Critically, these safety elements must be paired with all-day comfort features, such as a well-cushioned insole and a wedge sole designed to distribute weight evenly and fight fatigue.

Choosing the right work boot isn't about finding the toughest one available; it's about selecting a precise system of support for your feet. The best choice for a carpenter balances mandatory safety requirements with specific design elements that directly combat the physical strain of standing, climbing, and working on varied surfaces.

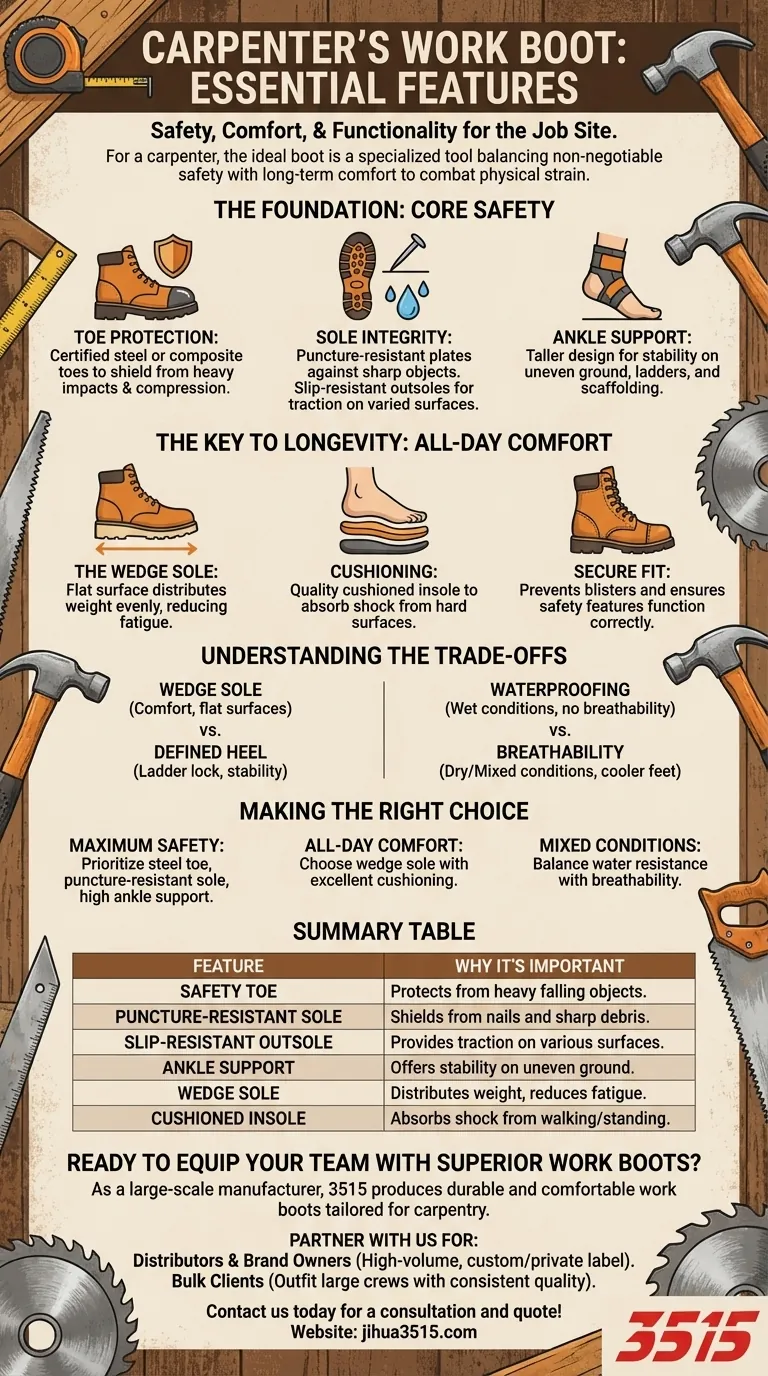

The Foundation: Core Safety Features

A carpenter's work environment is filled with potential hazards, from falling objects to sharp debris on the ground. Your boots are your first line of defense.

Beyond the Basics: Toe Protection

All professional work boots must have certified toe protection. This feature is designed to shield your feet from heavy impacts and compression.

Steel toes are the traditional standard, offering maximum protection. They are a reliable choice for heavy construction environments.

The Unseen Shield: Sole Integrity

The sole of your boot does much more than just provide a walking surface. It needs to protect you from below and keep you upright.

Look for a puncture-resistant plate, often made of steel, embedded in the sole to prevent nails and other sharp objects from piercing through.

A slip-resistant outsole is also mandatory. Carpenters work on everything from dusty plywood to damp concrete, and a high-traction sole prevents dangerous falls.

Stability on Uneven Ground: Ankle Support

Job sites are rarely flat, even surfaces. Navigating unfinished floors, scaffolding, and ladders requires exceptional stability.

Taller boots that extend over the ankle provide crucial support, helping to prevent twists and sprains. This design gives you more confidence and control with every step.

The Key to Longevity: All-Day Comfort

Safety features are useless if a boot is too uncomfortable to wear. For a carpenter who spends 8-10 hours on their feet, comfort is a direct contributor to endurance and work quality.

The Carpenter's Choice: The Wedge Sole

Many carpenters and tradespeople prefer a wedge sole. This design features a continuous, solid sole from toe to heel without a separate, defined heel block.

This flat surface area disperses your body weight more evenly across the entire foot, reducing pressure points and significantly decreasing foot fatigue.

Absorbing the Impact: Cushioning

Constant walking and standing on hard surfaces sends shock up through your feet, knees, and back. A boot without proper cushioning will wear you down over the day.

A quality cushioned insole is essential for shock absorption. It acts as a buffer, making long hours of standing far more manageable.

The Importance of a Secure Fit

A boot should feel snug and secure without being tight. A proper fit, usually achieved with a lace-up design, prevents your foot from sliding inside.

This stops blisters from forming and ensures all the boot's safety and support features function as intended.

Understanding the Trade-offs

No single boot is perfect for every single task. You must weigh the pros and cons of certain features based on your typical workday.

Wedge Sole vs. Defined Heel

The wedge sole is superior for comfort when standing on flat surfaces like concrete floors or subflooring. However, a defined heel can provide a more secure purchase when climbing ladders, as the heel can lock onto rungs.

Waterproofing vs. Breathability

A fully waterproof boot is essential for working in consistently wet or muddy conditions. The trade-off is often a lack of breathability, which can lead to hot, sweaty feet during indoor or dry-weather work.

For mixed conditions, a water-resistant boot often provides a better balance, repelling moisture while still allowing your feet to breathe.

Making the Right Choice for Your Work

Select your boots based on the demands of your specific job.

- If your primary focus is maximum safety on a heavy construction site: Prioritize a certified steel toe, a puncture-resistant sole, and high ankle support.

- If your primary focus is all-day comfort for finish work or shop use: A wedge sole boot with excellent cushioning is your best investment to combat fatigue.

- If you frequently work in mixed indoor and outdoor conditions: Look for a boot that balances water resistance with breathability to keep your feet dry and comfortable.

Ultimately, view your work boots as an essential piece of personal equipment that directly impacts your safety, endurance, and the quality of your craft.

Summary Table:

| Feature | Why It's Important for Carpenters |

|---|---|

| Safety Toe (Steel/Composite) | Protects feet from heavy falling objects and compression. |

| Puncture-Resistant Sole | Shields feet from nails and sharp debris on the ground. |

| Slip-Resistant Outsole | Provides traction on dust, wood, and wet surfaces to prevent falls. |

| Ankle Support | Offers stability on ladders, scaffolding, and uneven surfaces. |

| Wedge Sole | Distributes weight evenly to reduce foot fatigue during long hours. |

| Cushioned Insole | Absorbs shock from standing and walking on hard surfaces. |

Ready to Equip Your Team with Superior Work Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and comfortable work boots tailored for the demands of carpentry. We provide the exact combination of safety features and all-day comfort your workforce needs.

We are the ideal partner for:

- Distributors & Brand Owners: Looking for reliable, high-volume production of custom or private-label footwear.

- Bulk Clients: Needing to outfit large crews with consistent, high-quality safety boots.

Our production capabilities encompass all types of safety shoes and boots. Let's discuss how we can support your business.

Contact us today for a consultation and quote!

Visual Guide

Related Products

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium KPU Injection Athletic Style Safety Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- Why is Production Capacity (Mcap) a core parameter in safety shoe contracts? Optimize Supply and Mitigate Risk

- Why is the use of steel-toe safety footwear critical during the maintenance of sugar factory press chains? Protect Your Team

- What are the primary safety functions of safety boots with steel-toe designs? Essential Protection for Industry

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management