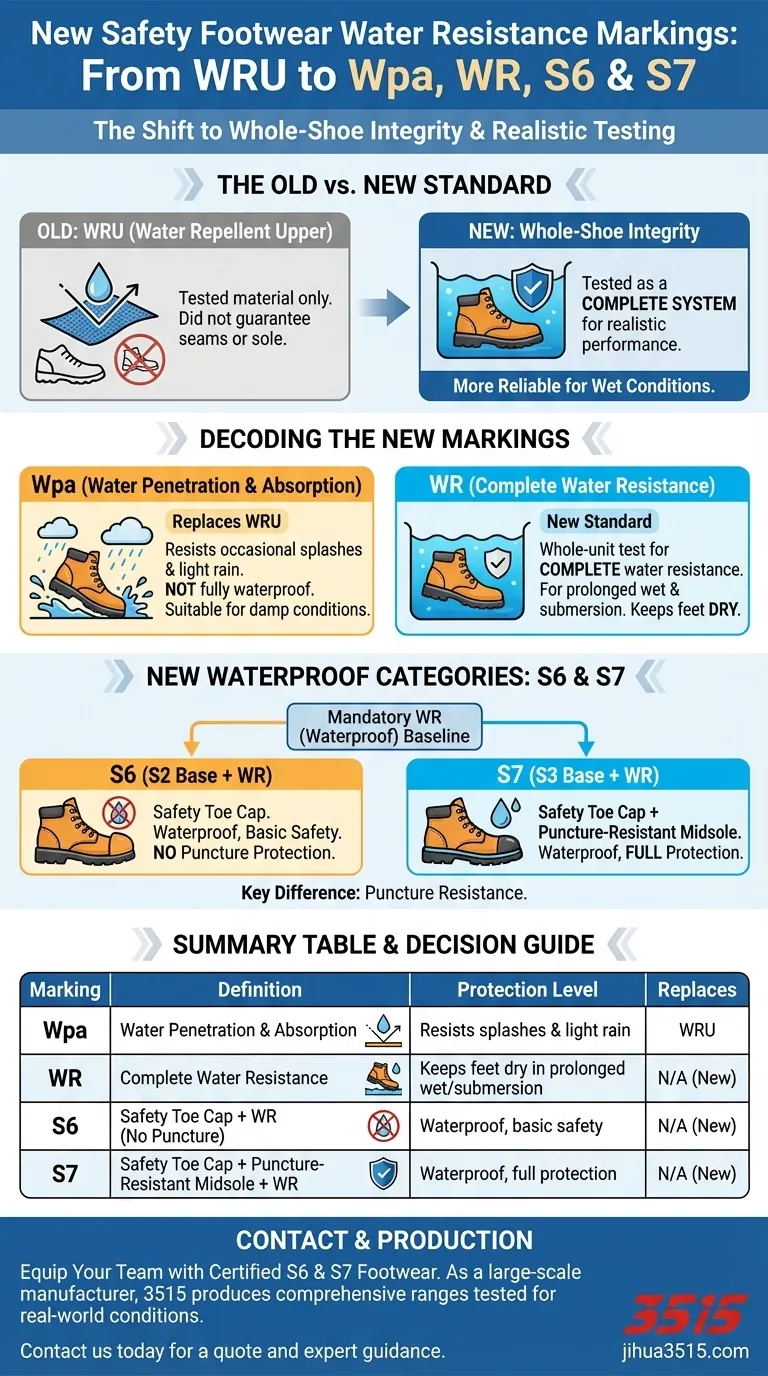

In the updated safety footwear standard, the previous WRU marking has been replaced by two more specific and rigorous classifications. These are Wpa (water penetration and absorption) and WR (complete water resistance), which now form the basis for the entirely new waterproof safety categories of S6 and S7.

The most critical change is the shift from testing only the upper material for water repellency to testing the entire shoe as a complete system. This provides a far more realistic and reliable measure of how footwear will actually perform in wet working conditions.

From Component Testing to Whole-Shoe Integrity

The fundamental update in the standard reflects a move towards more practical, real-world performance metrics. It acknowledges that a shoe's ability to keep water out depends on its overall construction, not just the material on top.

The Old Standard: WRU

The former WRU (Water Repellent Upper) marking only certified that the upper material of the footwear had been tested and met a standard for water resistance. This did not guarantee the seams or sole construction would prevent water ingress.

The New Standard: A Two-Tiered System

The new standard replaces this single, often misleading, marking with a more precise two-level system. This allows for a clearer distinction between water-resistant and fully waterproof footwear.

Decoding the New Water Resistance Markings

Understanding the two new markings is essential for selecting the correct footwear. They represent distinct levels of protection for different environments.

Wpa: Water Penetration and Absorption

The Wpa marking is the direct successor to WRU. It indicates that the footwear provides a good level of resistance to water getting through the upper.

It's designed for conditions where workers face occasional splashes or light rain, but not prolonged exposure or immersion.

WR: Complete Water Resistance

The WR marking signifies a much higher level of protection. Footwear with this rating has been tested as a whole unit to ensure it is completely waterproof.

This is the standard to look for when the user's feet must remain dry in consistently wet environments or during submersion.

Introducing the New Waterproof Categories: S6 and S7

The introduction of the WR marking created the need for new top-tier safety categories that have complete water resistance as a baseline requirement.

What Defines S6 and S7?

Both S6 and S7 categories begin with the core requirements of the S2 and S3 standards, respectively, but add the WR (waterproof) marking as a mandatory feature.

The Key Difference: Puncture Resistance

The distinction between them is simple and aligns with the previous standards.

- S6 footwear is built on an S2 base, meaning it has a safety toe cap but no puncture-resistant midsole.

- S7 footwear is built on an S3 base, meaning it includes both a safety toe cap and a puncture-resistant midsole.

Understanding the Trade-offs and Implications

This new system provides clarity but requires careful selection. A misunderstanding between Wpa and WR can lead to inadequate protection.

Wpa is Not Fully Waterproof

It is critical to remember that Wpa signifies water resistance, not a waterproof guarantee. It is suitable for damp conditions, but not for standing water or heavy, persistent rain.

WR Guarantees a Dry Foot

For roles where keeping feet dry is a non-negotiable safety or comfort requirement, only footwear marked with WR, S6, or S7 will suffice.

A Broader Shift to Realistic Testing

This change is part of a larger update to the standard. For example, the old slip-resistance tests (SRA, SRB) have also been updated to a single SR marking that uses a more realistic test method, simulating a natural walking motion. This shows the standard's overall move toward more practical and reliable safety ratings.

Making the Right Choice for Your Environment

Use this guide to select footwear that provides the precise level of protection required for your specific operational needs.

- If your primary focus is protection from occasional splashes or light rain: Look for footwear marked with

Wpa. - If your primary focus is keeping feet completely dry in prolonged wet conditions: You must select footwear marked

WR, which will fall into the newS6orS7categories. - If you need full water resistance and protection from sole puncture: Your definitive choice is footwear rated

S7.

By understanding these new, more practical ratings, you can confidently select the exact level of water protection your team requires.

Summary Table:

| Marking | Definition | Protection Level | Replaces |

|---|---|---|---|

| Wpa | Water Penetration and Absorption | Resists splashes and light rain | WRU |

| WR | Complete Water Resistance | Keeps feet dry in prolonged wet conditions or submersion | N/A (New) |

| S6 | Safety Toe Cap + WR (No Puncture Protection) | Waterproof, basic safety | N/A (New Category) |

| S7 | Safety Toe Cap + Puncture-Resistant Midsole + WR | Waterproof, full protection | N/A (New Category) |

Ensure your team has the right waterproof protection. As a large-scale manufacturer, 3515 produces a comprehensive range of certified S6 and S7 safety footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure you get durable, compliant footwear tested for real-world conditions. Contact us today for a quote and expert guidance.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene