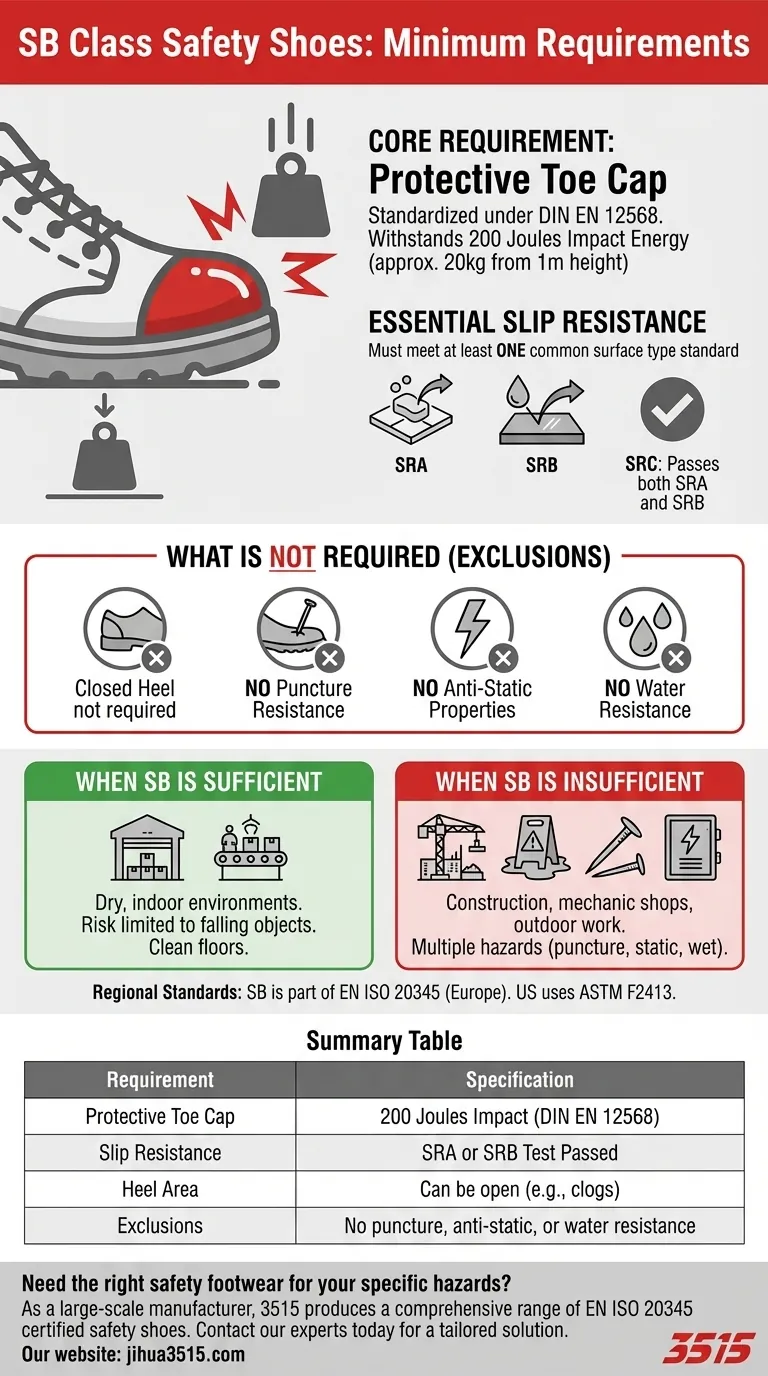

To be classified as SB (Safety Basic), a safety shoe must meet two fundamental requirements: it must have a protective toe cap capable of withstanding 200 joules of impact, and it must offer a basic level of slip resistance on at least one common surface type. All other protective features are optional for this baseline classification, and the heel area may even be open.

The SB rating represents the absolute minimum standard for safety footwear under European norms. It is designed solely for low-risk environments where the only significant hazard is the risk of impact to the toes from falling objects.

Deconstructing the SB Standard

The SB classification is the foundation upon which all higher safety shoe ratings are built. Understanding its components—and what it lacks—is crucial for assessing its suitability for your specific work environment.

The Core Requirement: The Protective Toe Cap

The non-negotiable feature of any SB-rated shoe is its reinforced toe cap. This component is certified to withstand a significant impact force.

This protection is standardized under DIN EN 12568, ensuring the toe cap can resist an impact energy of 200 joules. This is roughly equivalent to a 20 kg (44 lb) weight being dropped from a height of one meter.

Essential Slip Resistance

While the toe cap addresses impact, SB shoes must also provide a minimum level of grip to prevent slips and falls.

The footwear will be tested and certified with one of the following codes:

- SRA: Tested for slip resistance on ceramic tile floors with a soap solution.

- SRB: Tested for slip resistance on steel floors with glycerol.

- SRC: Passed both SRA and SRB tests, offering the highest level of slip resistance.

What Is Notably Absent in the SB Standard

The "basic" nature of the SB rating means it lacks many protections required for more hazardous jobs. An SB shoe is not required to have:

- A closed heel: Clog-style safety footwear can be SB-rated.

- Puncture resistance: The sole offers no protection from nails or other sharp objects.

- Anti-static properties: It does not protect against the buildup of static electricity.

- Water resistance: There are no requirements for keeping your feet dry.

Understanding the Trade-offs of Basic Protection

Choosing an SB-rated shoe involves a clear trade-off: you gain basic, certified toe protection in what can be a lighter and more open shoe, but you sacrifice protection against a wide range of other common workplace hazards.

When SB is Sufficient

An SB-rated shoe is appropriate for dry, indoor environments where the risk is almost exclusively limited to something falling on your feet. Think of certain warehousing roles, light assembly lines, or areas where heavy items are moved but the floor is clean and free of sharp debris.

When SB is Critically Insufficient

This basic rating is entirely unsuitable for most construction sites, mechanic shops, outdoor work, or any environment with multiple hazards. If your workplace involves nails, screws, wet surfaces, or risks of static discharge or electrical shock, you must choose a higher-rated shoe.

A Note on Regional Standards

It's important to recognize that SB is part of the European EN ISO 20345 standard. In the United States, workplace safety footwear is governed by ASTM F2413. While the goals are similar, the specific requirements and testing methods differ. Always ensure your footwear complies with the mandatory standards for your specific region and worksite.

Making the Right Choice for Your Hazard

Selecting safety footwear isn't about finding the minimum acceptable option; it's about accurately matching the protection to the real-world risks you face.

- If your primary focus is minimal toe protection in a dry, clean environment: An SB-rated shoe meets this baseline need.

- If your primary focus is protection from nails or sharp objects underfoot: You must upgrade to a rating that includes puncture resistance, such as S1P or S3.

- If your primary focus is working in wet conditions or outdoors: You need a shoe with water-resistant properties, found in ratings S2 and above.

- If your primary focus is working around electronics or flammable materials: You need footwear with anti-static properties, a feature that begins with the S1 rating.

Ultimately, your safety depends on a clear understanding of your environment's specific hazards.

Summary Table:

| Requirement | Specification |

|---|---|

| Protective Toe Cap | Must withstand 200 joules of impact (DIN EN 12568) |

| Slip Resistance | Must pass SRA (ceramic tile/soap) or SRB (steel/glycerol) test |

| Heel Area | Can be open (e.g., clogs) |

| Exclusions | No puncture resistance, anti-static, or water resistance required |

Need the right safety footwear for your specific hazards?

As a large-scale manufacturer, 3515 produces a comprehensive range of EN ISO 20345 certified safety shoes and boots for distributors, brand owners, and bulk clients. Whether you need basic SB-rated models or higher-level protection (S1, S3, etc.), our production capabilities ensure quality, compliance, and volume.

Contact our experts today for a tailored solution that protects your workforce.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

People Also Ask

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- Do snake bite boots work? Your Ultimate Guide to Effective Snake Bite Protection