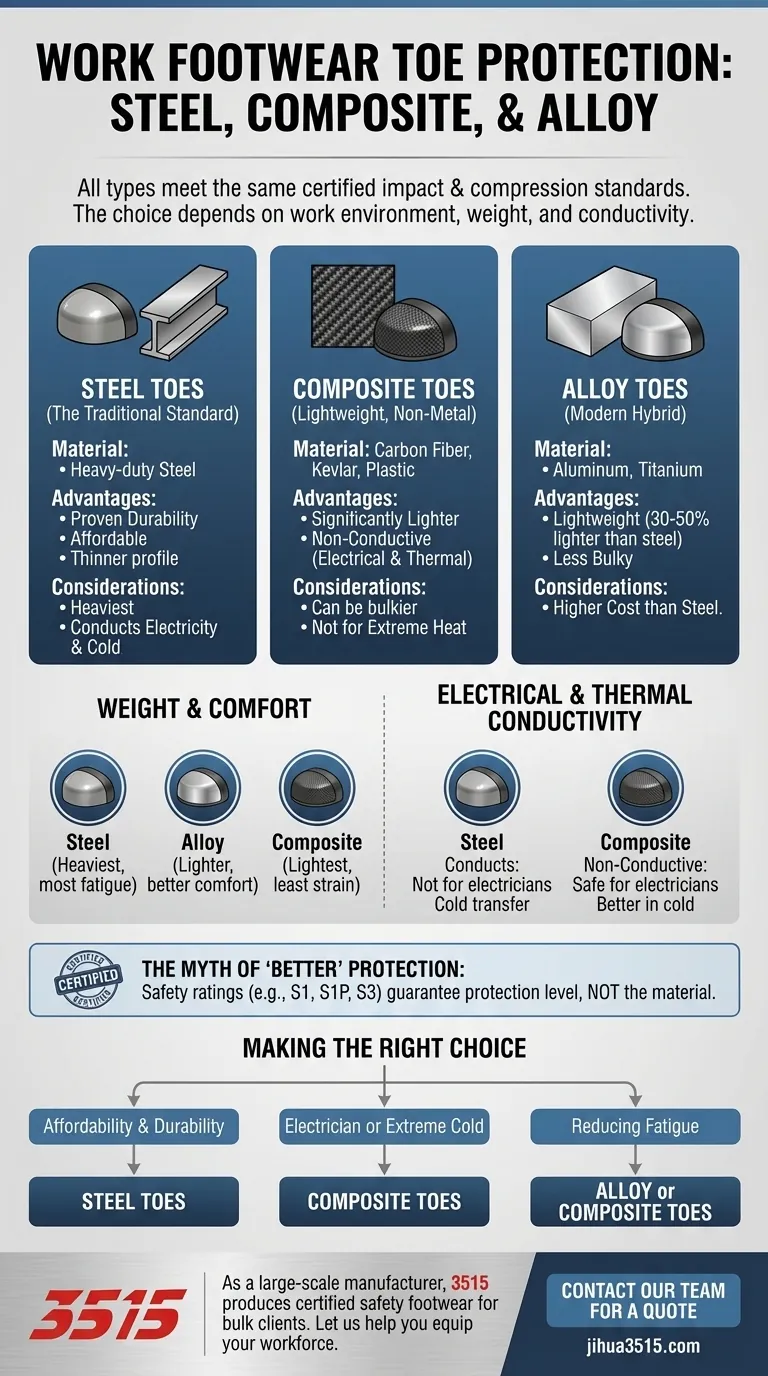

The primary types of protective toe caps in work footwear are steel, composite, and alloy. Each is engineered to provide a certified level of protection against impact and compression from falling objects, but they achieve this with different materials that carry distinct advantages and disadvantages.

The choice between steel, composite, or alloy toes is not about which is "stronger"—all must meet the same safety standards. The decision hinges on secondary factors like weight, conductivity, and cost, which you must match to your specific work environment and daily tasks.

A Breakdown of the Core Safety Toe Types

Understanding the material composition of each safety toe is the first step in selecting the right boot. Each one represents a different balance of properties.

Steel Toes: The Traditional Standard

Steel is the original material for safety toes and remains the industry benchmark. These toe caps are made from heavy-duty steel, providing robust and reliable protection.

Because of its strength, the steel cap can be made relatively thin, sometimes resulting in a less bulky boot profile compared to composite options.

Composite Toes: The Lightweight, Non-Metal Option

Composite toes are made from non-metal materials like carbon fiber, fiberglass, plastic, or Kevlar. Their primary advantage is being significantly lighter than steel.

This non-metallic construction means they do not conduct electricity, making them the only suitable choice for electricians or those working in high-voltage environments. They also don't conduct cold, offering better comfort in low-temperature conditions.

Alloy Toes: The Modern Hybrid

Alloy toes are crafted from lightweight metals such as aluminum or titanium. They provide the same level of impact resistance as steel but at a noticeably lower weight.

These toe caps are often seen as a middle ground, offering a lighter alternative to steel without being as bulky as some composite options can be.

Understanding the Trade-offs

The "best" safety toe is entirely dependent on your job's specific demands. The material itself is less about the level of protection and more about the features that support your work.

Weight and Comfort

The most significant difference felt day-to-day is weight. Steel toes are the heaviest option, which can lead to fatigue over long shifts.

Alloy toes are generally 30-50% lighter than steel, offering a significant improvement in comfort. Composite toes are the lightest of all, placing the least strain on your feet.

Electrical and Thermal Conductivity

This is a critical safety consideration. As a metal, steel conducts electricity and is not suitable for electricians.

Composite materials are non-conductive, making them essential for anyone working near live electrical currents. They also do not transfer cold, making them far more comfortable in freezing environments.

The Myth of "Better" Protection

A common misconception is that one material is inherently safer than another. In reality, any work boot sold with a safety rating (such as S1, S1P, or S3) must pass the same standardized impact and compression tests, regardless of whether the toe is steel, composite, or alloy.

The safety rating on the boot guarantees the level of protection, not the material inside the toe.

Making the Right Choice for Your Goal

Select your boot based on the primary demands of your workday, not just the material of the toe cap.

- If your primary focus is affordability and maximum durability: A steel toe boot often provides the best value and has a long-proven track record.

- If you are an electrician or work in extreme cold: A composite toe is the only safe and practical choice due to its non-conductive properties.

- If your primary focus is reducing fatigue over long shifts: An alloy or composite toe will provide certified protection at a significantly lower weight than steel.

Ultimately, choosing the right safety toe is about matching the material's unique properties to the specific risks and demands of your job.

Summary Table:

| Toe Type | Key Material | Primary Advantage | Key Consideration |

|---|---|---|---|

| Steel | Heavy-duty Steel | Proven Durability & Affordability | Heaviest Option; Conducts Electricity/Cold |

| Composite | Carbon Fiber, Kevlar, Plastic | Lightest Weight; Non-Conductive | Can Be Bulkier; Not for Extreme Heat |

| Alloy | Aluminum, Titanium | Lightweight Like Composite; Less Bulky | Higher Cost Than Steel |

Need the Perfect Safety Boot for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Whether you need durable steel toes, lightweight composites for electricians, or advanced alloy options, we have the production capabilities and expertise to meet your exact specifications.

Let us help you equip your workforce with the right protection.

Contact our team today for a quote to discuss your custom footwear needs.

Visual Guide

Related Products

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What are the technical advantages of industrial-grade slip-resistant safety shoes? Prevent Falls with Engineered Grip

- What specific protective functions do safety shoes offer during high-risk tasks? Master Safety on Structural Beams

- Why do operations involving heavy fruit bunches and 'gancu' require anti-smash and anti-puncture safety boots?

- How do professional safety shoes provide protection in automotive workshop environments? Essential PPE for Workshop Safety

- Why is specialized personal protective equipment required for specific industries? Enhancing Safety in Heavy Industry