A cowboy boot comprises several distinct structural components designed for durability and equestrian safety, primarily divided into the upper assembly and the lower sole construction. The key anatomical parts are the shaft (the leg covering), the vamp (the foot covering), the counter (internal heel support), and the sole assembly, which are fused together using a welt.

Understanding the anatomy of a boot is not just about vocabulary; it is about recognizing quality. A boot constructed with a true welt and a leather heel counter can be rebuilt and worn for decades, whereas glued alternatives are disposable.

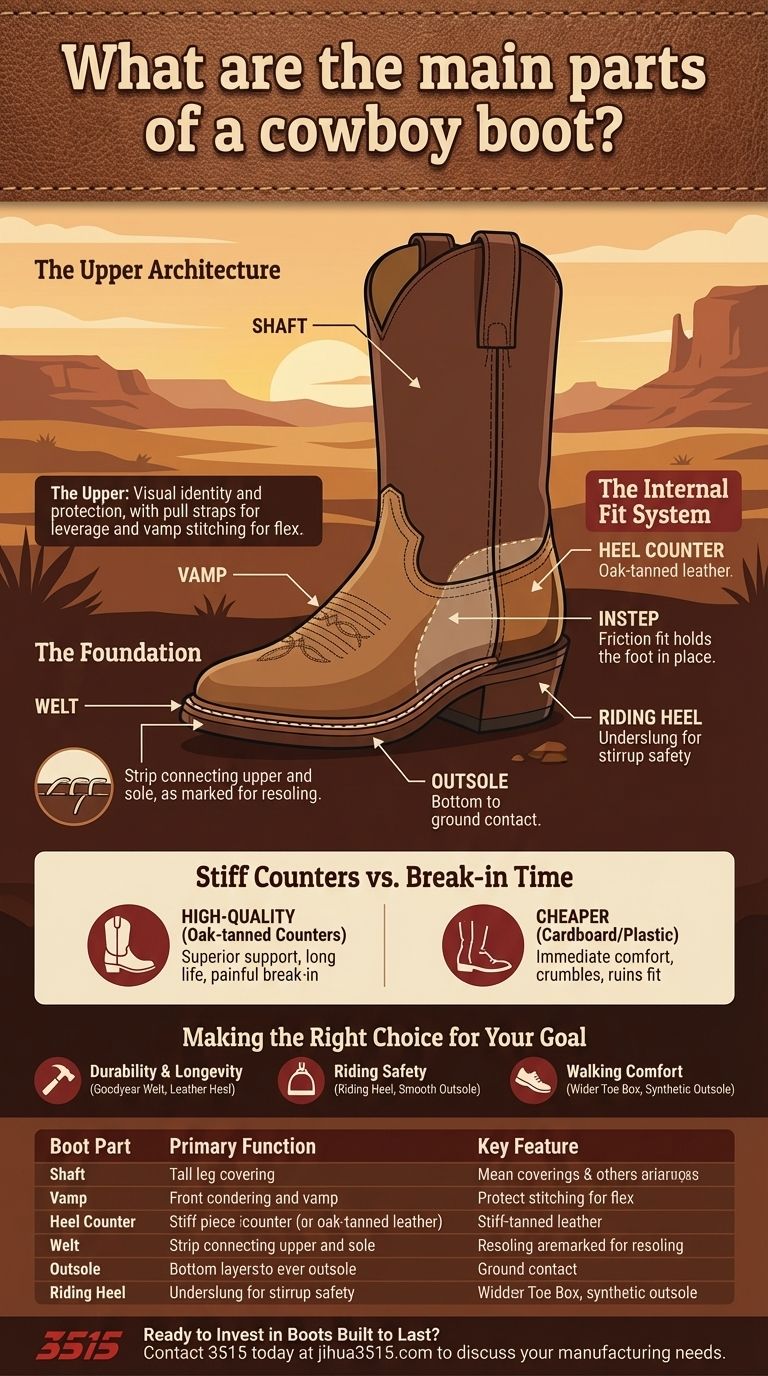

The Upper Architecture

The "Upper" refers to everything sitting above the sole. This is the visual identity of the boot, but its design is rooted in protection.

The Shaft and Pull Straps

The shaft is the tall tube of leather that wraps around the lower leg. Its original function was to protect the rider's legs from brush, thorns, and chafing against the saddle.

Attached to the top of the shaft are the pull straps (or tugs). Because cowboy boots lack laces, these reinforced loops are mechanically essential for providing the leverage needed to pull the boot onto the foot.

The Vamp

The vamp is the front part of the boot that covers the top of the foot and toes. It acts as the shield for the foot and is the area most prone to creasing and flexing during walking.

This section usually features decorative stitching, known as the "wrinkle" or "flower." While aesthetic today, this stitching originally helped the leather flex comfortably without cracking.

The Internal Fit System

Beneath the leather exterior lies the engineering that determines how the boot fits and performs.

The Instep and Tongue area

The instep is the arched area on top of the foot where the vamp meets the shaft.

Unlike lace-up boots, cowboy boots rely on a "friction fit" at the instep to hold the foot in place. The internal form (the last) is designed with an extended instep and narrowed shank to ensure the foot snaps securely into the bottom of the boot.

The Heel Counter

The counter is a stiff piece of material (ideally oak-tanned leather) sandwiched inside the heel of the boot.

Cowboy boots are wider at the top of the heel than standard shoes to accommodate this stiff counter, which is stitched into place. This component cups the heel bone, preventing the foot from sliding sideways or slipping up and down excessively.

The Foundation

The bottom assembly is built to withstand ground contact and interaction with a stirrup.

The Welt

The welt is a strip of leather that serves as the bridge between the upper leather and the sole.

This is a hallmark of high-quality construction. By stitching the upper to the welt, and then the welt to the sole, the boot becomes water-resistant and, crucially, resoleable.

The Outsole

The outsole is the bottom-most layer that makes direct contact with the ground.

While often made of leather for tradition and breathability, the outsole takes the brunt of the wear. When this layer wears through, a cobbler can replace it without damaging the rest of the boot, provided the welt is intact.

The Heel

The exterior heel is distinct from the internal counter. Traditionally, it is underslung (angled forward).

This specific angle is a safety feature designed to keep the boot secure in a stirrup while riding, preventing the foot from sliding all the way through.

Understanding the Trade-offs

When evaluating boot construction, you must balance immediate comfort against long-term durability.

Stiff Counters vs. Break-in Time

High-quality boots utilize stiff, oak-tanned counters. These provide superior support and prevent the boot from collapsing over time, but they require a painful "break-in" period to mold to your specific heel shape.

Cheaper boots use cardboard or plastic counters. These feel comfortable immediately but will eventually crumble or lose their shape, ruining the fit of the boot.

Leather Soles vs. Longevity

Traditional leather outsoles breathe well and glide easily out of stirrups. However, they possess poor traction on modern surfaces like concrete and wear down relatively quickly compared to rubber.

Making the Right Choice for Your Goal

To select the right boot, you must prioritize the components that align with your daily use.

- If your primary focus is Durability and Longevity: Prioritize a boot with a Goodyear welt and a stacked leather heel, as these allow for repeated resoling.

- If your primary focus is Riding Safety: Ensure the boot features a properly angled riding heel and a smooth outsole to prevent getting hung up in the stirrup.

- If your primary focus is Walking Comfort: Look for a boot with a slightly wider toe box and perhaps a synthetic outsole for better shock absorption on pavement.

Your boots are an investment in your footing; choose the construction that supports where you stand.

Summary Table:

| Boot Part | Primary Function | Key Feature |

|---|---|---|

| Shaft | Protects the lower leg from brush and saddle chafing. | Tall leather tube with pull straps for easy on/off. |

| Vamp | Covers the top of the foot and toes; flexes during walking. | Often features decorative stitching to prevent cracking. |

| Heel Counter | Internally supports the heel to prevent slippage. | Stiff, oak-tanned leather for long-term shape retention. |

| Welt | Connects the upper to the sole, allowing for resoling. | Sign of high-quality, durable construction. |

| Outsole | The ground-contact layer; determines traction and wear. | Leather for tradition, rubber for modern comfort. |

| Riding Heel | Angled design to secure the foot in a stirrup. | Underslung shape for equestrian safety. |

Ready to Invest in Boots Built to Last?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including expertly crafted cowboy boots designed with the quality components detailed above.

We ensure every pair meets high standards of durability, safety, and comfort. Partner with us to offer your customers boots that are not just worn, but invested in.

Contact 3515 today to discuss your manufacturing needs and discover how we can support your business with reliable, high-quality footwear.

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What are the key components of an operator's loadout? A Guide to Mission-Ready Gear Systems

- What are the benefits of custom wheel leather welts and rands in western boots? Discover Superior Craftsmanship & Durability

- How do big data analytics tools contribute to SDGs in footwear supply chains? Drive Sustainability Through Precision

- What are the characteristics and considerations of using manual tools in footwear production? Precision vs. Ergonomics

- What are the core material advantages of using TPU in auxetic shoe soles? Boost Durability & Geometric Precision

- What role do auxiliary materials play in leather shoe product mix optimization? Maximize Profit & Stability

- What is the difference between first-layer and second-layer natural leather? Choose the Right Material for Your Footwear

- How do new dyeing technologies contribute to clean production goals? Transforming Footwear with Sustainable Innovation