In short, the primary materials used in half-boots are leather, rubber, and synthetic textiles. These are not used interchangeably but are selected and combined based on the boot's intended purpose, whether for rugged work, hiking, or casual wear. Each material offers a distinct profile of durability, water resistance, breathability, and weight.

The construction of a half-boot is a deliberate engineering choice, not just a matter of style. The specific combination of materials in the upper, lining, and sole directly dictates its performance, comfort, and lifespan.

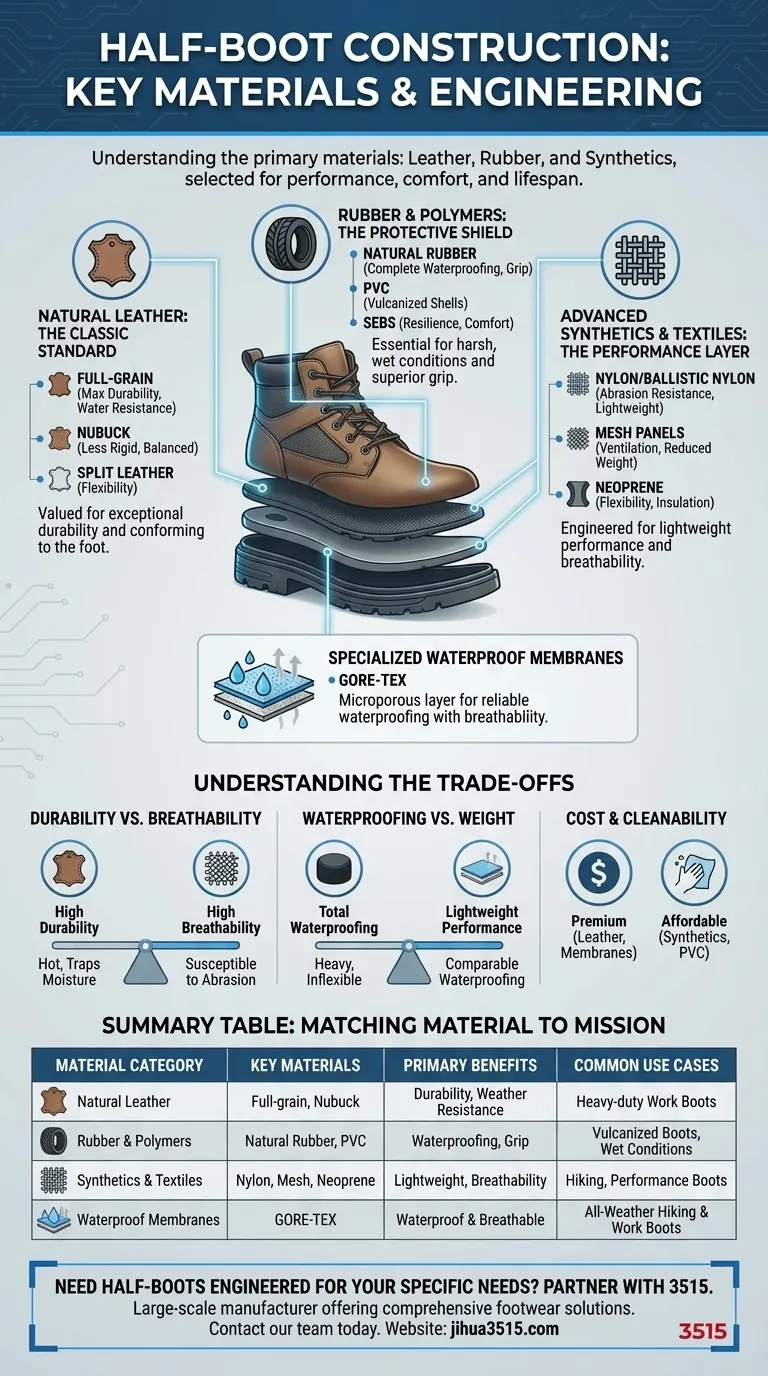

Deconstructing the Half-Boot: Key Material Categories

A boot is a system of materials working together. The upper provides structure and protection, while internal layers and membranes manage moisture and comfort.

Natural Leather: The Classic Standard

Leather is a traditional choice valued for its exceptional durability and ability to conform to the wearer's foot over time. Different types are used for different effects.

Full-grain leather is the highest quality, offering maximum strength and water resistance. Nubuck and split leather are less rigid alternatives that provide a balance of durability and flexibility.

Rubber and Polymers: The Protective Shield

For boots designed to face harsh, wet conditions, rubber and similar synthetic compounds are essential.

Natural rubber and PVC are commonly used for the entire boot shell in vulcanized footwear, offering complete waterproofing and excellent grip. Synthetic rubbers like SEBS are also chosen for their resilience and comfort.

Advanced Synthetics and Textiles: The Performance Layer

Modern boots frequently rely on engineered textiles to achieve specific performance goals that natural materials cannot easily meet.

Nylon, especially ballistic nylon, provides outstanding abrasion resistance without the weight of leather. Mesh panels are integrated to dramatically increase ventilation and reduce overall weight, crucial for walking or hiking boots. Neoprene offers flexibility and insulation, often found in combination with rubber.

Specialized Waterproof Membranes

To solve the problem of water getting in while letting sweat vapor out, specialized membranes are laminated inside the upper.

The most well-known example is GORE-TEX. This microporous material acts as a critical inner layer that provides reliable waterproofing while maintaining a high degree of breathability.

Understanding the Trade-offs: Why Material Choice Matters

Selecting a boot involves navigating a series of trade-offs. The ideal material for one environment is often a poor choice for another.

The Durability vs. Breathability Dilemma

There is often an inverse relationship between a material's toughness and its ability to breathe.

A thick, full-grain leather upper is exceptionally durable but can become hot and trap moisture. Conversely, a boot with extensive mesh panels will be highly breathable but more susceptible to abrasion and tears.

The Waterproofing vs. Weight Equation

Achieving total water protection can add significant weight.

A solid rubber boot is impervious to water but is also heavy and inflexible. A lighter boot using synthetic textiles and a GORE-TEX membrane can offer comparable waterproofing with better breathability and far less weight, though often at a higher price.

Cost and Cleanability Factors

Material choice directly impacts the final price and required upkeep of the boot.

High-grade leathers and technical membranes are premium-priced components. Synthetics and PVC are generally more affordable and significantly easier to clean, requiring little more than a simple wipe-down.

Matching the Material to Your Mission

Your final choice should be guided entirely by the intended use of the boot.

- If your primary focus is maximum durability and weather protection for heavy work: Seek boots constructed from thick full-grain leather or vulcanized natural rubber.

- If your primary focus is lightweight performance and breathability for hiking: Look for uppers that combine synthetic materials like nylon and mesh with a waterproof membrane.

- If your primary focus is versatile, all-around comfort for daily wear: A hybrid construction using split leather and textile panels offers an excellent balance of support, flexibility, and breathability.

Understanding these core materials empowers you to see beyond marketing and select a boot truly engineered for your needs.

Summary Table:

| Material Category | Key Materials | Primary Benefits | Common Use Cases |

|---|---|---|---|

| Natural Leather | Full-grain, Nubuck | Durability, Weather Resistance | Heavy-duty Work Boots |

| Rubber & Polymers | Natural Rubber, PVC | Waterproofing, Grip | Vulcanized Boots, Wet Conditions |

| Synthetics & Textiles | Nylon, Mesh, Neoprene | Lightweight, Breathability | Hiking, Performance Boots |

| Waterproof Membranes | GORE-TEX | Waterproof & Breathable | All-Weather Hiking & Work Boots |

Need Half-Boots Engineered for Your Specific Needs? Partner with 3515.

As a large-scale manufacturer, we produce a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, allowing us to expertly combine materials like leather, advanced synthetics, and waterproof membranes to create the perfect half-boot for your market and application.

Let's discuss your project: Contact our team today to get started.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene