At its core, a modern military boot is an engineered system built from four primary components. These are the upper, which covers the foot; the insole, which provides initial cushioning; the midsole, which delivers structure and shock absorption; and the outsole, which provides traction.

Understanding how these four parts function and interact is the key to selecting a boot that performs reliably under specific conditions, whether your priority is durability, comfort, or all-terrain stability.

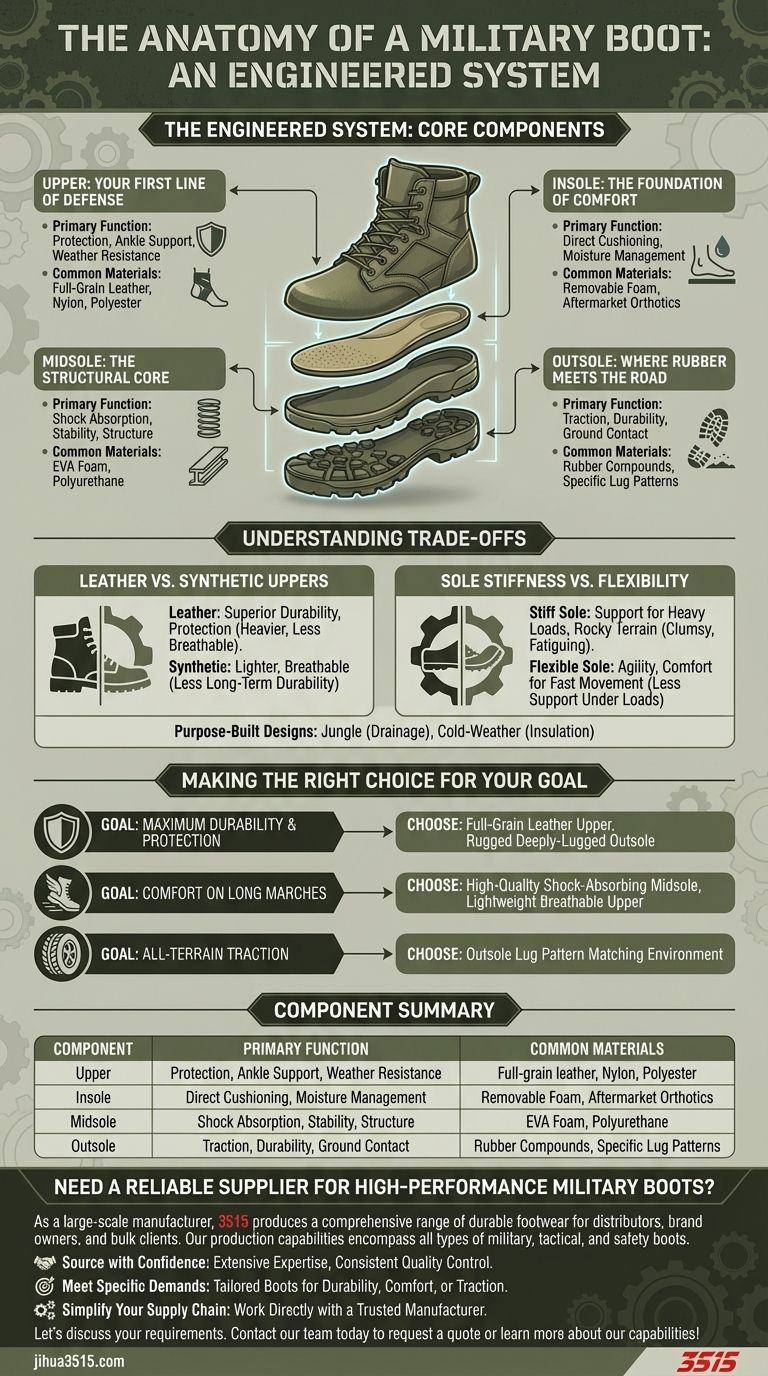

Deconstructing the Boot: The Four Core Components

A military boot is far more than simple footwear; it's a critical piece of equipment. Each of its main components is designed to fulfill a specific role, and their synergy determines the boot's overall performance.

The Upper: Your First Line of Defense

The upper is the entire part of the boot that covers the top and sides of your foot. Its primary job is to protect you from the elements, debris, and impacts while providing crucial ankle support.

Uppers are typically constructed from a combination of materials. Full-grain leather offers maximum durability and water resistance, while synthetic fabrics like nylon or polyester are incorporated to reduce weight and increase breathability.

The Insole: The Foundation of Comfort

The insole, or footbed, is the removable layer of material your foot rests on directly inside the boot. Its main purpose is to provide cushioning and manage moisture.

While factory insoles offer basic comfort, many users replace them with aftermarket options tailored to their specific arch type and cushioning needs.

The Midsole: The Structural Core

Sandwiched between the insole and the outsole, the midsole is the boot's unsung hero. This critical layer is responsible for absorbing shock, providing stability, and giving the boot its underlying structure.

The midsole's material composition (often EVA foam or polyurethane) dictates the boot's stiffness and how well it protects your joints from the repeated impact of walking or running on hard terrain.

The Outsole: Where Rubber Meets the Road

The outsole is the bottom-most layer of the boot that makes direct contact with the ground. It is engineered for two things: traction and durability.

The material is typically a durable rubber compound, and the design, known as the lug pattern, is configured to provide grip on specific surfaces like mud, rock, or pavement.

Understanding the Trade-offs

No single boot is perfect for every mission. The materials and construction of each component involve a series of deliberate engineering trade-offs.

Leather vs. Synthetic Uppers

A boot with a predominantly leather upper will offer superior durability and protection but will be heavier and less breathable.

Conversely, a boot with more synthetic fabric will be lighter and more breathable, making it ideal for hot climates or high-mobility tasks, but it may offer less protection and long-term durability.

Sole Stiffness vs. Flexibility

A thick, rigid sole provides excellent support when carrying heavy loads or navigating uneven, rocky terrain. However, this stiffness can feel clumsy and fatiguing during long marches on flat ground or when running.

A more flexible sole enhances agility and comfort for faster movement on predictable surfaces but offers less protection and support under heavy loads.

Purpose-Built Designs

It's critical to recognize that components are chosen to match a boot's intended environment. A jungle boot will prioritize drainage and quick-drying materials, while a cold-weather boot will feature insulation in the upper and a sole compound that remains pliable in freezing temperatures.

Making the Right Choice for Your Goal

By understanding these components, you can analyze a boot based on your specific requirements.

- If your primary focus is maximum durability and protection: Look for a boot with a full-grain leather upper and a rugged, deeply-lugged outsole.

- If your primary focus is comfort on long marches: Prioritize a boot with a high-quality, shock-absorbing midsole and a lightweight, breathable upper.

- If your primary focus is all-terrain traction: Closely examine the outsole's lug pattern and material to ensure it matches the environments you'll face.

Ultimately, choosing the right boot means understanding it as a complete system and selecting the one whose components are best engineered for your mission.

Summary Table:

| Component | Primary Function | Common Materials |

|---|---|---|

| Upper | Protection, ankle support, weather resistance | Full-grain leather, nylon, polyester |

| Insole | Direct cushioning, moisture management | Removable foam, aftermarket orthotics |

| Midsole | Shock absorption, stability, structure | EVA foam, polyurethane |

| Outsole | Traction, durability, ground contact | Rubber compounds with specific lug patterns |

Need a reliable supplier for high-performance military boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of military, tactical, and safety boots, engineered with the precise balance of components for any mission or environment.

We help you:

- Source with Confidence: Benefit from our extensive manufacturing expertise and consistent quality control.

- Meet Specific Demands: Get boots tailored to your needs, whether for durability, comfort, or specialized traction.

- Simplify Your Supply Chain: Work directly with a trusted manufacturer for efficient, large-volume orders.

Let's discuss your specific requirements. Contact our team today to request a quote or learn more about our capabilities!

Visual Guide

Related Products

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- Durable High-Ankle Tactical Boots Wholesale Manufacturer for Custom & Bulk Orders

People Also Ask

- Why has Cordura remained relevant despite new fabrics? The Unbeatable Balance of Durability & Comfort

- What replaced jungle boots in the US military? The Shift to Tan Suede Combat Boots

- How can a shiny finish be achieved on military boots? A Step-by-Step Guide to a Mirror Shine

- How did combat boots transition from military use to popular culture? From Battlefield to Fashion Statement

- What are the key features of the new Army Jungle Combat Boot? A Breakdown for Hot & Wet Environments