The key safety standards for work boots in the United States are ASTM F2413 and ASTM F3445. These standards are established by the American Society for Testing and Materials (ASTM) and enforced by the Occupational Safety and Health Administration (OSHA). ASTM F2413 defines the minimum performance requirements for protective features like safety toes and electrical hazard resistance, while ASTM F3445 specifically rates footwear for slip resistance.

Understanding work boot safety isn't about memorizing codes; it's about matching the specific protections certified under ASTM standards to the real-world hazards you face on the job. The label inside the boot tells you exactly what dangers it is designed to mitigate.

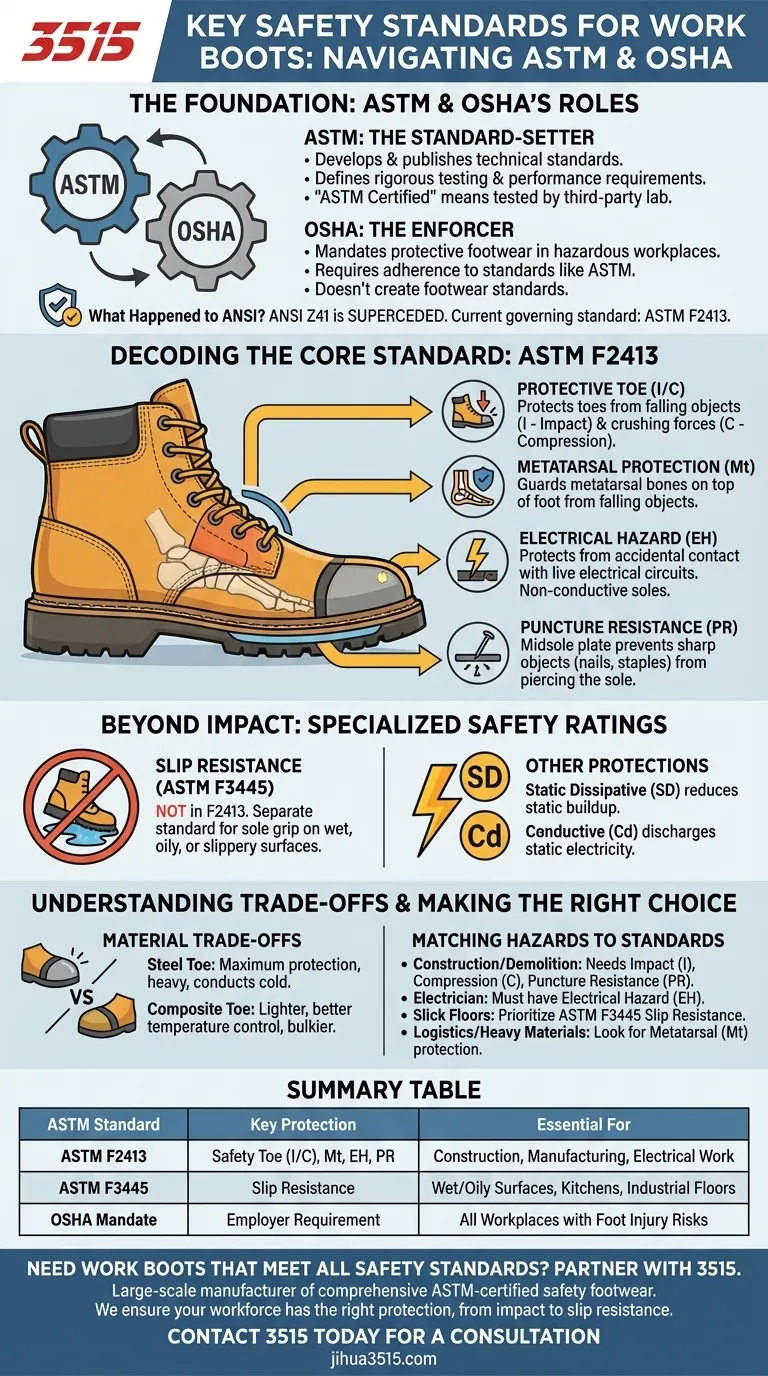

The Foundation: ASTM and OSHA's Roles Explained

To navigate safety standards, you must first understand the two key organizations involved: ASTM and OSHA. They have distinct but complementary roles.

ASTM: The Standard-Setter

ASTM International (American Society for Testing and Materials) is the organization that develops and publishes the technical standards. They define the rigorous testing methods and minimum performance requirements for safety footwear.

When a boot is "ASTM certified," it means a sample has been tested by a third-party lab and proven to meet these specific performance benchmarks.

OSHA: The Enforcer

OSHA (Occupational Safety and Health Administration) is the government agency responsible for ensuring safe workplace conditions. OSHA does not create the footwear standards themselves.

Instead, OSHA mandates that employers require workers to use protective footwear in any environment where there is a danger of foot injury. OSHA requires that this footwear meet the standards set by organizations like ASTM.

What Happened to ANSI?

You may still hear references to the American National Standards Institute (ANSI). While ANSI previously set the industry standard (ANSI Z41), it has been superseded.

The current, governing standard for protective footwear in the US is ASTM F2413.

Decoding the Core Standard: ASTM F2413

The ASTM F2413 standard is the cornerstone of protective footwear. A compliant boot will have a label indicating which specific sections of the standard it meets.

Protective Toe (I/C)

This is the most fundamental feature of a safety boot. It protects the toes from falling objects and crushing forces.

- Impact (I): The rating tests the boot's ability to protect the toe from a heavy object falling from a specific height.

- Compression (C): The rating tests the boot's ability to protect the toe from a heavy rolling object.

Metatarsal Protection (Mt)

This provides an added layer of defense for the delicate metatarsal bones on the top of your foot. It is critical for jobs where objects could drop directly onto the foot's instep.

Electrical Hazard (EH)

EH-rated boots are designed to protect the wearer from accidental contact with live electrical circuits. They are manufactured with non-conductive, shock-resistant soles and heels.

Puncture Resistance (PR)

This feature indicates a puncture-resistant plate has been built into the midsole of the boot. It is designed to protect the foot from being pierced by sharp objects from below, such as nails, staples, or scrap metal.

Beyond Impact: Specialized Safety Ratings

While ASTM F2413 covers the primary protective features, other standards address different but equally important hazards.

Slip Resistance (ASTM F3445)

Critically, slip resistance is not covered under the main F2413 standard. A separate standard, ASTM F3445, specifies the performance requirements for testing how well a boot's sole grips various wet, oily, or otherwise slippery surfaces.

Other Protections

The ASTM framework also includes standards for more specialized needs, such as Static Dissipative (SD) footwear to reduce the buildup of static electricity and Conductive (Cd) footwear to actively discharge it.

Understanding the Trade-offs and Pitfalls

Choosing the right boot involves more than just finding one that is "ASTM-certified." You must consider the specific combination of features.

Not All Safety Boots Are Equal

A boot can be ASTM-certified for its safety toe but offer no electrical hazard or puncture resistance. It is essential to read the specific ratings on the boot's tag to ensure it protects against your specific job site hazards.

Protection vs. Comfort

Different materials offer different benefits. A steel toe provides maximum protection but is heavy and conducts cold. A composite toe is lighter and better for temperature-variable environments but may be bulkier to achieve the same safety rating.

International Standards are Different

If you work outside the United States, you will encounter different standards. The primary standard in Canada is from the CSA (Canadian Standards Association), while Europe uses the EN ISO (European Norm) standard. These ratings are not interchangeable.

Making the Right Choice for Your Goal

Always start by identifying the primary hazards of your job, then find a boot with the corresponding certifications.

- If your primary focus is construction or demolition: You need boots with, at a minimum, Impact (I), Compression (C), and Puncture Resistance (PR) ratings.

- If your primary focus is working as an electrician: You must have boots with an Electrical Hazard (EH) rating to protect against shock.

- If your primary focus is working on slick floors (e.g., kitchens, manufacturing): Prioritize a high slip-resistance rating under ASTM F3445 alongside any other required protections.

- If your primary focus is logistics or moving heavy materials: Look for Metatarsal (Mt) protection in addition to a standard safety toe to guard against falling items.

Ultimately, the right safety boot is the one whose certified protections directly counter the specific hazards of your daily work.

Summary Table:

| ASTM Standard | Key Protection | Essential For |

|---|---|---|

| ASTM F2413 | Safety Toe (I/C), Metatarsal (Mt), Electrical Hazard (EH), Puncture Resistance (PR) | Construction, Manufacturing, Electrical Work |

| ASTM F3445 | Slip Resistance | Wet/Oily Surfaces, Kitchens, Industrial Floors |

| OSHA Mandate | Employer Requirement for Hazardous Environments | All Workplaces with Foot Injury Risks |

Need Work Boots That Meet All Safety Standards? Partner with 3515.

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and work shoes, engineered to meet or exceed ASTM F2413 and F3445 requirements.

We ensure your workforce has the right protection for their specific hazards—from impact-resistant toes to superior slip resistance. Let us help you source compliant, durable safety footwear that keeps your team safe and productive.

Contact 3515 today for a consultation and get the right safety solution for your business.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium KPU Injection Athletic Style Safety Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What is the primary function of industrial safety shoes in polymer recycling? Protect Against Machinery & Sharp Debris

- How does the slip resistance of industrial safety shoes protect workers during Genset maintenance? Prevent Oil Slips

- What protective functions do industrial safety shoes provide in petroleum environments? Secure Your Workers' Health

- What specific protective features are required for safety shoes in high-temperature rotary kiln maintenance areas?

- How do professional safety shoes protect the musculoskeletal system? Enhance Worker Ergonomics & Reduce Fatigue