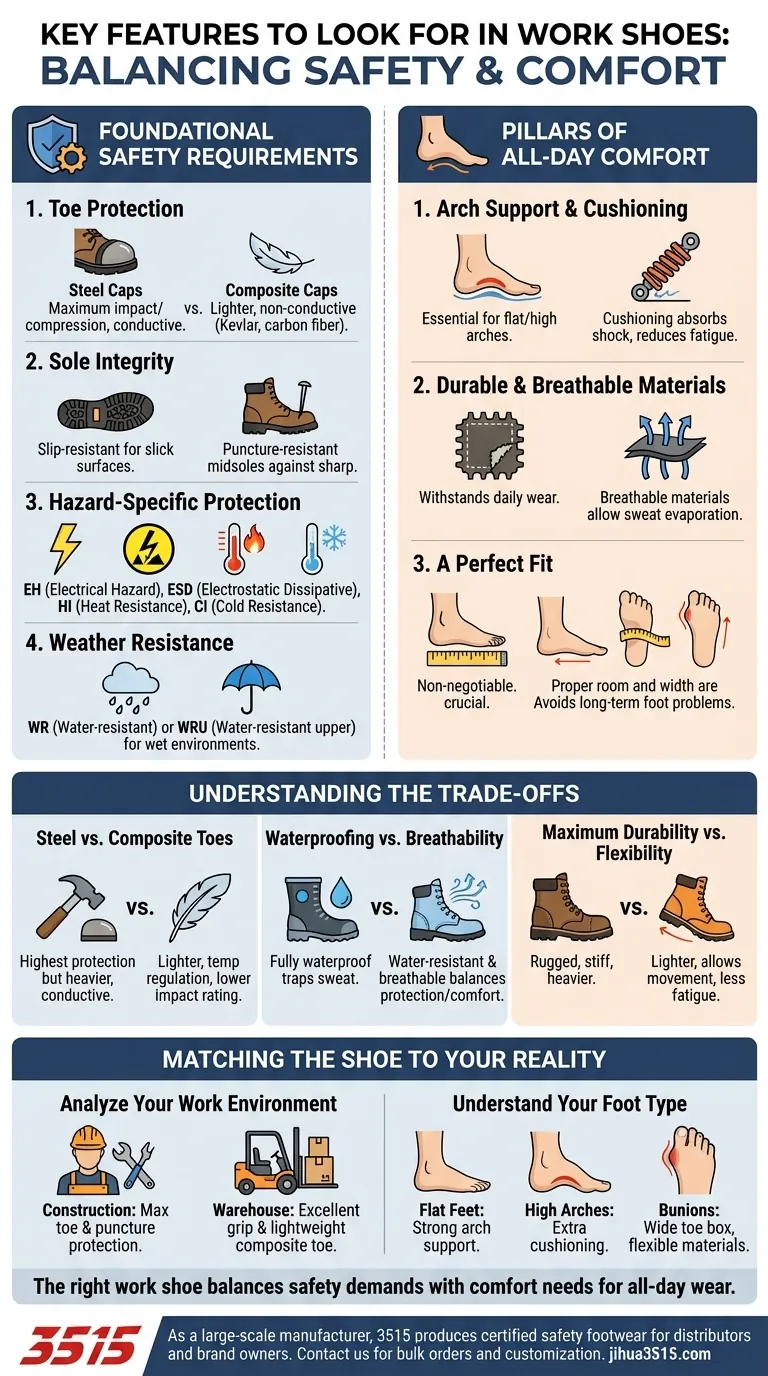

The most important features in work shoes fall into two critical categories: those that protect you from your work environment and those that protect you from the shoe itself. Key safety features include certified toe protection, puncture and slip-resistant soles, and specialized hazard resistance, while comfort is dictated by proper arch support, cushioning, and a correct fit that matches your specific foot type.

The best work shoe is not simply the one with the most safety features, but the one that correctly balances the non-negotiable safety demands of your job with the unique comfort requirements of your feet for all-day wear.

Deconstructing the Essential Features

Understanding the core components of a work shoe allows you to assess its suitability for your specific needs. We can separate these into foundational safety requirements and the pillars of long-term comfort.

Foundational Safety Requirements

Your primary concern is mitigating workplace hazards. Look for clear markings that certify the shoe's protective capabilities.

- Toe Protection: This is the most recognized feature. Steel caps offer maximum protection against impact and compression, while composite caps (made of materials like Kevlar, carbon fiber, or plastic) are lighter and don't conduct heat or cold.

- Sole Integrity: The sole is your interface with the ground. Look for slip-resistant properties, especially on slick surfaces. Puncture-resistant midsoles protect you from sharp objects like nails.

- Hazard-Specific Protection: Your job may have unique risks. Electrical Hazard (EH) shoes protect against open circuits, while Electrostatic Dissipative (ESD) shoes prevent static buildup. Temperature resistance is marked as HI for heat and CI for cold.

- Weather Resistance: For outdoor or wet environments, look for WR (water-resistant) or WRU (water-resistant upper) ratings to ensure your feet stay dry.

The Pillars of All-Day Comfort

Safety is paramount, but comfort is what allows you to perform your job effectively without pain or long-term foot problems.

- Arch Support & Cushioning: Proper support is crucial, especially for those with flat feet or high arches. Good cushioning absorbs shock from walking on hard surfaces, reducing fatigue in your feet, legs, and back.

- Durable and Breathable Materials: The shoe's upper should be made of durable materials that can withstand daily wear. However, these materials must also be breathable to allow sweat to evaporate, preventing discomfort and blisters.

- A Perfect Fit: This is non-negotiable. Work shoes should have enough room for your toes to move, and the width should be appropriate for your foot. A poor fit can affect your gait and cause significant discomfort.

Matching the Shoe to Your Reality

A feature is only valuable if it solves a problem you actually have. Before choosing, you must analyze your environment and your own body.

First, Analyze Your Work Environment

The demands of your job dictate your safety priorities.

A construction worker needs maximum toe protection and puncture-resistant soles. In contrast, a warehouse worker may prioritize excellent grip for slippery floors and a lighter composite toe for constant movement.

Second, Understand Your Foot Type

Generic shoes are built for generic feet. If you have a specific foot condition, you need specific features.

- Flat feet require shoes with strong, supportive arches to prevent over-pronation.

- High arches benefit from extra shock absorption and cushioning to handle the increased pressure on the ball and heel.

- Bunions demand a wide toe box and flexible upper materials to avoid painful pressure and irritation.

The Critical Rule: Safety Shoes Do Not "Break In"

Unlike casual footwear, the reinforced structure of a safety shoe will not stretch or conform to your foot over time.

An improper fit from day one will remain an improper fit forever. This can cause blisters, calluses, and even stress the shoe's protective components. Always try shoes on at the end of the day when your feet are slightly swollen, and wear the type of socks you use for work.

Understanding the Trade-offs

Choosing the perfect work shoe often involves balancing competing features. Being aware of these trade-offs helps you make a more informed decision.

Steel vs. Composite Toes

Steel offers the highest level of protection but is heavier and can be uncomfortable in extreme temperatures. Composite toes are lighter and better for temperature regulation but may not meet the highest impact ratings required for some jobs.

Waterproofing vs. Breathability

A fully waterproof boot (WR) is excellent for keeping water out, but it can also trap sweat inside. For less extreme conditions, a water-resistant upper (WRU) combined with breathable materials may offer a better balance of protection and comfort.

Maximum Durability vs. Flexibility

The most rugged, durable materials are often stiffer and heavier. This is ideal for stationary or low-movement jobs but can be fatiguing for workers who are constantly walking, bending, or climbing.

How to Apply This to Your Job

Focus on your primary daily challenge to narrow down the right features for you.

- If your primary focus is protection from heavy objects and sharp hazards: Prioritize a steel toe cap and a puncture-resistant sole plate above all else.

- If your primary focus is all-day comfort while walking on hard concrete: Prioritize superior cushioning, strong arch support, and a lightweight composite toe.

- If your primary focus is preventing slips in wet or oily conditions: Ensure your shoe has a top-tier slip-resistant outsole designed specifically for those surfaces.

- If your primary focus is adapting to extreme temperatures: Choose composite toes and look for specific insulation ratings like CI (cold) or HI (heat).

Ultimately, the right work shoe is a critical piece of personal protective equipment that empowers you to do your job safely and without pain.

Summary Table:

| Feature Category | Key Considerations |

|---|---|

| Safety | Toe protection (steel/composite), slip/puncture resistance, hazard ratings (EH, ESD), weather resistance (WR/WRU) |

| Comfort | Arch support, cushioning, breathable materials, correct fit for foot type (flat/high arches, bunions) |

| Environment | Match shoe to job demands: construction (max protection), warehouse (lightweight grip), extreme temperatures |

Ready to Equip Your Workforce with Superior Safety Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, comfortable, and certified work shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear tailored to your specific industry needs—from steel-toe boots for construction to lightweight, slip-resistant shoes for logistics.

We help you:

- Source high-quality, reliable footwear that meets international safety standards.

- Customize products to fit your brand and your customers' unique demands.

- Ensure consistent supply and competitive pricing for bulk orders.

Let's discuss your requirements and how we can support your business. Contact our team today for a consultation!

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Suede Metatarsal Guard Safety Boots Work Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- How do Intelligent Tags in Safety Shoes ensure compliance? Revolutionize Workplace Safety with Real-Time PPE Verification

- What is the purpose of safety footwear standards like EN ISO 20345? Ensure Worker Safety with Certified Protection

- How can the monitoring of safety shoe usage be utilized as a KPI? Drive Compliance & Strategic Safety Management

- What role does professional footwear play in occupational health? Engineering Controls for Workplace Safety

- Why is compliance with safety standards such as PN EN ISO 20347:2012 critical? Ensure Certified Workplace Protection

- What are the technical advantages of using puncture-resistant composite midsoles in safety footwear? | Lightweight Power

- In what way does the use of professional industrial footwear assist in preventing ergonomic injuries? Protect Your Team

- What are the basic ratings of security guard safety boots? A Guide to EN ISO 20345 Standards