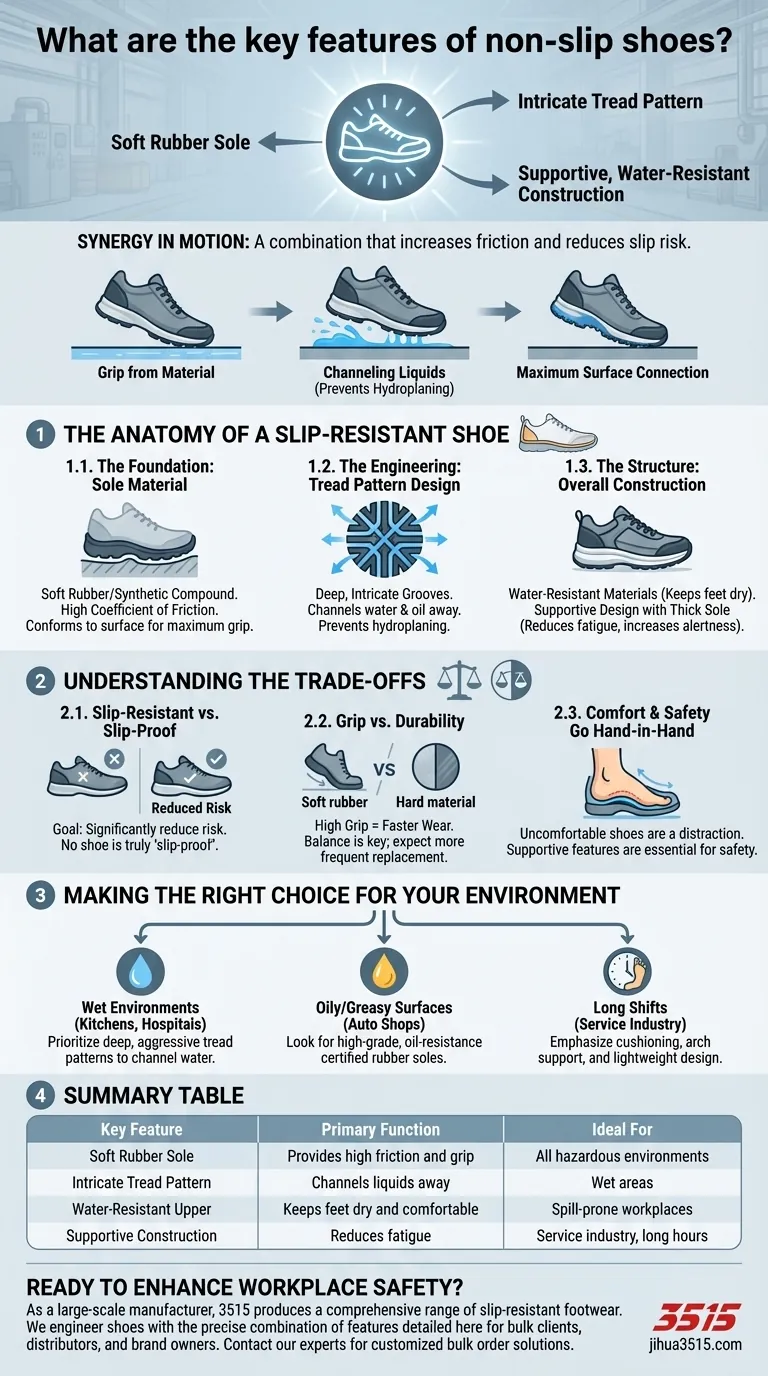

The defining features of a non-slip shoe are a synergistic combination of a soft rubber sole, an intricate tread pattern, and a supportive, water-resistant construction. The sole material provides the essential grip, while the tread is engineered to channel liquids like water and oil away from the point of contact, ensuring the sole maintains maximum surface connection.

The effectiveness of a non-slip shoe is not determined by a single feature, but by how the sole material, tread pattern, and overall shoe design work together to increase friction and reduce the risk of slips on hazardous surfaces.

The Anatomy of a Slip-Resistant Shoe

To truly understand what makes a shoe safe, we must look at its core components. Each element plays a distinct and critical role in providing stability.

The Foundation: Sole Material

The sole is the shoe's first line of defense against a slippery floor. The material used is the single most important factor for grip.

Most high-performance non-slip shoes use soft rubber or a synthetic rubber compound. These materials have a high coefficient of friction, meaning they are naturally "grippy" and resist sliding motions.

Unlike the harder, more durable plastics found on standard footwear, this softer material can better conform to microscopic imperfections in a floor surface, maximizing contact and traction.

The Engineering: Tread Pattern Design

If the sole material provides the grip, the tread pattern ensures that grip can be maintained in the presence of liquids.

Effective non-slip shoes feature deep, intricate, and often multi-directional grooves. This design is not for aesthetics; it serves as a channeling system.

When you step on a wet or oily spot, the liquid is quickly displaced into these grooves and pushed away from the sole's surface. This prevents a layer of liquid from getting trapped under the shoe—a phenomenon known as hydroplaning—which is a primary cause of slips.

The Structure: Overall Construction

Beyond the sole, the shoe's upper construction contributes to both safety and usability, especially for professionals who wear them for long shifts.

Features like water-resistant materials are crucial for keeping feet dry, preventing discomfort and potential health issues.

Furthermore, a supportive design with a thick sole provides essential cushioning. This not only improves comfort but also reduces foot, leg, and back fatigue, helping the wearer stay more alert and stable throughout the day.

Understanding the Trade-offs

No shoe is a perfect solution for every scenario. Acknowledging the inherent compromises is key to making an informed decision.

Slip-Resistant vs. Slip-Proof

It is critical to understand that no shoe is truly "slip-proof." The correct term is slip-resistant, as these shoes are designed to significantly reduce the risk of slipping, not eliminate it entirely.

The Balance Between Grip and Durability

Often, the softest rubber compounds that offer the most aggressive grip may also wear down more quickly than harder materials. Manufacturers constantly work to find a balance, but you should expect that a dedicated work shoe may need to be replaced more frequently than casual footwear to maintain its safety rating.

Comfort and Safety Go Hand-in-Hand

An uncomfortable shoe will not be worn correctly or consistently. Features like a roomy toe box to accommodate natural foot swelling and supportive insoles are not luxuries; they are essential safety components. A shoe that causes pain is a distraction that can lead to an accident.

Making the Right Choice for Your Environment

Your specific workplace environment dictates which features you should prioritize.

- If your primary focus is working in wet environments (e.g., kitchens, hospitals): Prioritize shoes with deep, aggressive tread patterns designed to channel water away quickly.

- If your primary focus is walking on oily or greasy surfaces (e.g., auto shops): Look for a high-grade rubber sole specifically tested and certified for oil resistance.

- If your primary focus is all-day comfort during long shifts (e.g., service industry): Emphasize excellent cushioning, arch support, and a lightweight design in addition to core slip-resistant features.

Ultimately, choosing the right non-slip shoe is an investment in your personal safety and well-being.

Summary Table:

| Key Feature | Primary Function | Ideal For |

|---|---|---|

| Soft Rubber Sole | Provides high friction and grip | All hazardous environments |

| Intricate Tread Pattern | Channels liquids away to prevent hydroplaning | Wet areas (kitchens, hospitals) |

| Water-Resistant Upper | Keeps feet dry and comfortable | Spill-prone workplaces |

| Supportive Construction | Reduces fatigue for long shifts | Service industry, long hours |

Ready to enhance workplace safety with reliable footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of non-slip footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, engineered with the precise combination of soft rubber soles, advanced tread patterns, and ergonomic support detailed in this article.

We help you provide durable, comfortable, and certified slip-resistant footwear that protects your workforce and meets industry standards. Contact our experts today to discuss your bulk order needs and receive a customized solution.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

People Also Ask

- What is the purpose of requiring subjects to wear anti-slip socks and tight-fitting sportswear? Optimize Sensor Data

- Why are metal surfaces often selected as the walking medium in studies concerning ramp safety? Achieve Lab-Grade Precision

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today

- Why is compliance with safety standards such as PN EN ISO 20347:2012 critical? Ensure Certified Workplace Protection