Okay, so I've got this. The user needs clear guidance on how to choose safety shoe materials, not just a list of options. They need to make an informed decision for their specific workplace. That's the core of it. I'm taking on the role of a senior technical advisor, someone trustworthy, objective, and laser-focused on solving the user's actual problem, not just answering a surface-level question. My role here is to guide a fellow expert through a decision making process.

I need to focus on the following:

- Understand Their Deep Need: What's the context? What are the hazards they face? It's not just about the materials; it's about the right shoe for their job to ensure safety, compliance and comfort. This is the WHY behind their request.

- Trustworthy & Expert Voice: I can use the references as starting points but I have to apply my own expertise and synthesize them critically. Absolutely no hallucinating or repeating facts!

My goal here is to give them a clear, scannable guide. I'll use headings, short paragraphs, bolding, and a logical structure to achieve radical clarity. That's how I will be able to help the user.

2. Analyzing the References:

Now, I'll go through the provided references and see what I can get.

- Ref 1: Offers a good starting point (durability, comfort, environmental resistance, breathability, slip resistance), which is useful for the surface need.

- Ref 2: This is the material list (leathers, synthetics, reinforcements) that gives the options. I will have to organize this.

- Ref 3: The shoe breakdown (toe, upper, lining, outsole, midsole, insole) will be perfect for structuring the response.

- Ref 4 & 5: Great for matching materials to specific safety functions (slip-resistant soles, electrical hazard protection, toe caps, etc.).

- Ref 6: This is gold! It's all about environmental assessment: conditions, industry, climate, job role, and frequency of use. This is for the deep need.

- Ref 7 & 8: These are helpful for setting the stage and explaining why the choice matters. They just reiterate common safety standards.

3. Synthesizing & Structuring the Article:

Now, I'll put it all together.

- Opening Hook: The hook will be a bold statement of the core message and a direct list of the key factors from Ref 1. I have to catch the user’s attention and show I understand their needs.

- Core Takeaway Box: Summarize the core message in a way the user can easily refer to. Here, I'll frame the problem and introduce the solution: Analyzing workplace hazards, then matching them to the right shoe materials, and how the shoe is made.

- Main Body: I will use the six-part structure from Ref 3.

- H2: Deconstructing the Safety Shoe: A Material-First Approach: Introduce the structure.

- H3: The Upper: Your First Line of Defense: Discuss Leather vs. Synthetics.

- H3: The Outsole: Your Connection to the Ground: Discuss Rubber, PU, and PVC.

- H3: The Safety Toe: The Core of Impact Protection: Talk Steel vs. Composite vs. Aluminum.

- H3: The Midsole: Puncture and Shock Protection: Mention EVA and Kevlar plates.

- H2: Aligning Materials with Workplace Hazards: This directly addresses the deep need (Ref 6).

- H3: For wet/oily, chemicals, electrical hazards, and falling objects: Recommendations based on the materials from the references.

- H2: Understanding the Trade-offs: This is where I build trust.

- H3: Durability vs. Comfort, Breathability vs. Water Resistance, and Cost vs. Performance.

- Concluding Section:

- H2: Making the Right Choice for Your Role: I'll use a bulleted list to offer actionable recommendations based on their different jobs. This is how I ensure the user gets something concrete out of this whole thing.

- Final Empowering Sentence: A concise summary.

This approach will provide a comprehensive, actionable guide to help the user make the right choice. Choosing the right safety shoe material is about matching its properties to your specific work environment. The key factors to consider are durability, comfort, and targeted resistance. This means evaluating a material's ability to withstand abrasion, water, and chemicals while also providing critical features like slip resistance, breathability, and impact protection for the toe.

The most effective way to select safety footwear is to stop thinking about the shoe as a single item. Instead, analyze your workplace hazards first, then map those needs to the specific materials used in each critical part of the shoe—the upper, the outsole, and the safety toe.

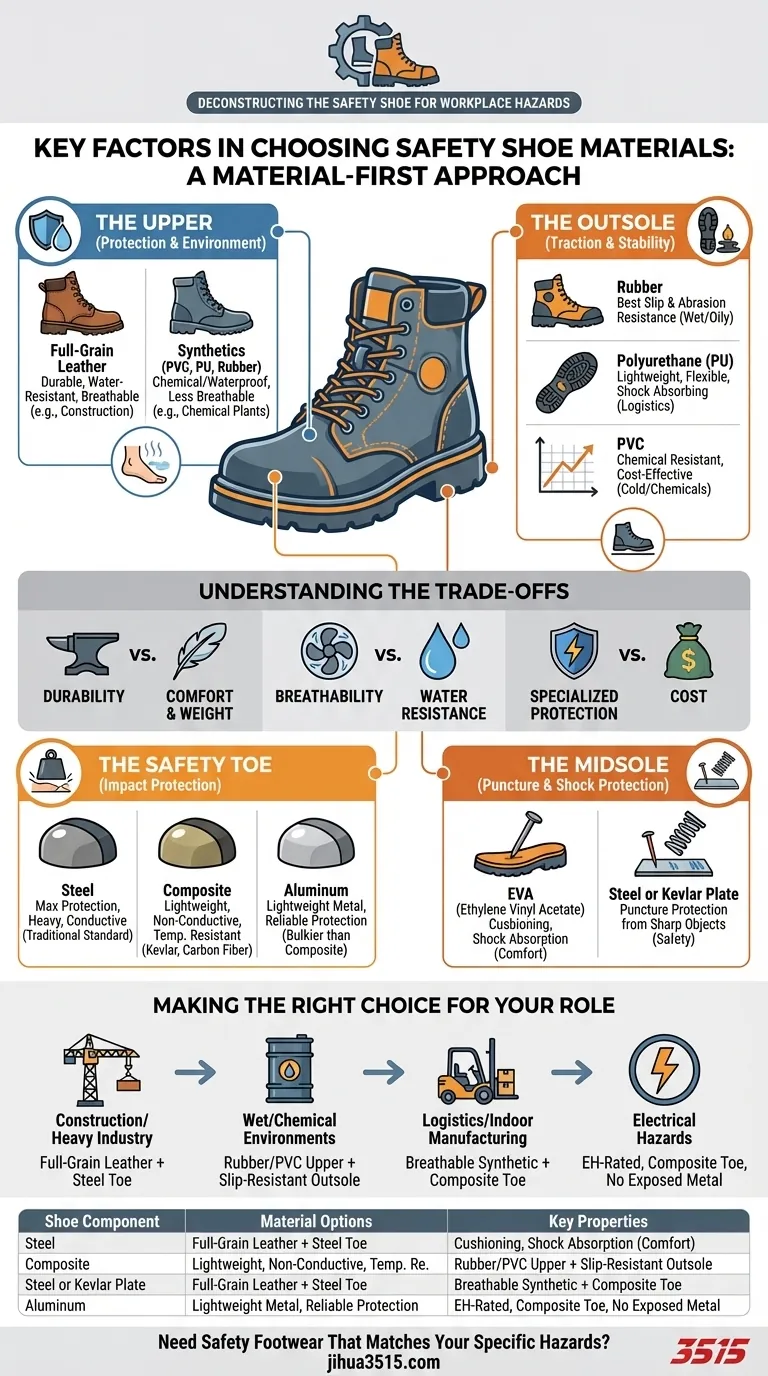

Deconstructing the Safety Shoe: A Material-First Approach

A safety shoe is a system of components, each requiring a specific material to perform its function. Understanding these parts is the first step toward making an informed choice.

The Upper: Your First Line of Defense

The upper is the largest part of the shoe and protects your foot from splashes, sparks, and abrasions.

- Full-Grain Leather: Offers excellent durability, water resistance, and breathability. It's the premium choice for rugged environments like construction.

- Nubuck or Suede Leather: Softer and more flexible than full-grain leather, providing more comfort but slightly less durability and water resistance.

- Synthetics (PVC, PU, Rubber): These materials provide superior resistance to chemicals and are fully waterproof. They are ideal for food processing or chemical plants but offer limited breathability.

The Outsole: Your Connection to the Ground

The outsole dictates traction and stability. Its material composition is critical for preventing slips, trips, and falls.

- Rubber: Provides the best slip resistance on wet and oily surfaces. It is also highly resistant to abrasion and heat.

- Polyurethane (PU): A lightweight and flexible material that offers excellent shock absorption and comfort for long periods of standing, common in logistics or light manufacturing.

- PVC: A cost-effective option that holds up well against chemicals and abrasion but can be less flexible and slip-resistant, especially in cold temperatures.

The Safety Toe: The Core of Impact Protection

This is the most well-known safety feature, designed to protect your toes from compression and falling objects.

- Steel: The traditional standard, offering maximum protection. However, it is the heaviest option and conducts temperature.

- Composite: Made from non-metal materials like carbon fiber or Kevlar. It is much lighter than steel, does not conduct electricity, and is better in extreme temperatures.

- Aluminum: A lightweight metal alternative that provides reliable protection but can be bulkier than a composite toe.

The Midsole: Puncture and Shock Protection

The midsole provides cushioning and can also house a protective plate to prevent punctures from below.

- EVA (Ethylene Vinyl Acetate): A foam-like material that provides excellent cushioning and shock absorption, enhancing comfort.

- Steel or Kevlar Plate: A thin plate embedded in the midsole to protect against punctures from nails, glass, or other sharp objects on the ground.

Understanding the Trade-offs

No single material is perfect for every situation. Being aware of the inherent compromises is key to selecting the right shoe.

Durability vs. Comfort & Weight

Heavy-duty materials like full-grain leather and steel toes offer maximum protection and longevity. The trade-off is often increased weight and rigidity, which can lead to fatigue over a long shift. Lighter composite materials and flexible uppers improve comfort but may not withstand the most abrasive environments.

Breathability vs. Water Resistance

A fully waterproof material like rubber or PVC will keep your feet dry from external moisture but will also trap sweat, leading to discomfort. Materials like treated leather or specialized synthetic fabrics offer a balance, providing good water resistance while still allowing some moisture vapor to escape.

Specialized Protection vs. Cost

Advanced materials that offer specific benefits—such as electrical hazard (EH) resistance, extreme temperature insulation, or puncture-proof Kevlar plates—come at a higher cost. It is essential to invest in the features your specific job requires and avoid paying for protections you do not need.

Making the Right Choice for Your Role

Begin with a simple assessment of your daily tasks and environment. This will immediately clarify which materials offer you the most effective protection.

- If your primary focus is construction or heavy industry: Prioritize durability with a full-grain leather upper and a steel toe for maximum impact resistance.

- If your primary focus is working in wet or chemical environments: Select footwear with a waterproof rubber or PVC upper and a slip-resistant rubber outsole.

- If your primary focus is logistics or indoor manufacturing: Consider a lighter option with a breathable synthetic upper and a composite toe for all-day comfort and protection.

- If your primary focus is avoiding electrical hazards: Insist on EH-rated shoes with a non-conductive composite toe and ensure no metal parts are exposed.

By systematically matching the material of each shoe component to your specific hazards, you can select footwear that offers uncompromising safety and performance.

Summary Table:

| Shoe Component | Material Options | Key Properties |

|---|---|---|

| Upper | Full-Grain Leather, Synthetics (PVC, Rubber) | Durability, Water/Chemical Resistance, Breathability |

| Outsole | Rubber, Polyurethane (PU), PVC | Slip Resistance, Abrasion Resistance, Flexibility |

| Safety Toe | Steel, Composite, Aluminum | Impact Protection, Weight, Electrical Hazard Rating |

| Midsole | EVA, Steel/Kevlar Plate | Cushioning, Puncture Protection |

Need Safety Footwear That Matches Your Specific Hazards?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, from chemical-resistant rubber boots to lightweight composite-toe shoes for logistics. We can help you select or customize the perfect footwear solution based on your unique workplace demands.

Contact our experts today for a consultation on durable, comfortable, and compliant safety footwear.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Wholesale Leather Safety Boots with Customizable Protective Toe

People Also Ask

- What is the purpose of requiring subjects to wear anti-slip socks and tight-fitting sportswear? Optimize Sensor Data

- How do athletic-style safety shoes balance flexibility and safety? Perfect Agility for Active Professionals

- How do industrial safety shoes contribute to safety in sugar production? Ensure High-Altitude Inspection Security

- Why is compliance with safety standards such as PN EN ISO 20347:2012 critical? Ensure Certified Workplace Protection

- Why are industrial-grade safety shoes mandatory in metallurgical workshops? Essential Protection for Extreme Environments