To choose the right insulated work boots, you must balance three core factors: the level of insulation required for your climate and activity level, the non-negotiable safety features mandated by your job, and the essential comfort and fit needed for long-term wear. The ideal boot is not simply the warmest or the toughest, but the one that correctly synthesizes these elements for your specific environment.

The most common mistake is over-insulating. The right boot isn't the one with the most insulation; it's the one with the right amount of insulation for how much you move. Your activity level is just as important as the thermometer.

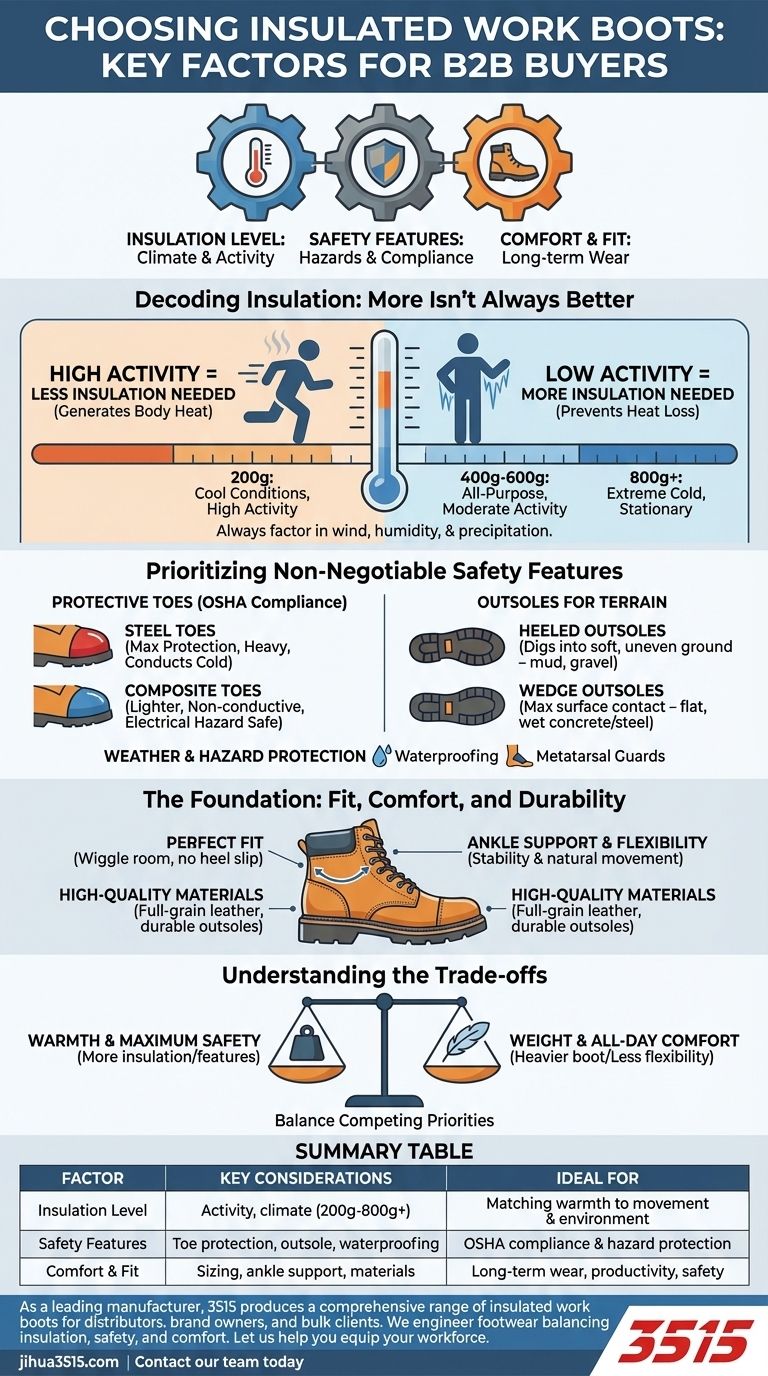

Decoding Insulation: More Isn't Always Better

The primary function of an insulated boot is to trap your body's natural heat. Understanding how this works is the first step in making an intelligent choice.

The Role of Your Activity Level

Your level of physical exertion is the most critical factor. An active worker generates significant body heat, requiring less insulation to stay warm.

A stationary worker, however, generates very little heat and needs much heavier insulation to compensate and prevent heat loss.

Understanding Insulation Grams

Insulation is measured in grams. While not a perfect system, it provides a reliable baseline for comparing warmth.

- 200g: Best for cool conditions or high activity levels where you're constantly moving.

- 400g-600g: An excellent all-purpose choice for cold weather and moderate activity. This is a common sweet spot for many outdoor trades.

- 800g+: Designed for extremely cold, frigid conditions, especially when you will be stationary for long periods.

Matching Insulation to Your Environment

Consider your typical weather conditions. A boot for a cold, wet construction site in the Pacific Northwest has different needs than one for a frozen oil field in North Dakota. Always factor in wind, humidity, and precipitation.

Prioritizing Non-Negotiable Safety Features

Beyond warmth, a work boot is a critical piece of personal protective equipment. The safety features you need are dictated entirely by the hazards of your workplace.

Protective Toes: Steel vs. Composite

Your job may have OSHA requirements for toe protection against compression or falling objects.

Steel toes offer maximum protection but are heavier and conduct cold. Composite toes are lighter, don't conduct cold, and are ideal for environments with electrical hazards, while still meeting safety standards.

The Right Outsole for Your Terrain

Traction is paramount for preventing slips and falls. The sole of your boot should match the surfaces you walk on most.

Heeled outsoles are excellent for digging into soft, uneven ground like mud or gravel. Wedge outsoles provide maximum surface contact, making them superior for flat, often wet surfaces like concrete or steel platforms.

Essential Weather and Hazard Protection

Waterproofing is a must for almost any outdoor work to keep feet dry and prevent heat loss.

For environments with risks from above, metatarsal guards offer crucial protection for the delicate bones on the top of your foot.

The Foundation: Fit, Comfort, and Durability

Even the warmest, safest boot is useless if it's too painful to wear. Comfort is not a luxury; it's a prerequisite for productivity and safety.

Why a Perfect Fit Is a Safety Feature

A poorly fitting boot can cause blisters, hot spots, and fatigue, distracting you from your work and increasing the risk of accidents. There should be enough room to wiggle your toes, but your heel should not slip when you walk.

Ankle Support and Flexibility

Proper ankle support helps prevent sprains and provides stability on uneven ground. However, this must be balanced with enough flexibility to allow for natural movement without restricting you.

High-Quality Materials

Look for durable materials like full-grain leather for the upper and robust polyurethane or rubber for the outsole. High-quality construction and materials ensure the boot will last and protect you for its entire lifespan.

Understanding the Trade-offs

Choosing the perfect boot always involves balancing competing priorities. Being aware of these compromises is the mark of an informed buyer.

Warmth vs. Weight

Heavier insulation (more grams) adds weight and bulk. This can lead to fatigue over a long workday, especially if your job requires a lot of walking. Sometimes, a slightly less insulated but lighter boot is the better choice for active workers.

Maximum Safety vs. All-Day Comfort

Features like steel toes and heavy-duty metatarsal guards add significant weight and can reduce flexibility. You must select the features your job requires without adding unnecessary elements that will detract from comfort.

Price vs. Longevity

While budget is always a factor, the highest-quality materials and construction methods cost more upfront. Investing in a durable, well-made boot from a reputable brand often saves money by lasting significantly longer than cheaper alternatives.

Making the Right Choice for Your Job

Filter your options through the lens of your daily work environment to find the perfect boot.

- If your primary focus is working in extreme cold with low activity (e.g., a security guard, ice fisher): Prioritize the highest insulation gram count (800g+) and ensure a comfortable fit with room for thick socks.

- If your primary focus is active work in cold, wet conditions (e.g., a construction worker, utility lineman): Choose moderate insulation (400g-600g) with excellent waterproofing and a flexible, slip-resistant outsole suited to your terrain.

- If your primary focus is safety compliance in a moderately cool environment (e.g., a warehouse worker, mechanic): Select the lightest effective insulation (200g-400g) and focus on getting the specific safety toe (composite/steel) and slip-resistance required by your job.

Ultimately, your insulated work boot is a critical tool engineered for a specific task—choose it with the same care you would any other piece of essential equipment.

Summary Table:

| Factor | Key Considerations | Ideal For |

|---|---|---|

| Insulation Level | Activity level, climate (200g-800g+) | Matching warmth to movement & environment |

| Safety Features | Toe protection (steel/composite), outsole type, waterproofing | OSHA compliance & hazard protection |

| Comfort & Fit | Proper sizing, ankle support, material quality | Long-term wear, productivity, and safety |

As a leading manufacturer, 3515 produces a comprehensive range of insulated work boots for distributors, brand owners, and bulk clients.

We engineer footwear that perfectly balances insulation, critical safety features, and all-day comfort to meet the specific demands of your target market. Our production capabilities encompass all types of safety boots and boots, ensuring durability and compliance.

Let us help you equip your workforce with the right tools for the job. Contact our team today to discuss your specific requirements and explore our catalog.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- What is TPU and why is it used in work boots? | Lightweight Armor for Durability

- How do lace-to-toe boots differ from traditional lacing designs? Unlock a Custom Fit & Superior Support

- What makes Goodyear Welt boots suitable for harsh environments? Unmatched Durability & Repairability

- What are the best storage practices for fire boots? Keep Your Gear Ready & Extend Its Lifespan

- How have engineer boots influenced women's fashion? A Symbol of Rugged, Androgynous Style

- What additional safety features might work boots have? Essential Protection for Your Job Site

- How should new leather work boots be broken in? A Guide to Comfort and Durability

- What is the difference between waterproof, water-resistant, and water-repellent boots? Choose the Right Protection for Your Feet