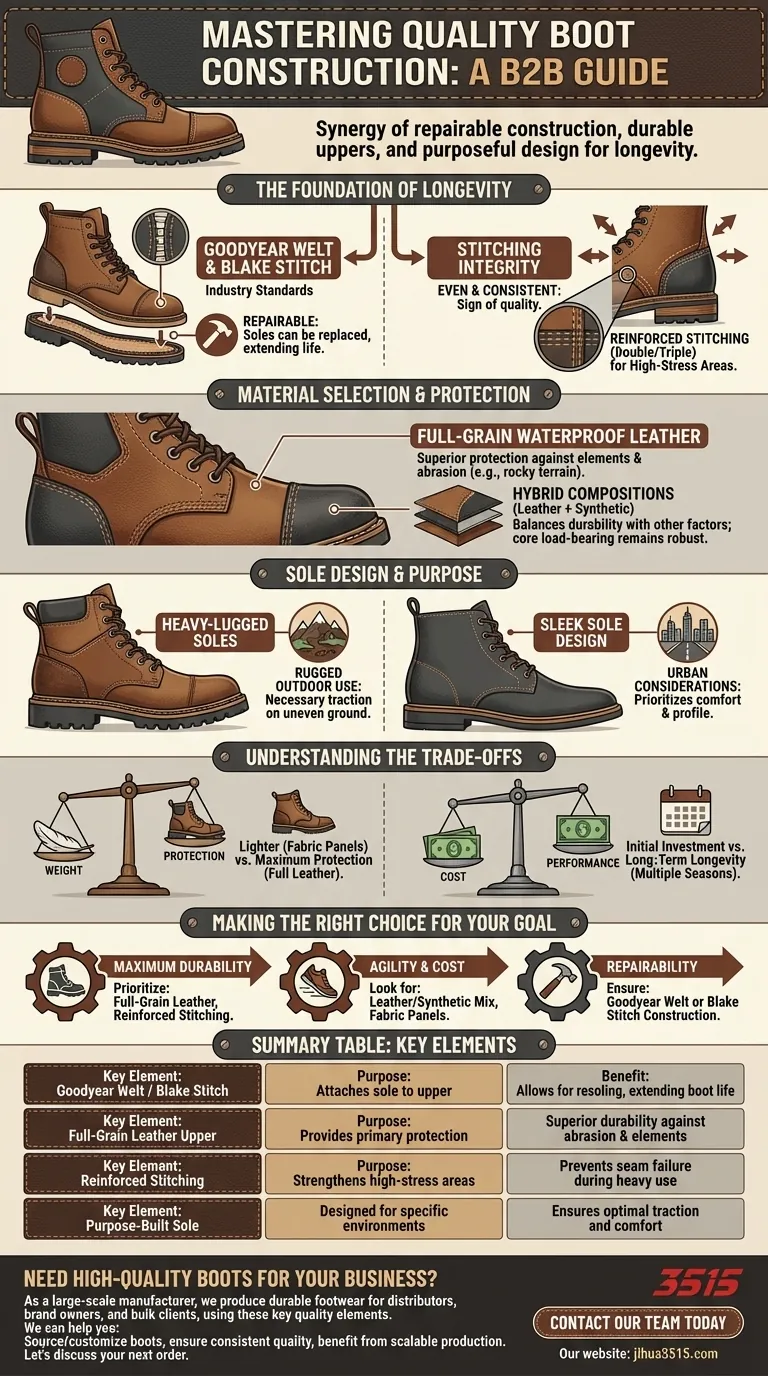

The hallmarks of quality boot construction are durable assembly techniques like Goodyear welting or Blake stitching, combined with premium materials such as full-grain leather. A well-constructed boot features reinforced stitching and a sole design specifically engineered for its intended environment, ensuring longevity and performance.

True quality is defined by the synergy of repairable construction methods, durable uppers, and purposeful design. These elements ensure the boot provides flexibility and lasts through multiple seasons of use.

The Foundation of Longevity

Primary Construction Methods

The method used to attach the sole to the upper is the primary indicator of a boot's lifespan. Goodyear welt and Blake stitch constructions are the industry standards for quality.

These methods are superior because they allow for repairability. Unlike glued footwear, boots built this way can often be resoled, extending their life significantly.

Stitching Integrity

You can identify quality by examining the stitching details. Look for stitching that is even and consistent throughout the boot.

High-end construction utilizes reinforced stitching. This often appears as double or triple-stitching in high-stress areas to prevent failure during heavy use.

Material Selection and Protection

The Upper Standards

The durability of the upper—the part of the boot covering your foot—is critical. The top-tier material for this component is full grain waterproof leather.

Leather provides superior protection against elements and abrasion. This is particularly vital in environments like rocky terrain, where thinner materials might fail.

Hybrid Compositions

Many modern boots utilize a combination of materials. It is common to see designs that blend leather with synthetic materials.

This approach allows manufacturers to balance durability with other factors. However, the core load-bearing and protective elements should remain robust.

Sole Design and Purpose

Traction and Tread

The design of the sole must match the boot's intended function. A "one-size-fits-all" approach is rarely a sign of quality.

For rugged outdoor use, look for heavy-lugged soles. These provide necessary traction on uneven or slippery ground.

Urban Considerations

Conversely, boots designed for city environments require a different approach. A sleek sole design is more appropriate here, prioritizing comfort and profile over aggressive grip.

Understanding the Trade-offs

Weight vs. Protection

While full leather offers the best protection, it comes with a weight penalty. Fabric panels are often introduced to reduce the overall weight of the boot.

If you choose a lighter boot with more fabric, you are trading maximum physical protection for reduced fatigue.

Cost vs. Performance

Incorporating fabric panels can also reduce the manufacturing cost compared to full leather builds.

However, for long-term use across multiple hunting seasons or work environments, the initial investment in higher-grade materials often pays off through increased longevity.

Making the Right Choice for Your Goal

To select the right boot, you must align the construction elements with your specific needs.

- If your primary focus is Maximum Durability: Prioritize full grain waterproof leather and reinforced stitching to withstand rocky terrain and multiple seasons of wear.

- If your primary focus is Agility and Cost: Look for leather/synthetic combinations or fabric panels that reduce weight while maintaining acceptable durability.

- If your primary focus is Repairability: Ensure the boot uses Goodyear welt or Blake stitch construction so the soles can be replaced when worn down.

Quality is not just about the price tag, but about selecting the right materials and construction for your specific environment.

Summary Table:

| Key Element | Purpose | Benefit |

|---|---|---|

| Goodyear Welt / Blake Stitch | Attaches sole to upper | Allows for resoling, extending boot life |

| Full-Grain Leather Upper | Provides primary protection | Superior durability against abrasion & elements |

| Reinforced Stitching | Strengthens high-stress areas | Prevents seam failure during heavy use |

| Purpose-Built Sole | Designed for specific environments | Ensures optimal traction and comfort |

Need High-Quality Boots for Your Business?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of boots, built with the key quality elements discussed—from repairable Goodyear welting to premium full-grain leather uppers.

We can help you:

- Source or customize boots tailored to your specific market needs and environments.

- Ensure consistent quality and durability for your customers.

- Benefit from scalable production and competitive pricing.

Let's discuss your next order. Contact our team today to explore how we can build long-lasting value for your business.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?