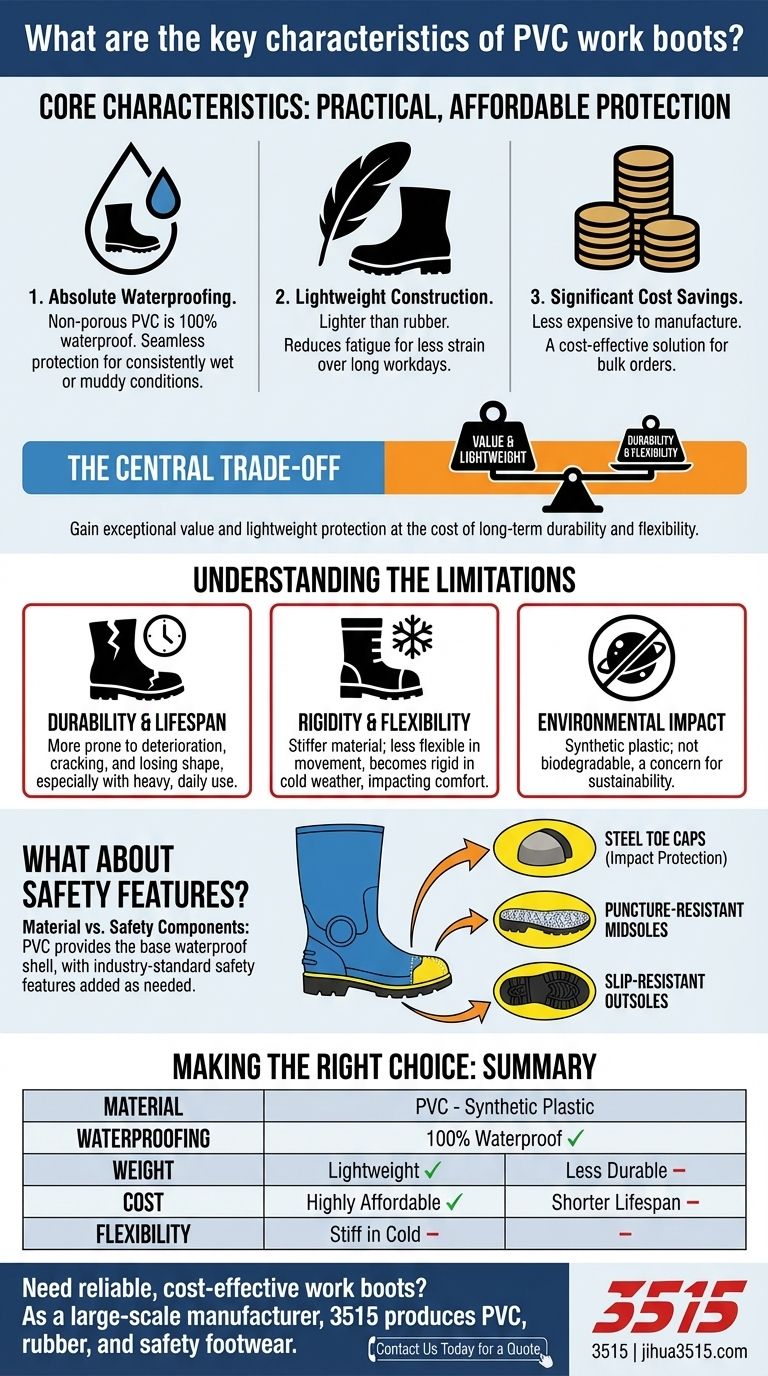

At their core, PVC work boots are defined by three main characteristics: they are completely waterproof, exceptionally lightweight, and significantly more affordable than their rubber or neoprene counterparts. These qualities make them a practical choice for a wide range of applications where keeping feet dry from water and some chemicals is the primary concern.

The central trade-off with PVC work boots is clear: you gain exceptional value and lightweight water protection at the cost of long-term durability and flexibility, especially when compared to more premium materials like rubber.

The Core Advantages of PVC Boots

The popularity of PVC (Polyvinyl Chloride) as a boot material stems from a few powerful, practical benefits that align with the needs of many work environments.

Absolute Waterproofing

Because PVC is a non-porous plastic, boots made from it are 100% waterproof. This seamless protection is their most fundamental and reliable feature, making them ideal for work in consistently wet or muddy conditions.

Lightweight Construction

PVC is inherently lighter than traditional rubber. This reduction in weight translates directly to less fatigue for the wearer over a long workday, a critical factor in jobs that require constant standing or walking.

Significant Cost Savings

One of the most compelling reasons to choose PVC is its affordability. These boots are generally less expensive to manufacture than those made from rubber or neoprene, making them a highly cost-effective solution for individuals and companies.

Reliable Chemical Resistance

PVC offers strong protection against a variety of acids, fats, oils, and other common industrial chemicals. While the specific level of resistance can vary by model, it provides a dependable barrier in many agricultural and processing environments.

Understanding the Trade-offs

While PVC offers clear advantages, it's crucial to understand its limitations. These trade-offs are what separate it from more expensive alternatives and define where it may not be the best fit.

Durability and Lifespan

The primary drawback of PVC is its durability. Compared to rubber, it is more prone to deteriorating, cracking, or losing its original shape over time, especially with heavy, daily use.

Rigidity and Flexibility

PVC is a stiffer material than rubber. This can make the boots feel less flexible during movement and become particularly rigid in cold weather, which can impact comfort and mobility.

Environmental Impact

As a synthetic plastic, PVC is not biodegradable. For individuals or organizations focused on environmental sustainability, this is a significant factor to consider.

What About Safety Features?

It's important to distinguish between the boot's material and its integrated safety components. The characteristics of PVC define the boot's base performance, but they are often enhanced with industry-standard protective hardware.

The Material vs. The Boot

While PVC provides the waterproof and chemical-resistant shell, it does not inherently offer impact or puncture protection. These features must be added to the boot's design.

Common Safety Additions

Most heavy-duty PVC work boots incorporate crucial safety elements to meet job-site requirements. These frequently include steel toe caps for impact protection, puncture-resistant midsoles, and slip-resistant outsoles.

Making the Right Choice for Your Goal

Selecting the correct boot depends entirely on balancing your budget, required protection, and work environment.

- If your primary focus is budget and reliable water protection for moderate use: PVC boots offer an unmatched combination of performance and value.

- If your primary focus is long-term durability for daily, rugged work: You should strongly consider investing in a more durable material like rubber.

- If your primary focus is comfort and flexibility, especially in cold climates: The inherent stiffness of PVC may be a significant drawback, making rubber or neoprene a better choice.

Understanding these core characteristics ensures you select a boot that aligns perfectly with your work environment and priorities.

Summary Table:

| Characteristic | Advantage | Trade-off |

|---|---|---|

| Material | PVC (Polyvinyl Chloride) | Synthetic Plastic |

| Waterproofing | 100% Waterproof | - |

| Weight | Lightweight, Reduces Fatigue | Less Durable than Rubber |

| Cost | Highly Affordable | Shorter Lifespan |

| Flexibility | - | Stiff, Especially in Cold |

Need reliable, cost-effective work boots for your team? As a large-scale manufacturer, 3515 produces a comprehensive range of PVC, rubber, and safety footwear for distributors, brand owners, and bulk clients. We can provide the perfect balance of waterproof protection, lightweight comfort, and critical safety features your business requires. Contact us today for a quote and discover how we can support your supply chain with high-quality, affordable footwear solutions!

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- How does a reinforced heel counter benefit firefighter boots? Lock in Stability for Safer, More Effective Response

- How does the outsole of Mortar boots perform in cold and wet conditions? Engineered for Superior Traction & Safety

- How are insulated boots rated for different temperature conditions? Match Your Activity Level for Optimal Warmth

- What activities are packer boots suitable for? The Ultimate Hybrid Boot for Riding and Work

- What are Yard boots designed for? Specialized Footwear for Stable & Farm Work

- What are the concerns about purchasing biking-specific boots? Balancing Cost, Safety & Versatility

- What are the key benefits of Western work boots? Superior Protection, Comfort & Style

- What is the difference between a packer boot and a logger boot? Choose the Right Work & Western Footwear