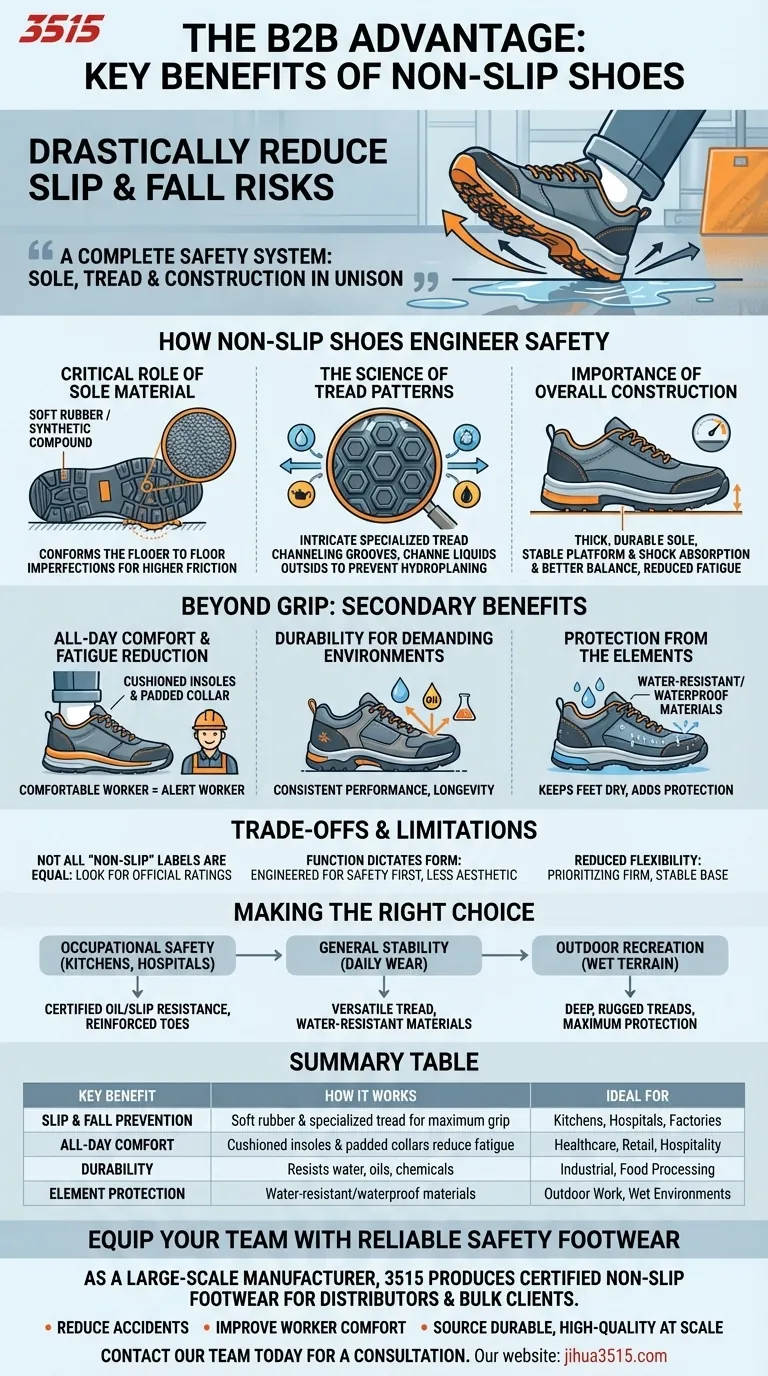

The primary benefit of non-slip shoes is their ability to drastically reduce the risk of slips and falls in hazardous environments. They achieve this by engineering a superior connection between the shoe and the ground, providing exceptional traction, stability, and all-day support where it is needed most.

The true value of a non-slip shoe isn't just its grip; it's a complete safety system. The sole material, tread design, and overall construction work in unison to provide stability and reduce fatigue, directly preventing accidents in slippery conditions.

How Non-Slip Shoes Engineer Safety

The effectiveness of a non-slip shoe is not accidental. It is the result of specific design choices that address the physics of a slip.

The Critical Role of Sole Material

The foundation of a non-slip shoe is its outsole, which is typically made from soft rubber or a synthetic rubber compound.

Unlike harder materials, this softer rubber has a higher coefficient of friction, allowing it to better conform to microscopic imperfections in a floor's surface and create a stronger grip.

The Science of Tread Patterns

A flat sole on a wet surface can lead to hydroplaning, where a layer of liquid prevents the shoe from making contact with the ground.

Non-slip shoes feature intricate and specialized tread patterns. These small, often circular or hexagonal grooves are designed to channel liquids like water and oil out from under the sole, ensuring the rubber maintains direct contact with the floor.

The Importance of Overall Construction

Effective non-slip shoes are built for stability. They often feature thicker, more durable soles than standard footwear.

This robust construction not only provides a stable platform for the foot but also absorbs shock, which contributes to better balance and reduces foot and back fatigue during long periods of standing or walking.

Beyond Grip: The Secondary Benefits

While preventing falls is the main objective, high-quality non-slip shoes offer several other crucial advantages, particularly in professional settings.

All-Day Comfort and Fatigue Reduction

Many non-slip models are designed for long shifts and include features like cushioned insoles and padded collars.

By reducing physical fatigue, these comfort features also enhance safety. A comfortable worker is a more alert worker, less prone to making errors or losing balance at the end of a long day.

Durability for Demanding Environments

Occupational footwear is an investment in safety, and it must withstand harsh conditions.

The materials used in non-slip shoes are chosen for durability and longevity, ensuring they perform consistently over time without degrading from exposure to water, oils, or cleaning chemicals.

Protection from the Elements

Many non-slip shoes are built with water-resistant or waterproof materials. This feature keeps the wearer's feet dry, preventing discomfort and potential health issues while adding another layer of protection in wet environments.

Understanding the Trade-offs and Limitations

To make an informed decision, it's important to recognize the potential compromises and what to look for.

Not All "Non-Slip" Labels Are Equal

The term "non-slip" is not always standardized. Always look for official slip-resistant labeling or ratings that indicate the shoe has been tested for performance on various surfaces.

Function Often Dictates Form

The most effective non-slip shoes are engineered for safety first. While styles have become much more versatile, the primary focus on thick soles and specific materials may limit their aesthetic appeal compared to high-fashion footwear.

Potential for Reduced Flexibility

The same thick, supportive sole that provides stability can sometimes be less flexible than a casual sneaker. This is a deliberate trade-off, prioritizing a firm, stable base over the pliability needed for certain athletic activities.

Making the Right Choice for Your Goal

Select your footwear based on the specific demands of your environment.

- If your primary focus is occupational safety (kitchens, hospitals): Prioritize shoes with certified oil and slip resistance and features like reinforced toes if required by your workplace.

- If your primary focus is general stability for daily wear: Look for a versatile tread pattern and water-resistant materials that balance comfort with reliable traction.

- If your primary focus is outdoor recreation on wet terrain: Choose footwear with deep, rugged treads designed to grip uneven surfaces and provide maximum water protection.

Ultimately, choosing the right non-slip shoe is a proactive investment in your personal safety and stability.

Summary Table:

| Key Benefit | How It Works | Ideal For |

|---|---|---|

| Slip & Fall Prevention | Soft rubber soles & specialized tread patterns channel liquids for maximum grip. | Kitchens, Hospitals, Factories |

| All-Day Comfort & Support | Cushioned insoles and padded collars reduce fatigue during long shifts. | Healthcare, Retail, Hospitality |

| Durability in Harsh Conditions | Materials resist degradation from water, oils, and chemicals. | Industrial, Food Processing, Cleaning |

| Water & Element Protection | Water-resistant or waterproof materials keep feet dry and safe. | Outdoor Work, Wet Environments |

Ready to Equip Your Team with Reliable Safety Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified non-slip footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, engineered with the precise sole materials and tread patterns detailed above to ensure maximum protection and comfort.

We help you:

- Reduce workplace accidents with tested, reliable traction.

- Improve worker comfort and productivity with ergonomic designs.

- Source durable, high-quality footwear at a competitive scale.

Let's discuss your specific needs. Contact our team today for a consultation and see how we can support your safety goals.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

People Also Ask

- Why are industrial-grade safety shoes mandatory in metallurgical workshops? Essential Protection for Extreme Environments

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now

- Why are metal surfaces often selected as the walking medium in studies concerning ramp safety? Achieve Lab-Grade Precision

- Why is compliance with safety standards such as PN EN ISO 20347:2012 critical? Ensure Certified Workplace Protection