While leather remains a benchmark material for safety footwear, its primary disadvantages are rooted in its organic nature. It is highly susceptible to environmental degradation, demands consistent maintenance to preserve its integrity, and can become compromised in persistently wet conditions, making it less suitable for certain work environments compared to modern synthetic alternatives.

The core issue is not that leather is a poor material, but that it represents a trade-off. You gain exceptional durability, comfort, and breathability in exchange for a mandatory commitment to regular care and a vulnerability to specific environmental stresses.

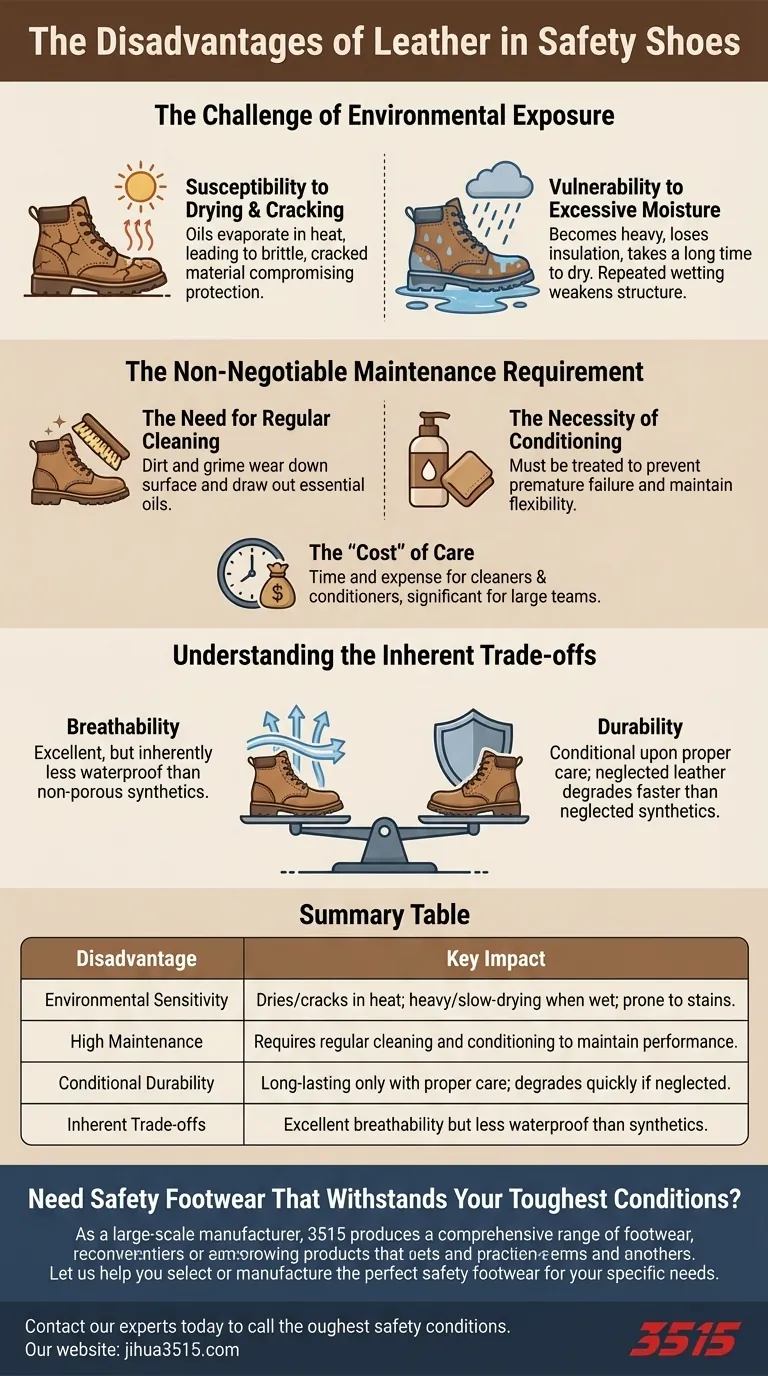

The Challenge of Environmental Exposure

Leather's performance is intrinsically linked to its environment. As a natural material, it reacts to external conditions in ways that synthetics do not, which can present significant drawbacks in demanding workplaces.

Susceptibility to Drying and Cracking

Leather contains natural oils that keep it flexible and strong. In hot, arid conditions or with prolonged exposure to heat sources, these oils can evaporate, causing the material to dry out, become brittle, and eventually crack, compromising its protective qualities.

Vulnerability to Excessive Moisture

While leather has excellent breathability and can absorb perspiration, it is also highly absorbent of external liquids. When saturated, it becomes heavy, loses its insulating properties, and can take a very long time to dry. This repeated cycle of getting wet and drying can strip the leather of its oils and weaken its structure.

Potential for Staining and Damage

As a porous material, leather is prone to staining from oils, chemicals, and other workplace contaminants. It is also more sensitive to physical damage like deep scuffs and cuts compared to some hard-shell synthetic materials.

The Non-Negotiable Maintenance Requirement

Unlike "set-and-forget" synthetic footwear, leather requires an ongoing investment of time and effort to maintain its performance and longevity. This is a critical factor in the total cost of ownership.

The Need for Regular Cleaning

Dirt, dust, and grime are not just cosmetic issues. These particles can be abrasive, slowly wearing down the leather's surface. More importantly, they can draw out the essential oils, accelerating the drying process.

The Necessity of Conditioning

To counteract the loss of natural oils from exposure and cleaning, leather must be regularly treated with a conditioner. Skipping this step is the primary reason leather footwear fails prematurely, losing its flexibility and water resistance.

The "Cost" of Care

This required maintenance translates to a real cost, both in time spent on upkeep and the expense of purchasing quality cleaners and conditioners. For large teams, this can represent a significant operational consideration.

Understanding the Inherent Trade-offs

Choosing leather is about accepting a specific set of compromises. Acknowledging these trade-offs is essential for making an informed decision and avoiding common pitfalls.

Breathability vs. Water Resistance

Leather's natural pores provide excellent breathability, allowing foot vapor to escape and regulating temperature effectively. However, these same pores make it inherently less waterproof than non-porous synthetic materials. While treatments can improve water resistance, they often slightly reduce breathability.

Durability vs. Neglect

Well-maintained leather is exceptionally durable and can outlast many synthetic options. However, its durability is conditional upon proper care. A neglected leather boot will degrade much faster than a neglected synthetic one, making it a poor choice for users unwilling or unable to perform routine maintenance.

Making the Right Choice for Your Goal

Your decision should be dictated by your daily environment and your tolerance for a regular maintenance schedule.

- If your primary focus is maximum durability in dry to moderately damp conditions: Leather is an outstanding choice, provided you commit to a consistent cleaning and conditioning routine.

- If your primary focus is working in consistently wet, muddy, or chemical-heavy environments: You should strongly consider modern synthetic alternatives that offer superior, low-maintenance water and chemical resistance.

- If your primary focus is minimal maintenance and lightweight performance: Synthetic materials will almost always provide a better solution, offering reliable protection without the need for ongoing care.

Ultimately, understanding these limitations empowers you to leverage leather's undeniable strengths where they matter most.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Environmental Sensitivity | Dries/cracks in heat; heavy/slow-drying when wet; prone to stains. |

| High Maintenance | Requires regular cleaning and conditioning to maintain performance. |

| Conditional Durability | Long-lasting only with proper care; degrades quickly if neglected. |

| Inherent Trade-offs | Excellent breathability but less waterproof than synthetics. |

Need Safety Footwear That Withstands Your Toughest Conditions?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including high-performance synthetic alternatives designed for wet, chemical-heavy, or low-maintenance environments.

Let us help you select or manufacture the perfect safety footwear for your specific needs.

Contact our experts today for a consultation to discuss durability, materials, and custom solutions.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

- Wholesale Comfort Leather Business Shoes with Dial Lacing System

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Factory Direct Wholesale Leather Comfort Shoes with Dial Closure

People Also Ask

- Why are metal surfaces often selected as the walking medium in studies concerning ramp safety? Achieve Lab-Grade Precision

- Why are industrial-grade safety shoes mandatory in metallurgical workshops? Essential Protection for Extreme Environments

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now

- How do athletic-style safety shoes balance flexibility and safety? Perfect Agility for Active Professionals

- Why is compliance with safety standards such as PN EN ISO 20347:2012 critical? Ensure Certified Workplace Protection