The primary materials for rain boots are natural rubber, synthetic rubber, Polyvinyl Chloride (PVC), and Ethylene Vinyl Acetate (EVA). While traditional boots rely on the natural waterproofing of rubber, modern manufacturing has introduced a range of synthetic plastics, each offering a unique profile of weight, durability, and cost.

The material of a rain boot is not just about keeping your feet dry; it is the core factor that dictates the boot's durability, comfort, weight, and performance in different weather conditions. Understanding the trade-offs between these materials is key to choosing the right pair.

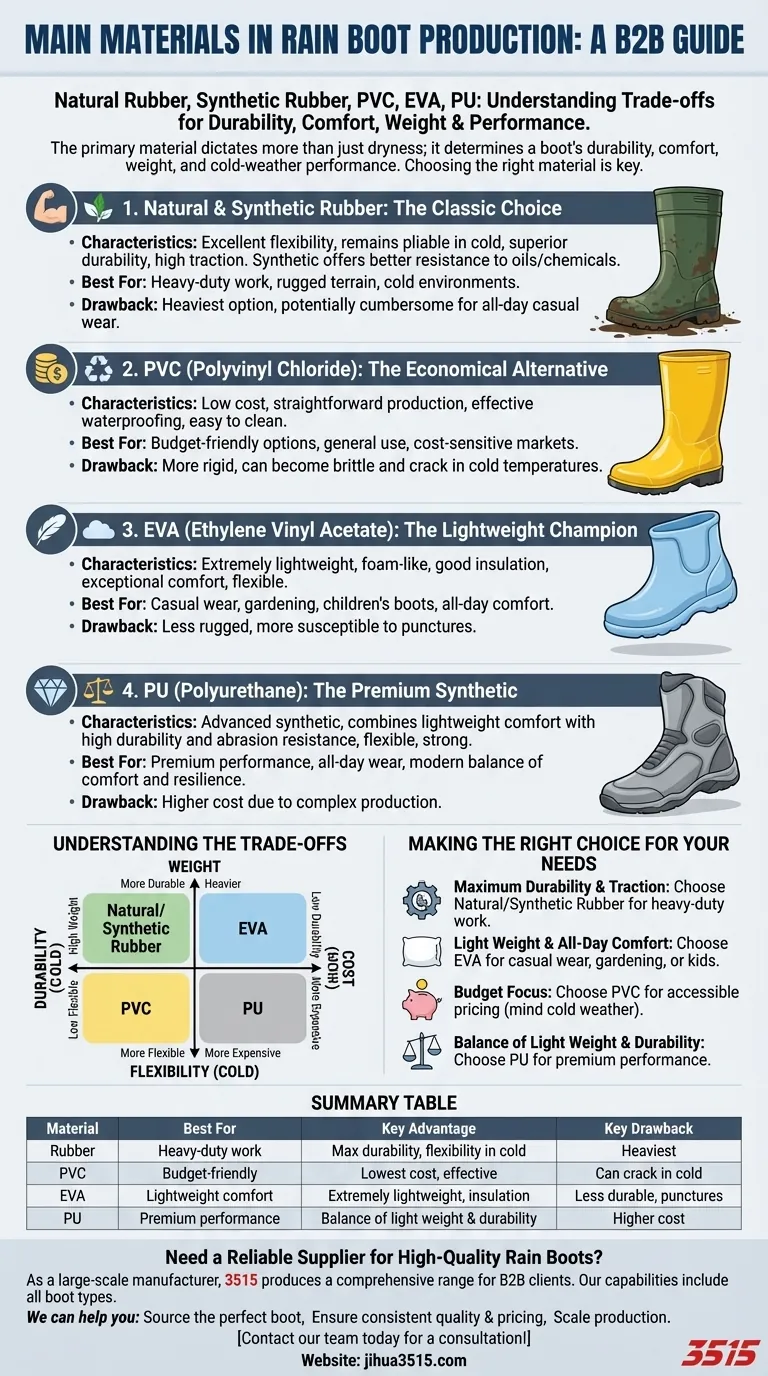

The Core Materials: A Detailed Comparison

Each material used in rain boot construction serves the primary purpose of waterproofing, but they achieve this with different characteristics. The choice of material directly impacts the final product's feel, longevity, and ideal use case.

Natural and Synthetic Rubber: The Classic Choice

Natural rubber is the original material for modern waterproof boots, prized for its inherent flexibility and durability. It remains pliable in cold temperatures and provides excellent traction.

Synthetic rubber offers similar properties, often with improved resistance to oils and chemicals. Both types create a highly resilient and completely waterproof barrier, making them ideal for heavy-duty use.

PVC (Polyvinyl Chloride): The Economical Alternative

PVC is a type of plastic that is widely used in rain boot manufacturing due to its low cost and straightforward production process. It is an effective waterproofer and is easy to clean.

However, PVC is generally more rigid than rubber. It can become stiff and even brittle in very cold temperatures, which can sometimes lead to cracking over time.

EVA (Ethylene Vinyl Acetate): The Lightweight Champion

EVA is a foam-like synthetic material, notable for being extremely lightweight. Boots made from EVA are exceptionally comfortable for all-day wear and are a popular choice for children's boots.

This material provides good insulation and flexibility. The main drawback of its lightweight nature is a reduction in ruggedness; it is more susceptible to punctures than rubber or PVC.

PU (Polyurethane): The Premium Synthetic

Polyurethane (PU) is a more advanced synthetic that combines the light weight of EVA with greater durability and resistance to abrasion. It is a high-performance material that remains flexible and strong.

PU boots are often more expensive, but they represent a modern balance of comfort and resilience, making them a premium alternative to traditional rubber.

Understanding the Trade-offs

Choosing a rain boot involves balancing competing factors. What you gain in one area, such as low cost, you may sacrifice in another, such as cold-weather performance.

Durability vs. Weight

Natural rubber is the gold standard for durability but is also the heaviest option. This makes it perfect for demanding tasks but potentially cumbersome for casual, all-day wear.

In contrast, EVA is on the opposite end of the spectrum—incredibly light but less resistant to punctures and rough use. PVC and PU sit in the middle, offering a balance between the two extremes.

Flexibility and Cold Weather Performance

A material's reaction to cold is a critical factor. Natural rubber excels here, staying flexible when temperatures drop.

PVC is the most vulnerable to cold, becoming stiff and losing its comfortable flex. This can make walking feel unnatural and increases the risk of the material cracking.

Cost and Environmental Impact

PVC is typically the most affordable material, making it a common choice for budget-friendly boots. EVA is also relatively inexpensive.

Natural rubber and PU are usually found in higher-priced boots, reflecting their more complex production and superior performance characteristics.

Making the Right Choice for Your Needs

Your ideal rain boot material depends entirely on how you intend to use it. Consider your primary goal to make an informed decision.

- If your primary focus is maximum durability and traction: Natural or synthetic rubber is the superior choice for heavy-duty work or rugged terrain.

- If your primary focus is light weight and all-day comfort: Look for boots made from EVA, which are ideal for casual wear, gardening, or for children.

- If your primary focus is budget: PVC offers effective waterproofing at the most accessible price point, but be mindful of its performance in cold weather.

- If your primary focus is a balance of light weight and durability: Polyurethane (PU) boots provide a modern, high-performance alternative to traditional rubber.

Understanding these material differences empowers you to select rain boots that perfectly match your specific requirements.

Summary Table:

| Material | Best For | Key Advantage | Key Drawback |

|---|---|---|---|

| Natural/Synthetic Rubber | Heavy-duty work, rugged terrain | Maximum durability, flexibility in cold | Heaviest option |

| PVC (Polyvinyl Chloride) | Budget-friendly, general use | Lowest cost, effective waterproofing | Can crack in cold weather |

| EVA (Ethylene Vinyl Acetate) | Lightweight comfort, casual wear, kids | Extremely lightweight, good insulation | Less durable, prone to punctures |

| PU (Polyurethane) | Premium performance, all-day wear | Excellent balance of light weight & durability | Higher cost |

Need a Reliable Supplier for High-Quality Rain Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of rain boots, from durable rubber work boots to lightweight EVA casual styles.

We can help you:

- Source the perfect boot for your target market and climate.

- Ensure consistent quality and competitive pricing.

- Scale production to meet your volume requirements.

Let's discuss your next order. Contact our team today for a consultation!

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What are the distinctive features of rain boots? Unmatched Waterproof Protection Explained

- What are rain boots made of? Discover the best materials for ultimate waterproof protection.

- How do the heights of rain boots and snow boots compare? A Guide to Weather-Ready Footwear

- What are the liner materials for rain boots? Cotton vs. Blends for Comfort & Durability

- What factors should be considered when choosing rain boots? Find the Perfect Boot for Your Needs