The primary disadvantages of composite toe boots are their increased bulk and lower ultimate impact resistance compared to steel toe boots. While they are certified to meet the same official safety standards, the non-metallic materials used in composite toes must be thicker to provide the required protection, resulting in a larger toe cap. For environments with extreme risks of falling objects, steel offers a higher margin of safety against crushing forces.

The core decision between composite and steel toe boots is a direct trade-off. Composite toes sacrifice the absolute maximum impact protection and slimmer profile of steel in exchange for significant gains in weight, comfort, and protection from electrical and thermal hazards.

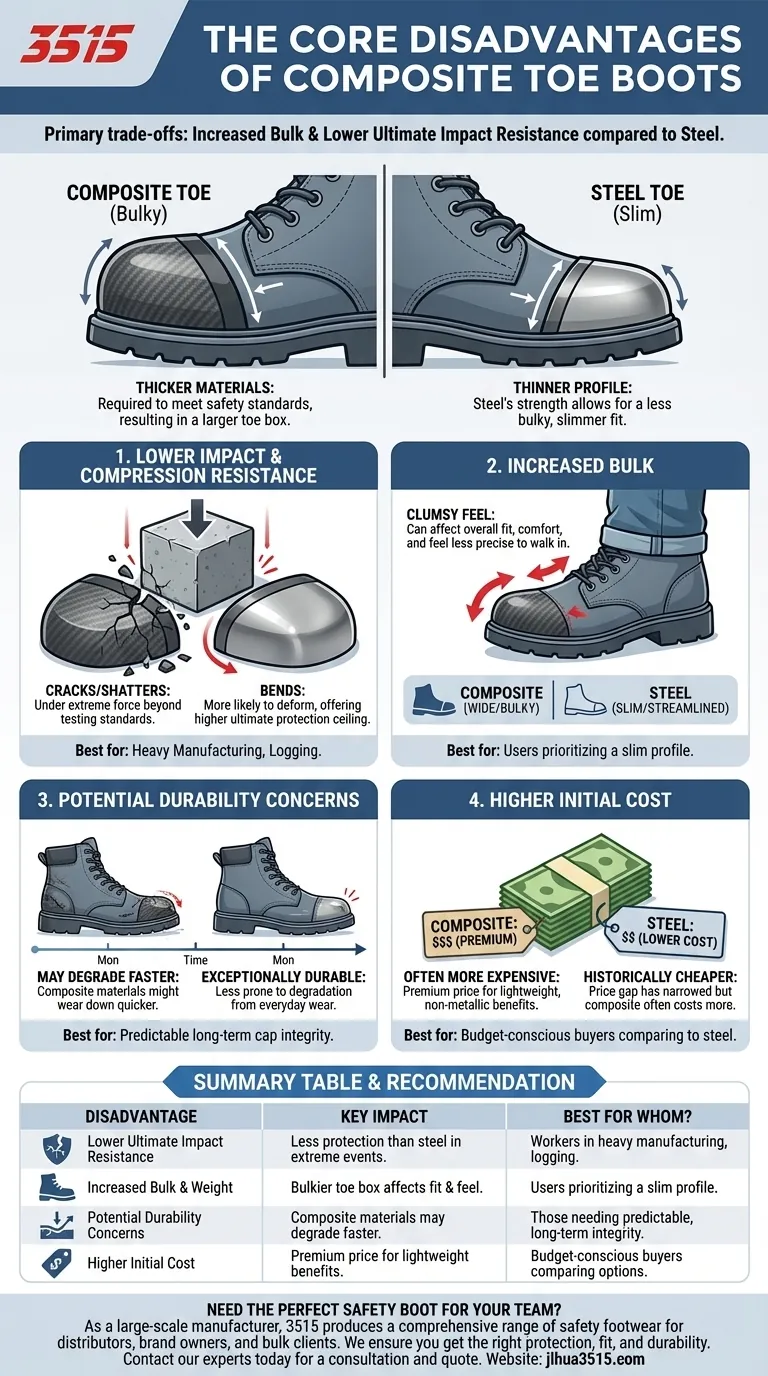

The Core Limitations of Composite Toes

While composite toe boots offer many modern advantages, it's crucial to understand their specific limitations before deciding if they are right for your work environment.

Lower Impact & Compression Resistance

While composite toe boots meet all required OSHA and ASTM safety standards, they do not offer the same level of ultimate protection as steel. In the event of an extreme impact or compression event that exceeds testing standards, steel is more likely to bend, whereas a composite cap is more likely to crack or shatter.

For most job sites, this difference is negligible. However, in high-risk industries like heavy manufacturing or logging, steel provides a superior safety ceiling.

Increased Bulk

To achieve the required safety rating, the materials used in composite toe caps—such as carbon fiber, Kevlar, or plastic—must be thicker than a comparable steel cap. This results in a bulkier, more bulbous toe box.

This can affect the overall fit and comfort of the boot, and may feel clumsy to those accustomed to the slimmer profile of steel or alloy toe boots.

Potential Durability Concerns

Some evidence suggests that the composite materials may wear down faster than steel over the long term. While a quality boot will last for years, the integrity of the protective cap itself is paramount.

Steel is exceptionally durable and less prone to degradation from everyday wear and tear, offering a more predictable lifespan for the protective element of the boot.

Higher Initial Cost

Historically, composite toe boots have been more expensive than their steel counterparts. While this price gap has narrowed as the technology becomes more widespread, you can often expect to pay a premium for the lightweight and non-metallic benefits.

Understanding the Trade-offs: Composite vs. Steel

Choosing the right safety boot isn't about finding the "best" material, but the right material for your specific job and its associated risks.

When to Choose Composite

The advantages of composite toes are clear and significant. Their lighter weight reduces foot fatigue over long shifts, making them ideal for workers who are constantly on the move.

Because they don't conduct electricity, they are the standard choice for electricians and engineers. They also provide superior thermal insulation, keeping feet warmer in the cold and cooler in the heat, and will not set off metal detectors.

When to Choose Steel

Steel remains the gold standard for maximum impact and compression protection. Its ability to withstand extreme force makes it the most reliable choice for environments where the risk of heavy falling or rolling objects is high.

Furthermore, the strength of steel allows for a thinner toe cap, resulting in a less bulky boot that many users prefer for its fit and appearance.

Making the Right Choice for Your Work Environment

Your daily tasks and environment should be the deciding factors. Use these guidelines to make a clear decision.

- If your primary risk is severe impact or compression: Choose steel toe boots for their superior strength and durability in high-risk environments like construction or heavy industry.

- If you are an electrician or work in a metal-free facility: Composite toe boots are the essential choice due to their non-conductive and non-metallic properties.

- If your primary focus is all-day comfort and mobility: Choose composite toe boots to benefit from their lighter weight, which significantly reduces fatigue when walking long distances.

- If you work in extreme hot or cold temperatures: Choose composite toe boots for their superior thermal insulation, which prevents the transfer of heat and cold to your feet.

Ultimately, understanding these core differences empowers you to select the safety footwear that truly matches your specific daily risks and demands.

Summary Table:

| Disadvantage | Key Impact | Best For Whom? |

|---|---|---|

| Lower Ultimate Impact Resistance | Less protection than steel in extreme crushing events | Workers in heavy manufacturing, logging |

| Increased Bulk & Weight | Bulkier toe box can affect fit and feel clumsy | Users prioritizing a slim profile and precise fit |

| Potential Durability Concerns | Composite materials may degrade faster than steel over time | Those needing predictable, long-term cap integrity |

| Higher Initial Cost | Often a premium price for lightweight, non-metallic benefits | Budget-conscious buyers comparing to steel toe options |

Need the Perfect Safety Boot for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of composite and steel toe boots, ensuring you get the right protection, fit, and durability for your specific work environment.

Let us help you navigate the trade-offs and equip your workforce with optimal safety footwear. Contact our experts today for a consultation and quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Durable Moc-Toe Wedge Work Boots | Wholesale Manufacturing for Brands

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- Is safety-toe as good as steel toe? Choose the Right Protection for Your Job

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture