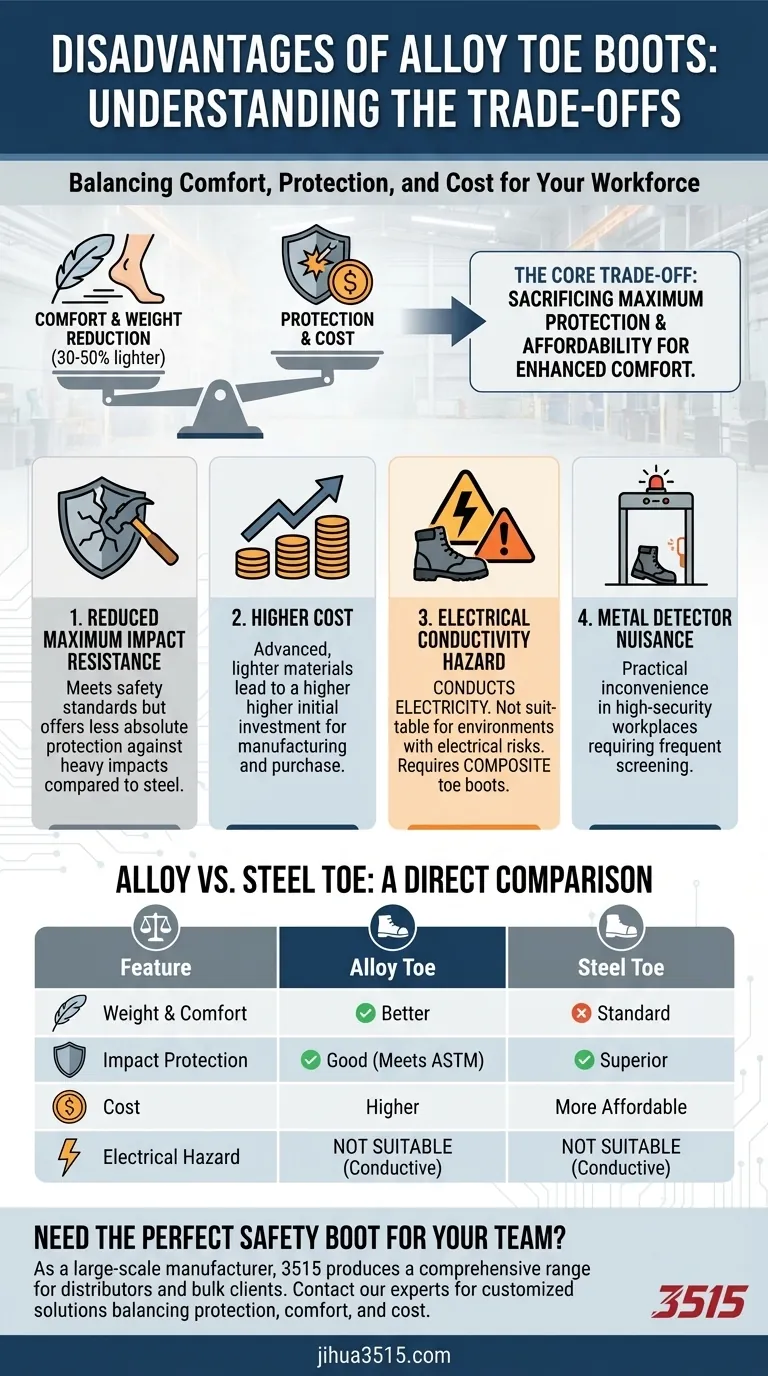

First, the direct answer: The main disadvantages of alloy toe boots are their cost (they're generally more expensive than steel toe boots), slightly reduced impact resistance compared to steel, and their electrical conductivity.

The Core Takeaway: Alloy toe boots offer a trade-off: increased comfort and reduced weight for a slight decrease in impact protection and an increase in cost, compared to traditional steel toe boots. They are not suitable for electrical hazard environments.

To address the underlying question, "Which boot is right for me?" I need to dive deeper. The user isn't just asking about disadvantages; they're trying to choose the best safety boot for their needs. This calls for a comparison with the main alternative: steel toes.

Alloy toes are all about balancing protection and comfort. They often weigh 30-50% less than steel toes, leading to less fatigue over long workdays, and tend to provide more toe room. However, their lighter materials (typically aluminum alloys or titanium alloys) are the source of their disadvantages. These materials are inherently more expensive and, while meeting safety standards, are not as robust against impacts as steel.

Here's a breakdown of the trade-offs:

- Reduced Impact Resistance: While alloy toes do meet the required safety standards, steel toes offer a higher level of protection against heavy impacts.

- Higher Cost: The advanced materials used in alloy toes make them more expensive to manufacture than steel toe boots.

- Electrical Conductivity: Crucially, both alloy and steel toes are conductive. This means neither type is suitable for environments with electrical hazards. Composite toe boots are the correct choice there.

- Metal Detector Nuisance: Alloy boots can trigger metal detectors, which might be a practical issue in some workplaces.

Now, let's directly compare alloy to steel:

- Weight and Comfort: Alloy toes are the clear winner here. The lighter weight is a significant advantage for comfort and reducing foot fatigue.

- Maximum Protection: Steel toes offer the highest level of impact resistance. If maximum protection is the primary goal, steel is the better choice.

- Cost: Steel toe boots are generally more affordable.

Ultimately, the best choice depends on the user's specific needs and priorities:

- If your primary focus is maximum protection and budget: Steel toe boots are the most cost-effective option and offer superior impact resistance.

- If all-day comfort and reduced fatigue are paramount: Alloy toe boots provide a significant advantage, assuming the reduced impact protection is sufficient for your work.

- If you work in an environment with electrical hazards: Neither alloy nor steel is appropriate. You must choose boots with composite toes.

It's about making an informed decision that aligns with the specific risks and needs of the job. To be direct, the primary disadvantages of alloy toe boots are their higher cost, slightly lower impact resistance compared to steel, and their electrical conductivity, which makes them unsuitable for certain work environments. They also tend to set off metal detectors, which can be a practical inconvenience.

The core issue is one of trade-offs. Alloy toe boots sacrifice a degree of maximum protection and affordability in exchange for a significant improvement in comfort and a reduction in weight compared to traditional steel toes.

Why Alloy Toes Exist: The Comfort Problem

For decades, the steel toe was the undisputed standard for safety footwear. However, its significant weight and bulkiness created a deep need for a more comfortable alternative for professionals who spend all day on their feet.

The Innovation of Lighter Metals

Alloy toes were engineered to solve this problem. They are typically made from lightweight materials like aluminum and titanium.

This construction makes alloy toe caps 30% to 50% lighter than their steel counterparts.

The Benefit of a Thinner Profile

The materials used in alloy caps are strong enough that the cap itself can be thinner than a steel one. This seemingly small difference creates noticeably more room in the toe box, reducing rubbing and increasing overall comfort for long shifts.

Understanding the Trade-offs of Alloy Toes

Choosing an alloy toe boot means accepting a specific set of compromises. Understanding these is critical to making an informed decision.

Reduced Impact Resistance

While all safety boots must meet specific ASTM standards for impact and compression, steel offers the highest level of absolute protection. For environments with extreme risks from heavy machinery or falling objects, steel remains the top performer in pure strength.

Higher Cost

The advanced, lighter materials used in alloy toes are more expensive to source and manufacture than simple steel. This cost is passed directly to the consumer, making alloy toe boots a more significant initial investment.

Critical Safety: Electrical Conductivity

Like steel, aluminum and titanium alloys are metals and will conduct electricity. This makes alloy toe boots completely unsuitable for electricians or anyone working in an environment with a risk of electrical hazards.

A Practical Inconvenience

Because they are made of metal, alloy toe boots will set off metal detectors. This can be a daily nuisance in high-security workplaces that require frequent screening.

Alloy Toe vs. Steel Toe: A Direct Comparison

Your decision ultimately comes down to comparing the two dominant metal-based safety toes and their specific attributes.

Weight and Comfort: Alloy's Clear Advantage

For all-day wear, alloy is the superior choice. The significant weight reduction lessens fatigue, while the thinner cap provides more toe room and a more comfortable fit.

Maximum Protection: Steel's Core Strength

If your work involves the risk of severe impact from heavy lifting or machinery, steel's superior strength and durability provide the maximum possible protection.

Temperature Conduction: A Shared Flaw

Both steel and alloy are metals and will conduct ambient temperatures. In very hot or cold environments, the toe cap can become uncomfortable, a problem that non-metallic composite toes solve.

Making the Right Choice for Your Goal

Your specific work environment and priorities should dictate your choice.

- If your primary focus is maximum protection and a lower budget: A steel toe boot provides the highest level of impact resistance at a more cost-effective price point.

- If your primary focus is all-day comfort and reducing fatigue: An alloy toe boot is the superior choice, offering certified protection with significantly less weight.

- If your primary focus is safety from electrical hazards: You must choose a non-metallic composite toe boot, as both alloy and steel are conductive.

Ultimately, understanding these material differences empowers you to select the tool that best serves your safety and comfort.

Summary Table:

| Feature | Alloy Toe | Steel Toe |

|---|---|---|

| Weight | Lighter (30-50% less) | Heavier |

| Impact Protection | Good (Meets ASTM) | Superior |

| Cost | Higher | More Affordable |

| Electrical Hazard | Not Suitable (Conductive) | Not Suitable (Conductive) |

| Comfort & Toe Room | Better | Standard |

Need the perfect safety boot for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of alloy, steel, and composite toe boots for distributors, brand owners, and bulk clients. We can help you select or customize the ideal footwear that balances protection, comfort, and cost for your specific work environment.

Contact our experts today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What are the protective functions of industrial safety boots in sugar factory clarification stations? Thermal & Slip Experts

- What primary protective functions do industrial safety shoes provide? Maximize Safety in Heavy Machinery Maintenance

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- What is the core function of professional safety boots within a construction Health and Safety (H&S) management system? Beyond Protection: Boost Safety & Productivity

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear