The primary types of safety toe caps are steel, composite, and alloy. Each material is engineered to meet standardized safety ratings for impact and compression, but they offer distinct advantages in terms of weight, conductivity, and comfort. While steel is the traditional standard for heavy-duty protection, modern composite and alloy alternatives provide comparable safety with added benefits for specific work environments.

The core decision is not simply about safety, as all certified caps are protective. Instead, it's a strategic trade-off between the absolute strength of steel, the lightweight and non-conductive nature of composite, and the balanced performance of alloy.

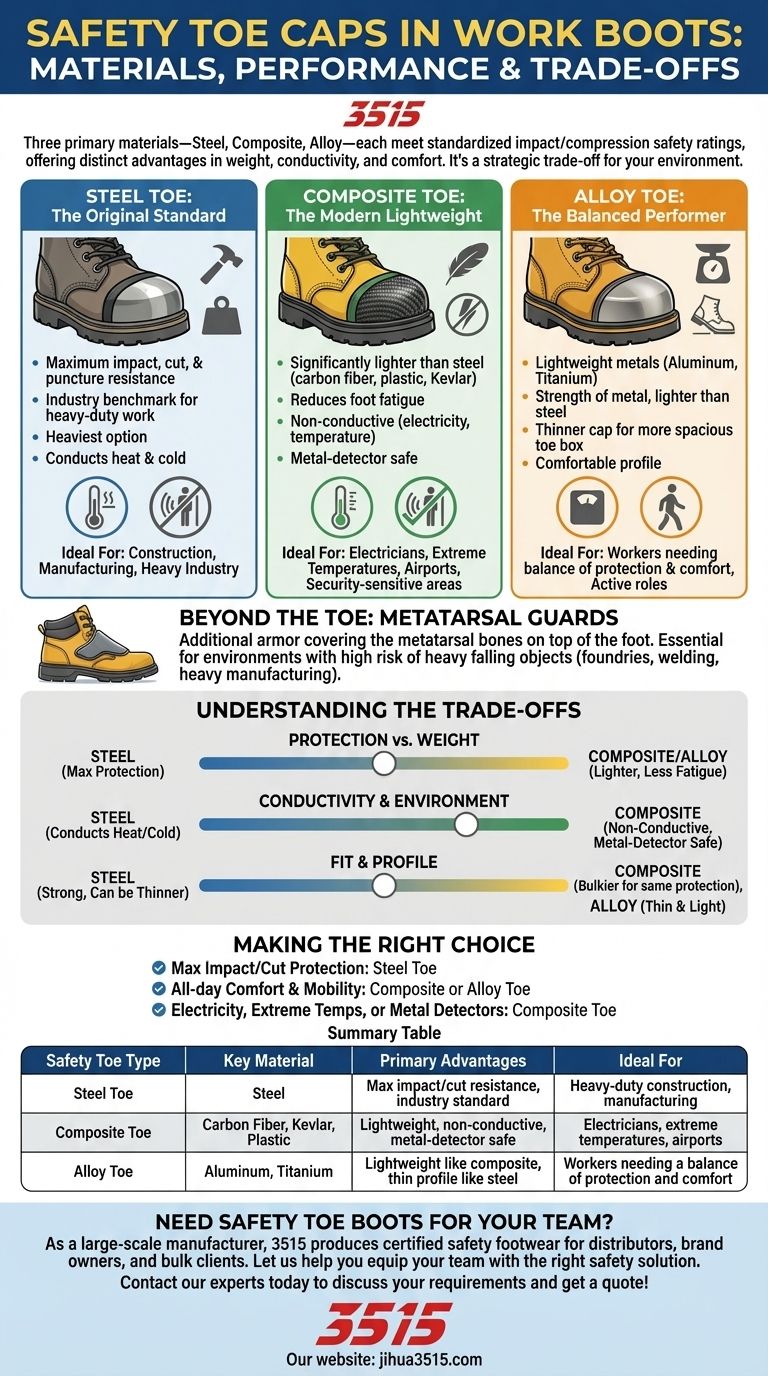

The Three Core Types of Safety Toes

Each safety toe material is designed to shield your toes from injury, primarily from falling objects or compression from heavy machinery. The choice of material directly impacts the boot's weight, fit, and suitability for your environment.

Steel Toe: The Original Standard

Steel is the traditional material for safety toes and is known for providing the highest level of resistance against impact, cuts, and punctures. It is the benchmark against which other materials are often measured.

These caps are tested to withstand significant force, often a 200-joule impact, making them the default choice for heavy-duty work like construction or manufacturing. However, they are the heaviest option and will conduct heat and cold.

Composite Toe: The Modern Lightweight

Composite toes are crafted from non-metallic materials like carbon fiber, plastic, or Kevlar. Their primary advantage is being significantly lighter than steel, which reduces foot fatigue over a long day.

Because they contain no metal, composite toe boots will not set off metal detectors. They are also poor conductors of electricity and temperature, making them ideal for electricians or those working in extreme hot or cold conditions.

Alloy Toe: The Balanced Performer

Alloy toes are made from lightweight metals such as aluminum or titanium. They provide the strength and impact resistance expected from metal protection but in a much lighter package than steel.

This technology often allows for a thinner cap, which can result in a more spacious and comfortable toe box compared to the bulkier designs of some steel or composite toes.

Beyond the Toe: Understanding Metatarsal Guards

While a toe cap protects the toes, some jobs require an even higher level of protection that extends further up the foot.

What Is a Metatarsal Guard?

A metatarsal guard is an additional piece of armor that covers the top of your foot—the metatarsal bones. It is designed to protect this vulnerable area from severe impact from heavy falling objects.

When Is It Necessary?

This feature is essential for workers in particularly hazardous environments, such as foundries, welding, or heavy manufacturing, where the risk of something heavy crushing the entire top of the foot is high.

Understanding the Trade-offs

Choosing the right toe cap requires balancing protection with the practical demands of your workday. No single material is universally "best."

Protection vs. Weight

Steel offers the ultimate peace of mind for puncture and side-compression resistance. However, the weight savings from alloy and composite boots can dramatically increase comfort and reduce fatigue, a critical factor for anyone who walks or stands all day.

Conductivity and Environment

If you work in extreme cold or heat, the thermal conductivity of a steel toe can be a significant source of discomfort. Composite toes completely solve this issue. Likewise, if you must pass through metal detectors frequently, composite is the only logical choice.

Fit and Profile

Because steel is so strong, the cap can be made relatively thin. Composite caps sometimes need to be bulkier to provide the same level of impact protection, which can make the boot feel larger. Alloy toes often strike a good balance, offering a thin profile similar to steel but with less weight.

Making the Right Choice for Your Work

Your specific job function and environment should be the final determining factors in your decision.

- If your primary focus is maximum impact and cut protection: Steel toe remains the industry benchmark for heavy construction and industrial sites.

- If your primary focus is all-day comfort and mobility: Composite or alloy toes offer significant weight reduction without compromising certified safety.

- If you work around electricity, in extreme temperatures, or pass through metal detectors: Composite toe is the only practical choice.

Ultimately, understanding these materials empowers you to select a boot that protects your feet without compromising your performance.

Summary Table:

| Safety Toe Type | Key Material | Primary Advantages | Ideal For |

|---|---|---|---|

| Steel Toe | Steel | Maximum impact/cut resistance, industry standard | Heavy-duty construction, manufacturing |

| Composite Toe | Carbon Fiber, Kevlar, Plastic | Lightweight, non-conductive, metal-detector safe | Electricians, extreme temperatures, airports |

| Alloy Toe | Aluminum, Titanium | Lightweight like composite, thin profile like steel | Workers needing a balance of protection and comfort |

Need Safety Toe Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Whether your workforce requires the ultimate protection of steel toes or the lightweight comfort of composite caps, we have the production capabilities and expertise to meet your needs.

Let us help you equip your team with the right safety solution.

Contact our experts today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- What are the two key ASTM International documents governing safety footwear? A Guide to F2413 & F2412

- Why is a fuzzy logic model more effective for professional footwear assets? Modeling Gradual Wear with Precision

- What are the main stages involved in safety shoes manufacturing? A Guide to Durable, Protective Footwear

- What role do industrial safety shoes play in OHS management? Enhancing Workforce Protection and Safety Culture

- What are the technical benefits of a stable shoe model design in high-intensity medical environments? Boost Safety

- What are the advantages of leather as a material for motorcycle boots? Unmatched Safety & Long-Term Comfort

- What are the primary protective functions of industrial-grade safety shoes in underground mining? Secure Your Workers.

- What are the primary functions of industrial-grade safety shoes? Crucial Protection for Construction Safety