At its core, safety footwear is categorized by official protection classes that define its specific safety features against workplace hazards. These classes, such as SB, S1, S1P, S2, and S3, provide a standardized way to understand what level of protection a shoe offers, moving far beyond simple distinctions like "steel-toe boots."

The most critical step in choosing safety footwear is not to look for a specific style, but to identify the required protection class for your work environment. This class dictates the shoe's fundamental safety features, from toe protection to penetration and water resistance.

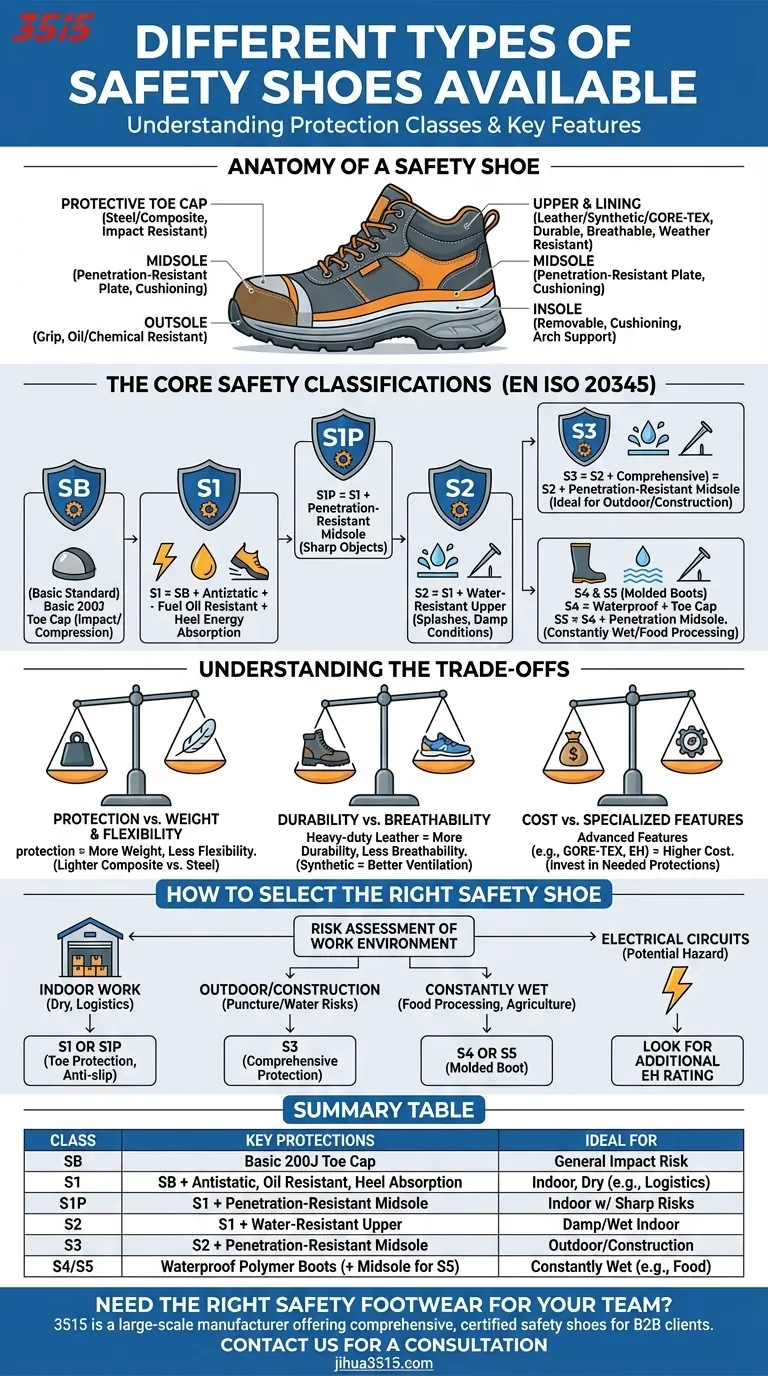

Understanding the Anatomy of a Safety Shoe

Before deciphering the protection codes, it's essential to understand that a safety shoe is an integrated system. Each component is engineered to work together to provide comprehensive protection.

The Protective Toe Cap

This is the most well-known feature. It protects the toes from impact and compression forces. Modern safety shoes use either traditional steel caps or lighter composite caps made from materials like carbon fiber or plastic.

The Upper and Lining

The upper is the main body of the shoe above the sole. Its material—be it leather, synthetic fabrics, or waterproof membranes like GORE-TEX—determines the shoe's durability, breathability, and resistance to elements.

The Midsole and Outsole

The outsole is the part that contacts the ground, designed for grip and resistance to oil or chemicals. The midsole, located above it, provides cushioning and can contain a penetration-resistant plate to protect against sharp objects like nails.

The Insole and Footbed

The insole, or footbed, is the removable layer your foot rests on. It provides cushioning and arch support, which is critical for comfort during long shifts. These can often be replaced to accommodate different arch types (low, medium, or high).

The Core Safety Classifications (The "S" Codes)

The European EN ISO 20345 standard is the most common system for classifying safety footwear. The ratings are cumulative, meaning each level includes all the protections of the levels before it.

SB - The Basic Standard

This is the most basic level of protection. SB shoes feature a protective toe cap rated for 200 joules of impact. They do not necessarily have any other protective features.

S1 - Adding Foundational Workplace Protections

An S1 shoe includes the basic SB toe cap plus additional features for indoor work. It is antistatic, resistant to fuel oil, and has energy absorption in the heel area for added comfort.

S1P - Including Penetration Resistance

The S1P rating has all the features of an S1 shoe but adds a puncture-resistant midsole. This is crucial for environments where stepping on sharp objects is a risk.

S2 - Incorporating Water Resistance

An S2 shoe builds on the S1 standard by adding water resistance for the upper material. This keeps the wearer's feet dry from splashes or in damp working conditions.

S3 - The Comprehensive Protection Standard

S3 is one of the most common and comprehensive ratings. It combines all the features of an S2 shoe (water resistance) with the penetration-resistant midsole of an S1P shoe. This makes it ideal for most outdoor and construction work.

A Note on S4 & S5

The S4 and S5 classifications are reserved for fully molded polymer or rubber footwear, like Wellington boots. S4 is waterproof with a safety toe, while S5 adds a penetration-resistant midsole.

Understanding the Trade-offs

Choosing safety footwear involves balancing competing factors. Understanding these trade-offs is key to selecting a shoe that is both safe and practical for daily use.

Protection vs. Weight and Flexibility

Higher levels of protection, such as steel midsoles and robust uppers, inevitably add weight and reduce flexibility. For roles requiring constant movement, a lighter composite toe (instead of steel) can significantly reduce fatigue.

Durability vs. Breathability

Heavy-duty leather uppers offer maximum durability but can be less breathable, leading to discomfort in hot environments. Modern synthetic materials may offer better breathability but might not withstand the same level of abrasion.

Cost vs. Specialized Features

Features like advanced waterproofing (GORE-TEX), superior slip resistance, or electrical hazard (EH) ratings come at a higher cost. It's crucial to invest in the features your specific job requires and avoid paying for protections you don't need.

How to Select the Right Safety Shoe for Your Role

Your choice should be dictated by a risk assessment of your specific work environment. Use the protection classes as your primary guide.

- If your primary focus is indoor work in dry conditions (e.g., logistics, assembly): An S1 or S1P shoe provides the necessary toe protection and anti-slip properties without unnecessary bulk.

- If your primary focus is outdoor construction or jobs with puncture and water risks: S3 is the non-negotiable standard, offering comprehensive protection from impact, penetration, and wet conditions.

- If your primary focus is working in constantly wet environments (e.g., food processing, agriculture): An S4 or S5 molded boot is required to ensure your feet stay completely dry and protected.

- If your primary focus is working near potential live electrical circuits: You must look for a specific Electrical Hazard (EH) rating in addition to the appropriate "S" class.

By understanding these classifications, you can move beyond guesswork and choose the precise protection you need to work safely and confidently.

Summary Table:

| Safety Class | Key Protections | Ideal For |

|---|---|---|

| SB | Basic 200J toe cap | General environments with impact risk |

| S1 | SB + Antistatic, fuel oil resistance, heel absorption | Indoor, dry work (e.g., logistics, assembly) |

| S1P | S1 + Penetration-resistant midsole | Indoor work with sharp object risk |

| S2 | S1 + Water-resistant upper | Damp or wet indoor conditions |

| S3 | S2 + Penetration-resistant midsole | Outdoor/construction (comprehensive protection) |

| S4/S5 | Waterproof polymer/rubber boots (S5 adds midsole) | Constantly wet environments (e.g., food processing) |

Need the right safety footwear for your team or brand?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. We offer production capabilities for all types of safety shoes and boots, ensuring you get the precise protection, comfort, and durability your workforce needs.

Contact us today for a consultation and let us help you equip your team with the right safety solution.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Wheat Nubuck Safety Shoes for Bulk Distribution

People Also Ask

- Why are industrial-grade safety shoes mandatory in metallurgical workshops? Essential Protection for Extreme Environments

- Why is it mandatory to wear safety shoes with steel toe protection during metal loading? Prevent Crushing Injuries

- Why is compliance with safety standards such as PN EN ISO 20347:2012 critical? Ensure Certified Workplace Protection

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now

- Why does the material performance of professional slip-resistant shoes offer superior safety? Hardware vs. Behavior