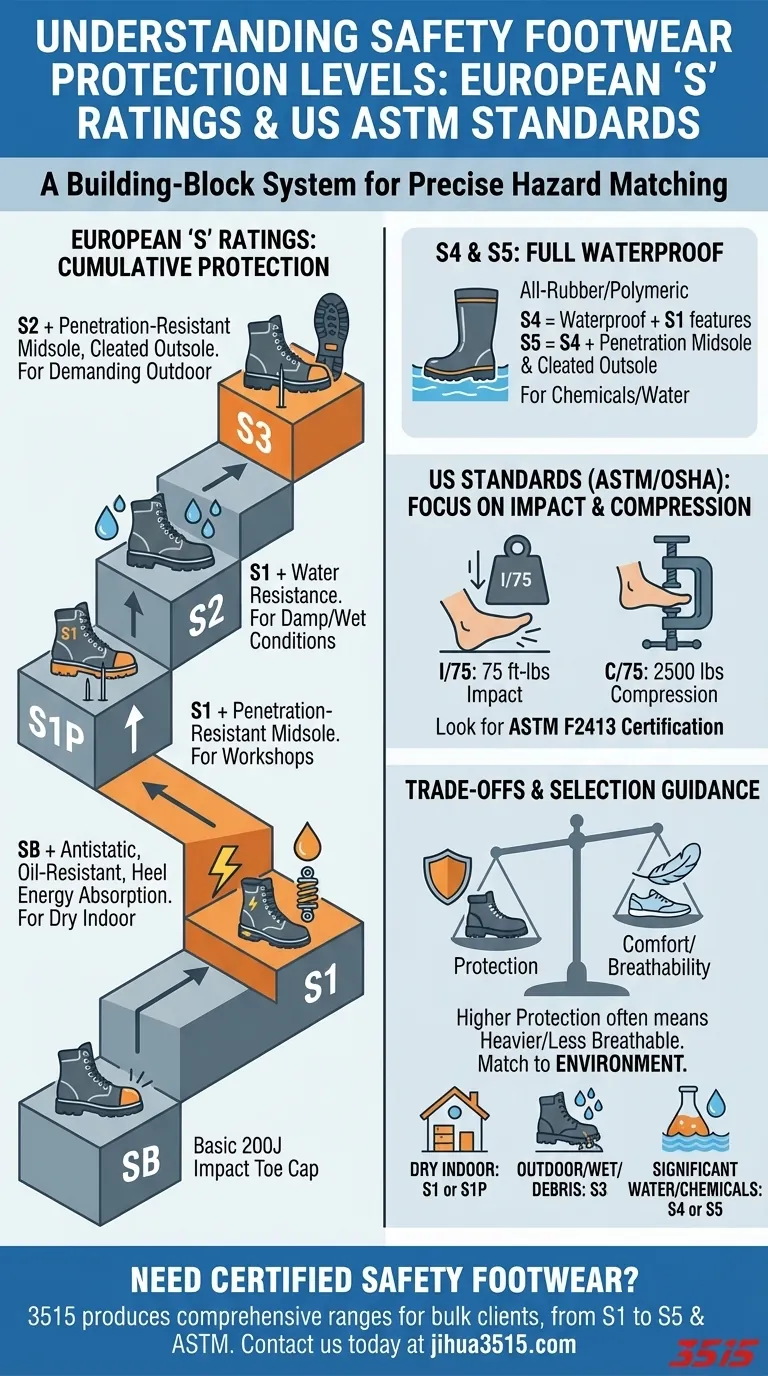

At its core, safety footwear protection is defined by a series of cumulative ratings. The most common system, prevalent in Europe, uses 'S' codes. The foundational level is SB, which mandates a protective toe cap. From there, S1 adds features for dry, indoor environments like antistatic properties; S1P adds puncture resistance to S1; S2 adds water resistance to S1; and S3 combines the features of S2 with puncture resistance, making it suitable for demanding outdoor or wet environments.

The crucial takeaway is that safety footwear ratings are not arbitrary codes; they are a building-block system. Each successive level (from SB to S1 to S3) adds specific protective features, allowing you to precisely match the footwear to the known hazards of your work environment.

Breaking Down the 'S' Ratings: A Feature-by-Feature Guide

The European Standard EN ISO 20345 is the most widely recognized system for classifying safety footwear. It creates a clear hierarchy of protection that is easy to understand once you know the basics.

SB: The Foundation of Safety

This is the most basic level of safety footwear. Any boot or shoe labeled SB has a toe cap that provides protection against a 200-joule impact. This is the non-negotiable starting point for all safety ratings.

S1: Adding Indoor Workplace Essentials

An S1 rating includes all the features of SB and adds three critical elements for indoor work:

- Antistatic properties to dissipate static electricity.

- Fuel and oil resistant outsole.

- Energy absorption in the heel region to reduce impact.

S1P: Protection From Below

The S1P rating is simple: it is an S1 shoe that also includes a penetration-resistant midsole. This protects the foot from sharp objects like nails or screws piercing through the sole, making it ideal for workshops or sites with floor debris.

S2: Introducing Water Resistance

An S2 shoe contains all the features of the S1 rating but adds protection against water penetration and absorption. This does not mean fully waterproof, but it is suitable for working in damp or wet conditions.

S3: The All-Rounder for Demanding Environments

The S3 rating is one of the most comprehensive and common. It combines the features of an S2 shoe (including water resistance) with the penetration-resistant midsole found in S1P, plus a cleated outsole for enhanced grip.

S4 & S5: For Full Waterproof Protection

These ratings apply to all-rubber or all-polymeric footwear, like Wellington boots. S4 boots are fully waterproof and have all S1 features. S5 is the highest level, adding a penetration-resistant midsole and cleated outsole to the S4 boot.

How US Standards (ASTM/OSHA) Differ

While many principles overlap, the United States' system, governed by OSHA and referencing ASTM standards, labels footwear differently.

The Focus on Impact and Compression

Instead of 'S' ratings, ASTM-compliant footwear uses specific line-item codes. The most critical are for impact (I) and compression (C). The highest rating, and the one typically required by OSHA, is 75, which protects against 2,500 pounds of compression and 75 foot-pounds of impact.

Key OSHA Requirements

OSHA mandates that protective footwear in hazardous environments must be certified to ASTM standards. Required features generally include a leather upper, non-skid soles, oil resistance, and built-in toe caps with that I/75 and C/75 rating.

The Importance of Certification

Always look for footwear explicitly marked as compliant with ASTM F2413. This standard outlines the performance requirements, while ASTM F2412 defines the testing methods, ensuring the ratings are reliable and consistent.

Understanding the Trade-offs

Choosing the right safety boot isn't just about picking the highest number. Over-specifying can be as problematic as under-specifying.

Protection vs. Comfort

Higher protection levels, especially those with penetration-resistant midsoles and water-resistant materials, can result in heavier, stiffer, and less breathable footwear. This can increase fatigue over a long shift.

The Environmental Mismatch

Wearing an S3 water-resistant boot in a hot, dry indoor warehouse can lead to significant discomfort and sweaty feet. Conversely, wearing a more breathable S1 boot on a construction site exposes you to unnecessary risks from water and punctures.

Beyond the Basics

Remember that the 'S' ratings cover the most common hazards, but not all of them. Specialized risks, such as electrical hazards (EH) or chainsaw cuts, require footwear with specific additional certifications beyond the S3 or S5 level.

Making the Right Choice for Your Goal

Your specific work environment is the only factor that should determine your choice. Use the hazard assessment of your workplace as your guide.

- If your primary focus is indoor work in a dry environment with impact risk (e.g., logistics, light assembly): An S1 or S1P boot provides the necessary protection without unnecessary weight or features.

- If your primary focus is construction, outdoor work, or any environment with sharp debris and wet conditions: S3 is the most appropriate and comprehensive choice for all-around protection.

- If your primary focus is working in areas with significant standing water or chemicals (e.g., food processing, agriculture): You need the fully waterproof protection offered by S4 or S5 boots.

- If your primary focus is compliance with US OSHA regulations: You must select footwear explicitly marked as ASTM F2413 compliant with I/75 and C/75 ratings.

Ultimately, selecting the correct safety footwear is a foundational act of professional responsibility that protects you from preventable harm.

Summary Table:

| Rating | Key Features | Ideal For |

|---|---|---|

| SB | Basic 200-joule impact toe cap | Foundational protection |

| S1 | SB + antistatic, oil-resistant sole, heel energy absorption | Dry, indoor workplaces (e.g., warehouses) |

| S1P | S1 + penetration-resistant midsole | Indoor areas with sharp debris (e.g., workshops) |

| S2 | S1 + water resistance | Damp or wet indoor conditions |

| S3 | S2 + penetration-resistant midsole, cleated outsole | Demanding outdoor/construction sites |

| S4/S5 | Fully waterproof (rubber/polymeric), S1/S3 features | Significant water/chemical exposure (e.g., food processing) |

Need the right safety footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety boots and shoes for distributors, brand owners, and bulk clients. We ensure your workforce has the precise protection they need, from basic S1 to heavy-duty S5 and ASTM-compliant models, all while maintaining comfort and durability.

Contact us today for a quote and let us help you mitigate workplace risks with reliable footwear solutions.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- Are employers required to provide steel-toe rubber boots at no cost to employees? Yes, under OSHA rules.

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health