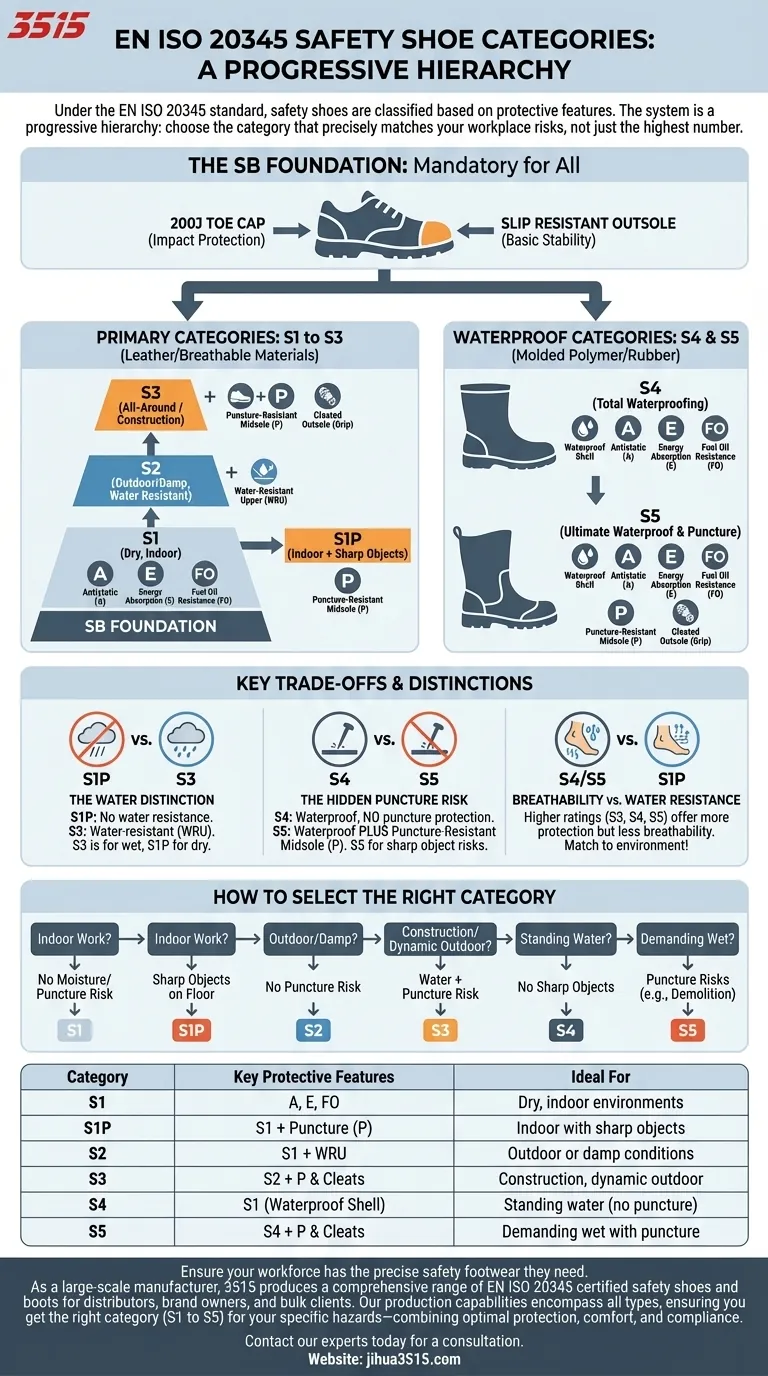

Under the EN ISO 20345 standard, safety shoes are classified into distinct categories based on the combination of protective features they provide. The primary categories are SB, SBP, S1, S1P, S2, S3, S4, and S5, with each level building upon the last to offer increasing protection against specific workplace hazards.

The core principle to understand is that the "S" rating system is a progressive hierarchy. The right choice is not always the highest number, but the one that precisely matches the specific risks—such as punctures, water, or static—present in your unique work environment.

The Foundation of All Safety Footwear

Every shoe certified under EN ISO 20345 must first meet the basic "SB" requirements. This forms the non-negotiable foundation for workplace safety.

The Mandatory Toe Cap

All certified safety footwear, regardless of its category, must include a protective toe cap. This cap is tested to withstand a 200-joule impact, protecting the wearer from heavy falling objects.

Basic Slip Resistance

The standard also mandates a minimum level of slip resistance for the outsole. This ensures a baseline of stability on common smooth or slippery surfaces.

The Primary Categories: S1 to S3

These categories typically apply to safety footwear made from leather or other breathable materials, building upon the SB foundation with additional features for more complex work environments.

S1: For Dry, Indoor Environments

An S1 shoe includes the basic SB requirements plus a fully enclosed heel, antistatic properties (A), energy absorption in the heel (E), and resistance to fuel oil (FO). They are ideal for indoor work where moisture is not a hazard.

S1P: Adding Puncture Protection

The S1P category includes all the features of S1 but adds a crucial element: a puncture-resistant midsole (P). This protects the foot from sharp objects like nails or screws penetrating from below.

S2: Introducing Water Resistance

An S2 shoe has all the protective features of an S1 but adds a water-resistant upper (WRU). This prevents water penetration and absorption, making it suitable for outdoor work or damp conditions.

S3: The All-Around Standard

S3 is often considered the most comprehensive rating for general-purpose safety footwear. It combines all the features of an S2 shoe with the puncture-resistant midsole (P) of an S1P, plus a cleated outsole for enhanced grip.

Waterproof Categories: S4 & S5

These categories are reserved for footwear made entirely from a molded polymer or rubber, such as Wellington boots. They are inherently waterproof by their construction.

S4: Total Waterproof Protection

An S4 boot provides all the features of the S1 category (antistatic, energy absorption, fuel resistance) within a fully waterproof and leak-proof molded shell. It does not have a puncture-resistant midsole.

S5: The Ultimate Waterproof Choice

The S5 rating is the highest level of protection. It includes all the features of an S4 boot but adds a puncture-resistant midsole (P) and a cleated outsole, making it the standard for the most demanding wet and hazardous environments.

Understanding the Key Trade-offs

Choosing the wrong category can lead to unnecessary cost, discomfort, or a critical gap in protection. Understanding the subtle but vital differences is key.

S1P vs. S3: The Water Distinction

The most common point of confusion is between S1P and S3. Both offer toe and midsole protection. The critical difference is that S3 is water-resistant, while S1P is not. Using an S1P boot in wet conditions will result in wet feet.

S4 vs. S5: The Hidden Puncture Risk

Both S4 and S5 boots are fully waterproof. However, an S4 boot offers no protection from sharp objects underfoot. If there is any risk of stepping on nails, glass, or rebar, an S5 is mandatory.

Breathability vs. Water Resistance

Higher-rated boots like S3, S4, and S5 offer more protection but are often less breathable. Using a waterproof S3 boot in a hot, dry warehouse can lead to significant discomfort compared to a more breathable S1P boot. The key is matching the shoe to the environment, not just picking the highest number.

How to Select the Right Category for Your Needs

A proper risk assessment is the only definitive way to choose, but these guidelines will help you make an informed decision based on your primary work environment.

- If your primary focus is indoor work with no moisture or puncture risk: An S1 shoe provides the necessary baseline protection and comfort.

- If your primary focus is indoor work with a risk of sharp objects on the floor: An S1P shoe is the correct choice, adding critical puncture resistance.

- If your primary focus is outdoor work or damp conditions without puncture risk: An S2 shoe offers the necessary water resistance to keep you dry.

- If your primary focus is construction or dynamic outdoor environments: An S3 shoe is the standard, combining water resistance, puncture protection, and a rugged outsole.

- If your primary focus is standing in water or wet concrete without sharp objects: An S4 boot provides the essential waterproof barrier.

- If your primary focus is demanding, wet environments with puncture risks (e.g., waste management, demolition): An S5 boot offers the highest level of combined protection.

By matching the specific features of each category to the real-world hazards you face, you ensure both compliance and, most importantly, your personal safety.

Summary Table:

| Category | Key Protective Features | Ideal For |

|---|---|---|

| S1 | Antistatic, Energy Absorption, Fuel Oil Resistance | Dry, indoor environments |

| S1P | S1 features + Puncture-Resistant Midsole | Indoor work with sharp objects |

| S2 | S1 features + Water-Resistant Upper | Outdoor or damp conditions |

| S3 | S2 features + Puncture-Resistant Midsole & Cleated Outsole | Construction, dynamic outdoor work |

| S4 | S1 features in a Waterproof, Leak-Proof Molded Shell | Standing water (no puncture risk) |

| S5 | S4 features + Puncture-Resistant Midsole & Cleated Outsole | Demanding wet environments with puncture risks |

Ensure your workforce has the precise safety footwear they need. As a large-scale manufacturer, 3515 produces a comprehensive range of EN ISO 20345 certified safety shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear, ensuring you get the right category (S1 to S5) for your specific hazards—combining optimal protection, comfort, and compliance.

Contact our experts today for a consultation and discover how we can support your safety and supply chain needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

People Also Ask

- What are the primary functions of Triboelectric Nanogenerators in safety shoes? Harnessing Energy & Smart Sensing

- What are the benefits and drawbacks of canvas for labour protection shoes? A Guide to Safe & Comfortable Footwear

- Why are Vibram soles considered excellent for oil-resistant safety boots? Unmatched Chemical Resilience & Grip

- What role do safety shoes play in preventing sharp object penetration? Essential Protection Explained

- What is the significance of integrating safety helmet detection with professional safety shoe management in projects?

- What is the primary function of industrial pneumatic actuator systems in safety shoe gait perturbation research?

- What core protection functions do industrial-grade Safety Shoes provide during drilling and blasting in a quarry?

- Can you wear safety shoes all day? How to Choose for Maximum Comfort & Protection