Vibram soles are widely regarded as the superior choice for oil-resistant safety footwear because they utilize high-grade vulcanized rubber engineered for maximum traction and chemical stability. Unlike standard rubber, which can swell or dissolve when exposed to petroleum-based substances, Vibram compounds maintain their structural integrity while providing the critical grip needed to prevent slips in hazardous industrial environments.

While comfort is important, the primary value of a Vibram sole in an oil-rich environment is chemical resilience. By resisting the corrosive nature of oil, these soles prevent the rapid material degradation that leads to compromised traction and premature boot failure.

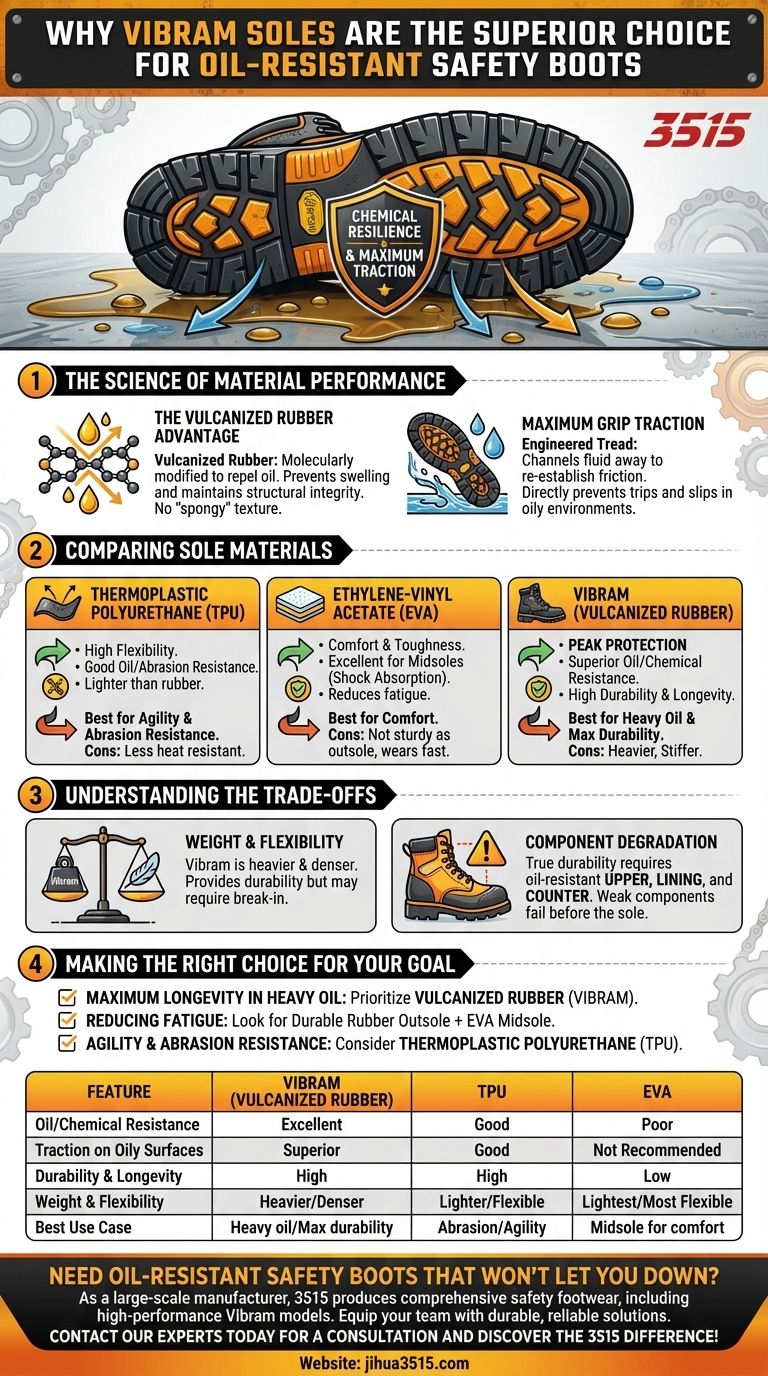

The Science of Material Performance

The Vulcanized Rubber Advantage

Vibram soles rely on vulcanized rubber, a material treated to withstand extreme conditions.

This process modifies the rubber at a molecular level, creating a barrier that repels oil rather than absorbing it.

This ensures the sole retains its shape and hardness, preventing the "spongy" texture that indicates material failure.

Maximum Grip Traction

Oil creates a lubricating film between the boot and the floor, drastically reducing friction.

Vibram outsoles are designed with specific tread patterns that channel fluids away from the contact patch, re-establishing friction with the ground.

This engineering directly addresses the need for prevention of trips and slips in slick, oily environments.

Comparing Sole Materials

To understand why Vibram (rubber) is preferred, you must compare it to other common safety boot materials found in your references.

Thermoplastic Polyurethane (TPU)

TPU is a strong competitor to rubber, offering high flexibility and resistance to abrasions and stress.

It is effective for oil resistance and is often lighter than traditional rubber.

However, for environments requiring maximum heat resistance alongside oil resistance, vulcanized rubber often maintains an edge.

Ethylene-Vinyl Acetate (EVA)

EVA is frequently cited for its comfort, toughness, and flexibility.

It is an excellent material for midsoles because it reduces fatigue for workers who stand all day.

However, as a direct outsole material, it is not very sturdy and tends to wear down significantly faster than rubber or TPU when exposed to abrasive surfaces.

Understanding the Trade-offs

While Vibram and vulcanized rubber offer peak protection, there are functional trade-offs to consider.

Weight and Flexibility

Vulcanized rubber is generally heavier and denser than materials like EVA or TPU.

This density provides durability but may result in a stiffer boot that requires a longer break-in period.

Component Degradation

A Vibram sole protects the bottom of your foot, but it is only one part of the equation.

As noted in the references, true durability requires that the counter, lining, and upper also be designed to resist oil damage.

If you select a boot with a high-quality sole but a weak upper, the leather or synthetic material may rot from oil exposure long before the sole wears out.

Making the Right Choice for Your Goal

Selecting the right footwear depends on balancing durability with the specific physical demands of your workspace.

- If your primary focus is maximum longevity in heavy oil: Prioritize vulcanized rubber (Vibram) outsoles, as they resist chemical breakdown better than softer compounds.

- If your primary focus is reducing fatigue over long shifts: Look for a boot that combines a durable rubber outsole with an EVA midsole to absorb shock without sacrificing external toughness.

- If your primary focus is agility and abrasion resistance: Consider Thermoplastic Polyurethane (TPU) soles, which offer a blend of lightweight flexibility and oil resistance.

The best safety boot is one where the chemical resistance of the sole matches the intensity of the hazards you face daily.

Summary Table:

| Feature | Vibram (Vulcanized Rubber) | TPU | EVA |

|---|---|---|---|

| Oil/Chemical Resistance | Excellent | Good | Poor |

| Traction on Oily Surfaces | Superior | Good | Not Recommended |

| Durability & Longevity | High | High | Low |

| Weight & Flexibility | Heavier, Denser | Lighter, Flexible | Lightest, Most Flexible |

| Best Use Case | Heavy oil, maximum durability | Abrasion resistance, agility | Midsole for comfort |

Need oil-resistant safety boots that won't let you down?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, including models featuring high-performance Vibram soles designed for maximum chemical resistance and worker safety.

Let us help you equip your team with durable, reliable footwear tailored to your specific industrial hazards. Contact our experts today for a consultation and discover the 3515 difference!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What is puncture resistance in safety footwear? Your Guide to Essential Foot Protection

- Why are slip-resistant soles important in oilfield safety shoes? Essential Traction to Prevent Falls

- What are the advantages of using leather for safety shoes? Superior Durability, Breathability & Comfort

- What final touches are added to safety shoes before packaging? Ensure Quality and Compliance

- What is the necessity of using a digital surface roughness tester for floor characterization? Precision Safety Data

- Why are professional safety shoes required during heavy-duty girder erection? Essential Protection for Infrastructure

- How does high-precision CT equipment evaluate footwear? Engineering Safer Boots Through Bone Density Analysis

- What additional specifications should be considered when choosing safety toe boots? Match Your Boot to Your Job's Hazards