The fundamental choice between leather and rubber firefighting boots comes down to a trade-off between support and environmental resistance. Leather boots generally offer superior ankle support, a lighter weight to reduce fatigue, and better slip resistance. In contrast, rubber boots provide greater durability, flexibility, and are almost always more waterproof and easier to decontaminate.

The decision is not about which material is universally superior, but about which set of characteristics best aligns with your specific firefighting environment, physical demands, and budget. Both materials are capable of meeting the critical NFPA 1971 safety standards.

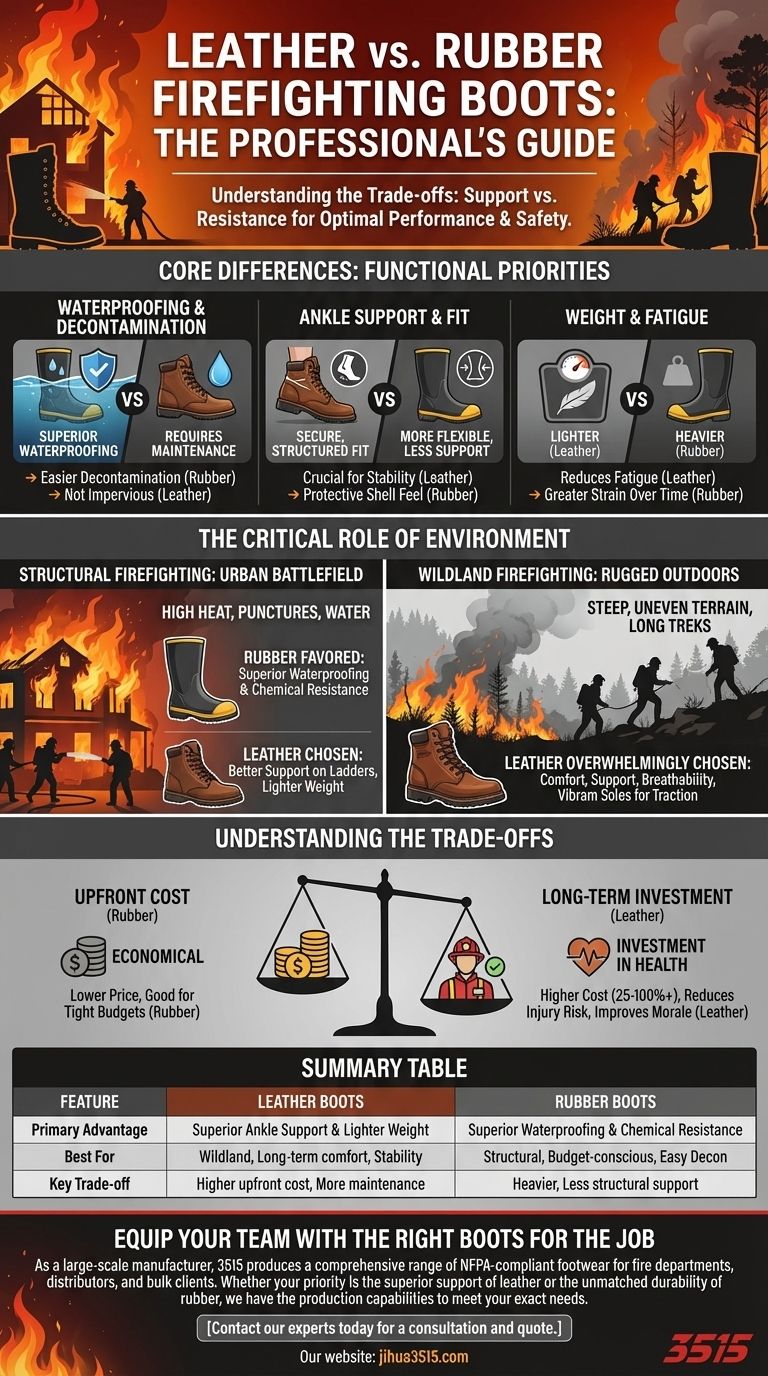

Core Differences: Support vs. Resistance

The two materials present a clear choice between different functional priorities. Understanding these distinctions is the first step in selecting the right tool for the job.

### Waterproofing and Decontamination

Rubber is inherently more waterproof than leather. Its non-porous surface makes it easier to clean and decontaminate after exposure to hazardous fluids and chemicals, a significant advantage in structural firefighting.

Leather can be treated for water resistance, but it is not impervious and requires more maintenance to retain this quality.

### Ankle Support and Fit

Leather boots typically provide a more structured and secure fit around the foot and ankle. This enhanced support is crucial for stability on uneven ground and can help prevent sprains and injuries.

While functional, rubber boots are generally more flexible and offer less structural support, feeling more like a protective shell.

### Weight and Fatigue

Leather boots are often lighter than their rubber counterparts. Over a long shift or a demanding incident, this reduction in weight can significantly decrease firefighter fatigue.

The heavier nature of rubber boots can contribute to greater physical strain over extended periods of use.

The Critical Role of Your Environment

The most important factor in your decision is the primary environment where you operate. Structural and wildland firefighting place vastly different demands on footwear.

### Structural Firefighting: The Urban Battlefield

This is where the debate between leather and rubber is most prominent. Structural boots are built for high heat, puncture hazards from debris, and constant exposure to water.

Rubber is often favored here for its superior waterproofing and chemical resistance. Leather is chosen for its better support on ladders and lighter weight, which can be a key factor in firefighter comfort and endurance.

### Wildland Firefighting: The Rugged Outdoors

In wildland environments, the choice is overwhelmingly leather. Firefighters face steep, uneven terrain for extended periods, making comfort and support paramount.

Leather's breathability and ability to mold to the foot over time provide the necessary comfort for long treks. The material's ruggedness and the sturdy Vibram soles typically paired with it offer the traction needed on unpredictable ground.

Understanding the Trade-offs

Choosing the right boot requires an honest assessment of cost versus long-term performance and comfort.

### The Upfront Cost

Rubber boots are the more economical option. They are consistently less expensive, with leather boots costing anywhere from 25% to 100% more.

This makes rubber an attractive choice for departments working with tight budgets who need to equip numerous firefighters with NFPA-compliant gear.

### The Long-Term Investment

While more expensive, a well-fitting leather boot can be seen as an investment in firefighter health. The superior support and lighter weight can reduce fatigue and the risk of musculoskeletal injuries over a career.

The comfort provided by leather can also improve morale and performance during long, grueling incidents.

Making the Right Choice for Your Role

Your decision should be guided by your primary operational needs, budget, and priorities for firefighter well-being.

- If your primary focus is budget and superior water/chemical resistance: Rubber boots provide certified protection at a lower price point and are easier to decontaminate.

- If your primary focus is firefighter comfort, ankle support, and reduced fatigue: Leather boots are a worthwhile investment for their lighter weight and more ergonomic fit.

- If your primary focus is wildland firefighting: Rugged leather boots are the established standard, offering the durability, support, and traction required for difficult terrain.

Ultimately, the best boot is the one that protects you effectively while allowing you to perform your job with confidence and minimal physical strain.

Summary Table:

| Feature | Leather Boots | Rubber Boots |

|---|---|---|

| Primary Advantage | Superior Ankle Support & Lighter Weight | Superior Waterproofing & Chemical Resistance |

| Best For | Wildland, Long-term comfort, Stability on ladders | Structural, Budget-conscious departments, Easy decontamination |

| Key Trade-off | Higher upfront cost, Requires more maintenance | Heavier, Less structural support |

Equip Your Team with the Right Boots for the Job

As a large-scale manufacturer, 3515 produces a comprehensive range of NFPA-compliant footwear for fire departments, distributors, and bulk clients. Whether your priority is the superior support of leather or the unmatched durability of rubber, we have the production capabilities to meet your exact needs.

Let us help you make the best investment in your team's safety and performance. Contact our experts today for a consultation and quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- What is the difference in traction between tactical boots and regular shoes? Find the Right Grip for Your Terrain

- What makes a shoe tactical? Purpose-Built for Demanding Environments

- What is the application value of polyurethane elastomers? Enhance Safety Shoes and Tactical Boots with High-Tech Soles

- What are the main benefits of tactical boots? Superior Protection, Comfort & Durability

- How do tactical boots differ from regular footwear? A Guide to Purpose-Built Performance

- What functional features do tactical boots and sneakers have in common? Discover the Core Performance DNA

- What should be considered for stability and support in tactical boots? A Guide to Ankle Protection & Fatigue Reduction

- What electric shock resistance standards do tactical work boots meet? A Guide to ASTM F2413 & CSA-Z195