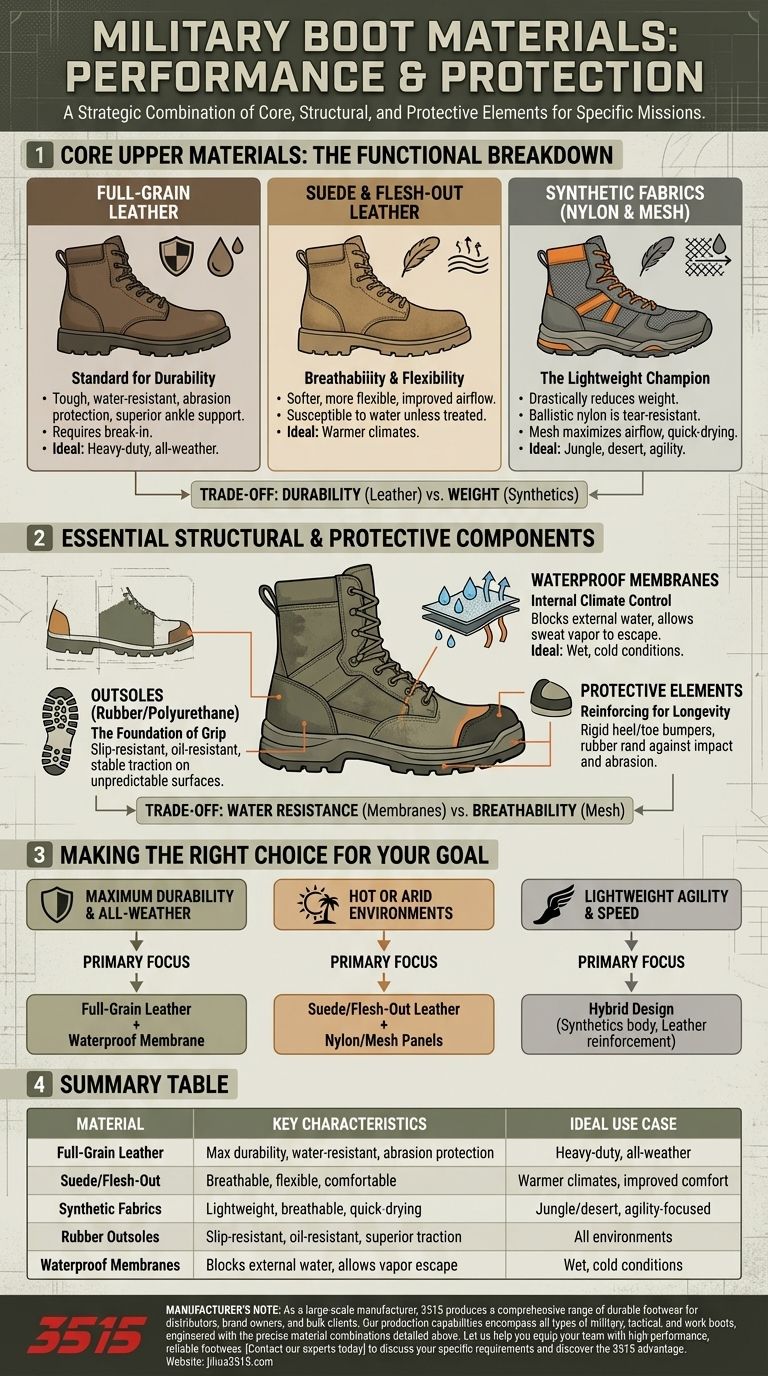

At their core, military boots are constructed from a strategic combination of three primary material categories: full-grain leather, suede (or flesh-out leather), and advanced synthetic fabrics like ballistic nylon. Each material is chosen for a specific performance characteristic, balancing durability against weight and environmental protection.

The selection of a military boot's material is never arbitrary. It is a calculated trade-off between the rugged durability of leather and the lightweight, breathable performance of modern synthetic textiles, engineered to give the wearer a distinct advantage in a specific environment.

The Core Upper Materials: A Functional Breakdown

The "upper" is the part of the boot that covers the foot. Its material composition dictates the boot's primary performance attributes, from water resistance to breathability.

Full-Grain Leather: The Standard for Durability

Full-grain leather is the toughest and most durable leather available. It is naturally water-resistant and provides excellent protection against abrasions and rough terrain.

This material offers superior ankle support but often requires a "break-in" period to achieve maximum comfort and flexibility. It remains the benchmark for heavy-duty, all-purpose combat boots.

Suede & Flesh-Out Leather: Breathability and Flexibility

Suede and flesh-out leather are essentially the same concept: leather where the rough, fibrous side faces out. This construction is softer and more flexible than full-grain leather from the start.

Its primary advantage is improved breathability, making it more comfortable in warmer climates. However, it is more susceptible to water absorption and stains unless specifically treated.

Synthetic Fabrics (Nylon & Mesh): The Lightweight Champion

Modern military boots increasingly rely on synthetics like ballistic nylon and integrated mesh panels. These materials drastically reduce the boot's overall weight.

Ballistic nylon is exceptionally resistant to tearing and abrasion while remaining highly breathable. Mesh panels are often used in "jungle" or desert boots to maximize airflow and allow water to drain quickly, promoting faster drying.

Essential Structural and Protective Components

Beyond the main uppers, specific materials are used to reinforce the boot's structure and protect the user.

Outsoles: The Foundation of Grip

The outsole is the critical point of contact with the ground. It is almost always made from a durable rubber or polyurethane compound.

These materials are engineered to be slip-resistant, oil-resistant, and capable of providing stable traction across a wide variety of unpredictable surfaces.

Protective Elements: Reinforcing for Longevity

To increase durability in high-wear areas, boots incorporate dedicated protective elements. These include rigid heel and toe bumpers to guard against impact.

Many designs also feature a rubber rand, which is a strip of rubber that wraps around the boot where the upper meets the outsole, shielding the seam from moisture and abrasion.

Waterproof Membranes: Internal Climate Control

For operations in wet conditions, many boots feature an internal waterproof membrane. This is a specialized layer laminated between the outer material and the inner lining.

This technology is designed to block external water from entering the boot while still allowing sweat vapor to escape, keeping the foot dry from both outside moisture and internal perspiration.

Understanding the Trade-offs

There is no single "best" material for a military boot. The optimal choice is always a compromise based on the intended mission and environment.

Durability vs. Weight

A boot made entirely of full-grain leather will offer maximum durability and protection but will also be significantly heavier. A boot made primarily of nylon and synthetics will be far lighter and more agile but may offer less long-term resilience under extreme abuse.

Water Resistance vs. Breathability

A fully waterproof boot with an internal membrane is ideal for cold, wet climates. However, that same membrane can trap heat and reduce breathability in a hot, arid desert, where a boot with mesh panels would perform far better by promoting rapid cooling and drying.

Making the Right Choice for Your Goal

Your primary objective dictates the ideal material composition for your footwear.

- If your primary focus is maximum durability and all-weather use: Choose a boot constructed primarily from full-grain leather, often with a waterproof membrane.

- If your primary focus is performance in hot or arid environments: Prioritize boots made with a combination of suede or flesh-out leather and large panels of nylon or mesh for breathability.

- If your primary focus is lightweight agility and speed: Look for a hybrid design that uses synthetics for the main body and reinforces critical areas with leather.

Ultimately, understanding these materials empowers you to select footwear as a piece of precision-engineered equipment, perfectly matched to the task at hand.

Summary Table:

| Material | Key Characteristics | Ideal Use Case |

|---|---|---|

| Full-Grain Leather | Maximum durability, water-resistant, abrasion protection | Heavy-duty, all-weather environments |

| Suede / Flesh-Out Leather | Breathable, flexible, comfortable | Warmer climates, improved comfort |

| Synthetic Fabrics (Nylon/Mesh) | Lightweight, breathable, quick-drying | Jungle/desert boots, agility-focused missions |

| Rubber Outsoles | Slip-resistant, oil-resistant, superior traction | All environments, critical for ground contact |

| Waterproof Membranes | Blocks external water, allows vapor escape | Wet, cold conditions |

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of military, tactical, and work boots, engineered with the precise material combinations detailed above to meet any operational demand. Let us help you equip your team with high-performance, reliable footwear. Contact our experts today to discuss your specific requirements and discover the 3515 advantage.

Visual Guide

Related Products

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Wholesale Tactical Boots High-Traction & Reflective for Bulk & Brand Orders

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

People Also Ask

- Why is safety and comfort important in military boots? The Key to Soldier Endurance and Mission Success

- What activities are combat boots suitable for? A Guide to Rugged Footwear for Demanding Use

- What are some real-world experiences of hikers using military boots? Discover the pros and cons for your next trek.

- What are the key reasons military camouflage boots are essential? Unmatched Protection, Mobility & Endurance

- Can jungle boots be used in temperate climates? Maximize Comfort in Warm, Wet Conditions

- What are the key properties influenced by the materials and production methods of military boots?

- How does hiking terrain affect the suitability of military boots? Match Your Boots to the Trail for Optimal Performance

- What issues were associated with outdated drain holes in jungle boots? Flawed Design, Clogging & Foot Health Risks