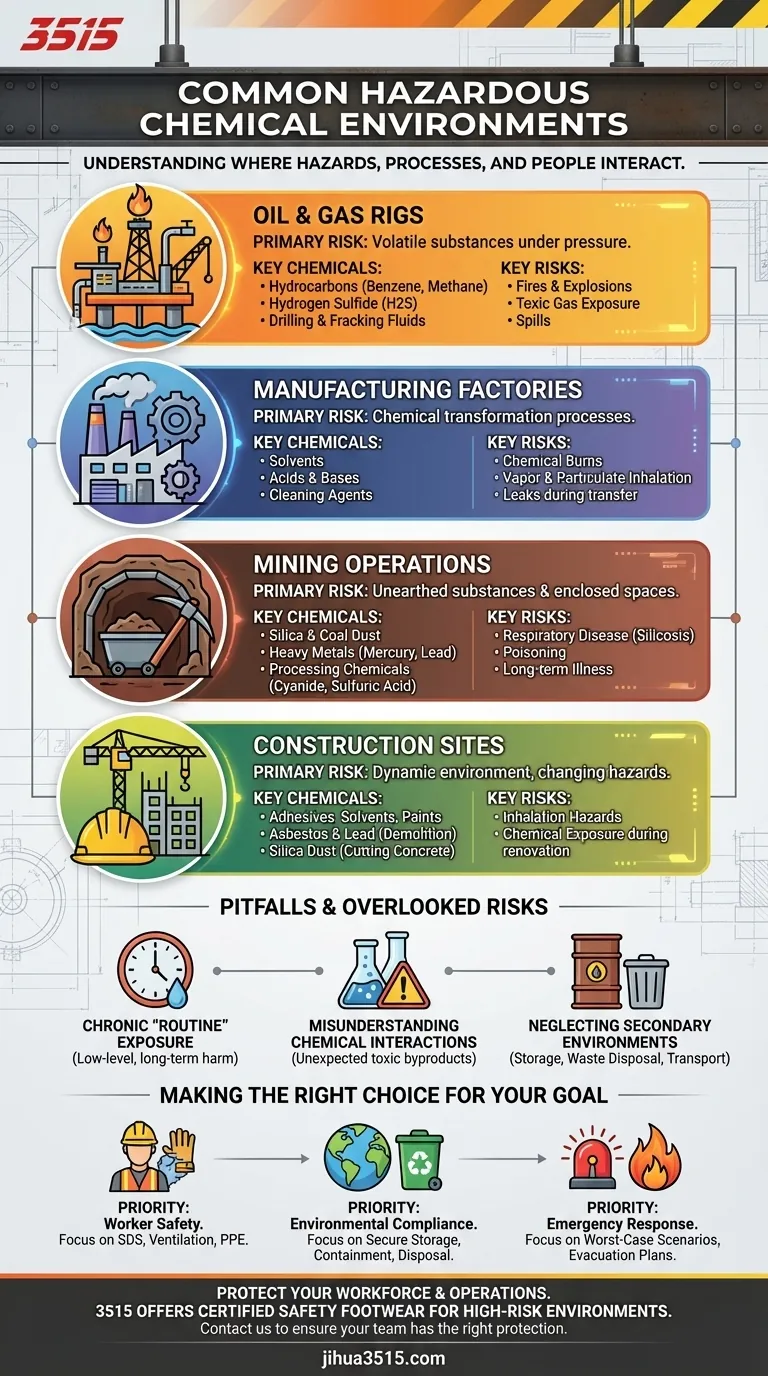

At a glance, hazardous chemicals are most commonly present in industrial environments where materials are extracted, processed, or manufactured. The primary locations include oil and gas rigs, manufacturing factories, mining operations, and construction sites, each with a distinct profile of chemical risk tied directly to its core activities.

Understanding the environment is about more than just naming a location; it's about recognizing how specific industrial processes create unique chemical hazards. The key to safety is understanding the interaction between the chemical, the process, and the physical space.

Deconstructing the Primary Hazard Zones

While the term "hazardous environment" is broad, the risks are highly specific to the industry. The nature of the operation dictates the types of chemicals present, their state (gas, liquid, solid), and the potential pathways for exposure.

Oil and Gas Rigs: A Volatile Mix

Oil and gas operations inherently involve managing volatile and toxic substances under high pressure. The primary risk comes from the raw materials being extracted.

Workers are exposed to hydrocarbons like benzene and methane, as well as hydrogen sulfide (H2S), a highly toxic gas. Additionally, the drilling and hydraulic fracturing fluids themselves contain a complex mixture of proprietary chemicals.

Manufacturing Factories: The Chemical Recipe

Factories are defined by the transformation of raw materials into finished goods, a process that often requires a wide array of chemical agents.

Common hazards include solvents, cleaning agents, acids, and bases used in production. Risks arise from potential leaks, spills during transfer, and airborne exposure to vapors or particulates generated during manufacturing processes.

Mining Operations: Unearthing Hidden Dangers

Mining brings workers into direct contact with substances that were previously trapped underground, often in enclosed spaces with limited ventilation.

The most pervasive risks include airborne dusts, such as silica and coal dust, which cause long-term respiratory disease. Miners can also be exposed to heavy metals like mercury and lead, or processing chemicals such as cyanide and sulfuric acid used to separate minerals from ore.

Construction Sites: A Constantly Changing Landscape

Construction sites are dynamic environments where the chemical hazards change daily based on the project's phase. The risk is not static.

Workers handle adhesives, solvents, paints, and sealants. Demolition or renovation of older structures can release hazardous materials like asbestos and lead. Cutting concrete or stone generates fine silica dust, a significant inhalation hazard.

Common Pitfalls and Overlooked Risks

A simplistic view of hazardous environments can lead to critical safety oversights. The most severe issues often arise from underestimating chronic risks or focusing only on the most obvious chemical sources.

The Danger of "Routine" Exposure

Many safety protocols focus on preventing large-scale, acute incidents like spills or explosions. However, the more insidious danger is often the chronic, low-level exposure to vapors or dusts that occurs daily.

This long-term exposure is a leading cause of occupational illness but is frequently overlooked because its effects are not immediate.

Misunderstanding Chemical Interactions

A common mistake is evaluating chemicals in isolation. The risk profile can change dramatically when substances are mixed, either intentionally or accidentally.

Combining certain chemicals can create unexpected and highly toxic byproducts, a danger that is not always apparent from individual safety data sheets.

Neglecting Secondary Environments

The primary production line is not the only place where hazards exist. Storage areas, waste disposal sites, and transportation logistics are also high-risk zones.

Improperly stored chemicals can degrade, leak, or react over time. These secondary environments demand the same level of rigorous safety management as the main operational area.

Making the Right Choice for Your Goal

Your approach to managing chemical hazards should be tailored to your specific responsibilities and objectives within the environment.

- If your primary focus is worker safety: Prioritize understanding the specific Safety Data Sheets (SDS) for all materials and implementing robust ventilation and Personal Protective Equipment (PPE) protocols.

- If your primary focus is environmental compliance: Concentrate on secure storage, spill containment procedures, and proper disposal methods for all chemical byproducts and waste.

- If your primary focus is emergency response planning: Identify the worst-case scenarios for each key chemical, such as a large-scale leak or fire, and develop clear, drilled evacuation and containment plans.

A clear understanding of your specific operational environment is the first and most critical step toward mitigating chemical risk.

Summary Table:

| Environment | Common Hazardous Chemicals | Primary Risks |

|---|---|---|

| Oil & Gas Rigs | Hydrocarbons (benzene), H2S, drilling fluids | Fires, explosions, toxic gas exposure |

| Manufacturing Factories | Solvents, acids, bases, cleaning agents | Chemical burns, vapor inhalation, spills |

| Mining Operations | Silica/coal dust, heavy metals, cyanide | Respiratory disease, poisoning, long-term illness |

| Construction Sites | Adhesives, paints, asbestos, silica dust | Inhalation hazards, chemical exposure during demolition |

Protect your workforce and operations from chemical hazards. As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear designed for distributors, brand owners, and bulk clients working in these high-risk environments. Our production capabilities include chemical-resistant boots and shoes that meet the stringent safety standards required in oil & gas, manufacturing, mining, and construction. Contact us today to discuss your specific needs and ensure your team has the right protective footwear.

Visual Guide

Related Products

- Wholesale Customizable Suede Safety Boots - Puncture-Proof with Velcro Closure

- Wholesale Durable Camo Canvas Shoes with High-Traction Rubber Soles

- Customizable Slip-On Safety Shoes Direct from the Factory for Wholesale

- Wholesale Mesh Steel Toe Safety Shoes with Dial Closure Factory Production

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

People Also Ask

- What are the four key aspects to consider when choosing high-quality safety footwear? Ensure True Anatomical Fit & Protection

- What regular maintenance checks should be performed on safety boots? A Daily Safety Checklist

- What organization sets national standards for workplace safety in the U.S.? OSHA's Role Explained

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- How does ASTM differ from ANSI? Navigating the U.S. Standards System for Compliance