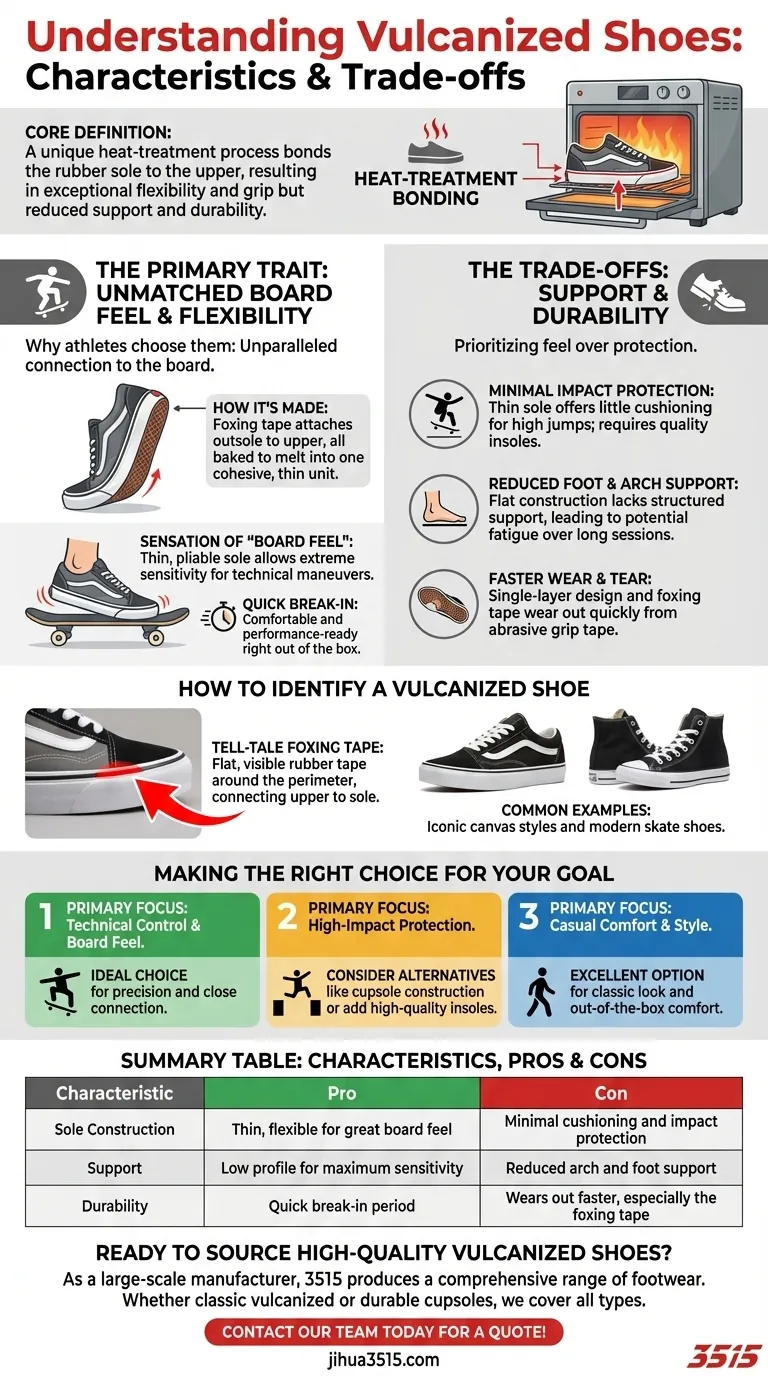

At their core, vulcanized shoes are defined by a unique heat-treatment process that bonds the shoe's rubber sole to its upper. This results in a shoe that is exceptionally flexible and grippy, offering a distinct "board feel," but this comes at the cost of reduced foot support and overall durability.

The essential trade-off of a vulcanized shoe is simple: it sacrifices impact protection and long-term durability to provide the absolute best in flexibility, grip, and board sensitivity.

The Defining Trait: Unmatched Board Feel and Flexibility

The primary reason athletes, especially skateboarders, choose vulcanized shoes is for the unparalleled connection they provide between the foot and the board. This is a direct result of their unique construction.

How Vulcanization Creates Flexibility

The vulcanization process involves taking the shoe's upper and using a strip of rubber, called foxing tape, to attach the outsole. The entire shoe is then baked in a special oven, which cures the rubber, effectively melting and bonding all the pieces into a single, cohesive, and highly flexible unit.

The Sensation of "Board Feel"

This construction results in a very thin and pliable sole. It allows your foot to feel the contours and concave of the board with incredible sensitivity, which is crucial for technical maneuvers like flip tricks or adjusting foot position in a bowl. It's often described as the closest you can get to the feeling of skating barefoot.

A Quick Break-in Period

Because the entire shoe is so flexible from the start, vulcanized shoes require almost no break-in time. They feel comfortable and ready for performance right out of the box.

Understanding the Trade-offs: Support and Durability

The very features that give vulcanized shoes their signature feel also create their most significant drawbacks. The design prioritizes feel over protection.

Minimal Impact Protection

The thin sole offers very little cushioning against high-impact landings. Activities that involve jumping down stairs or large gaps can be harsh on the feet, as there isn't much material to absorb the force. While quality insoles can help mitigate this, the shoe's fundamental construction lacks protective mass.

Reduced Foot and Arch Support

The simple, flat construction does not typically include the structured arch support found in more robust shoe designs. Over long sessions, this can lead to foot fatigue for some users.

Faster Wear and Tear

The single-layer construction, while flexible, tends to wear out more quickly than thicker, multi-part soles. The foxing tape that holds the shoe together is often a primary point of failure, especially when subjected to the abrasive friction of skate grip tape.

How to Identify a Vulcanized Shoe

You can typically spot a vulcanized shoe with a quick visual inspection.

The Tell-Tale Foxing Tape

The most obvious characteristic is the flat, level strip of rubber tape that runs around the entire perimeter of the shoe, connecting the upper to the sole. This visible seam is a hallmark of the vulcanization process.

Common Examples in Footwear

Classic canvas shoes like Vans Authentics or Converse Chuck Taylors are iconic examples of vulcanized construction. Many modern skate shoes and even simple rain boots also use this method.

Making the Right Choice for Your Goal

Selecting a vulcanized shoe depends entirely on what you prioritize in your footwear.

- If your primary focus is technical control and board feel: A vulcanized shoe is the ideal choice for activities requiring precision and a close connection to your board.

- If your primary focus is high-impact protection: You should consider alternatives with a cupsole construction or be prepared to add high-quality aftermarket insoles.

- If your primary focus is casual comfort and style: The classic look and out-of-the-box flexibility make vulcanized shoes an excellent option for everyday wear.

Ultimately, choosing a vulcanized shoe is a conscious decision to prioritize sensitivity and flexibility above all else.

Summary Table:

| Characteristic | Pro | Con |

|---|---|---|

| Sole Construction | Thin, flexible for great board feel | Minimal cushioning and impact protection |

| Support | Low profile for maximum sensitivity | Reduced arch and foot support |

| Durability | Quick break-in period | Wears out faster, especially the foxing tape |

Ready to source high-quality vulcanized shoes?

As a large-scale manufacturer, 3515 produces a comprehensive range of vulcanized and other footwear for distributors, brand owners, and bulk clients. Whether you need classic vulcanized styles for superior board feel or durable cupsole alternatives, our production capabilities cover all types of shoes and boots.

Contact our team today to discuss your specific needs and get a quote!

Visual Guide

Related Products

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Durable Canvas Work Shoes with Rubber Lug Sole | Wholesale Manufacturer

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable Camo Canvas Shoes with High-Traction Rubber Soles

- Wholesale Durable Camouflage Canvas Shoes with High-Traction Cleated Rubber Sole

People Also Ask

- What role does shock-absorbing cushioning play in preventing muscle fatigue? Boost Performance & Endurance

- What is the significance of a constant-temperature environment during footwear testing? Ensure Data Accuracy

- What is the relationship between footwear design and the effectiveness of biomechanical alignment? Maximize Stability

- What is the importance of using high-precision anthropometric measurements in footwear development? Data Standardization

- How are the design advantages of training shoes quantified in thermal models? Metrics for Human Protection