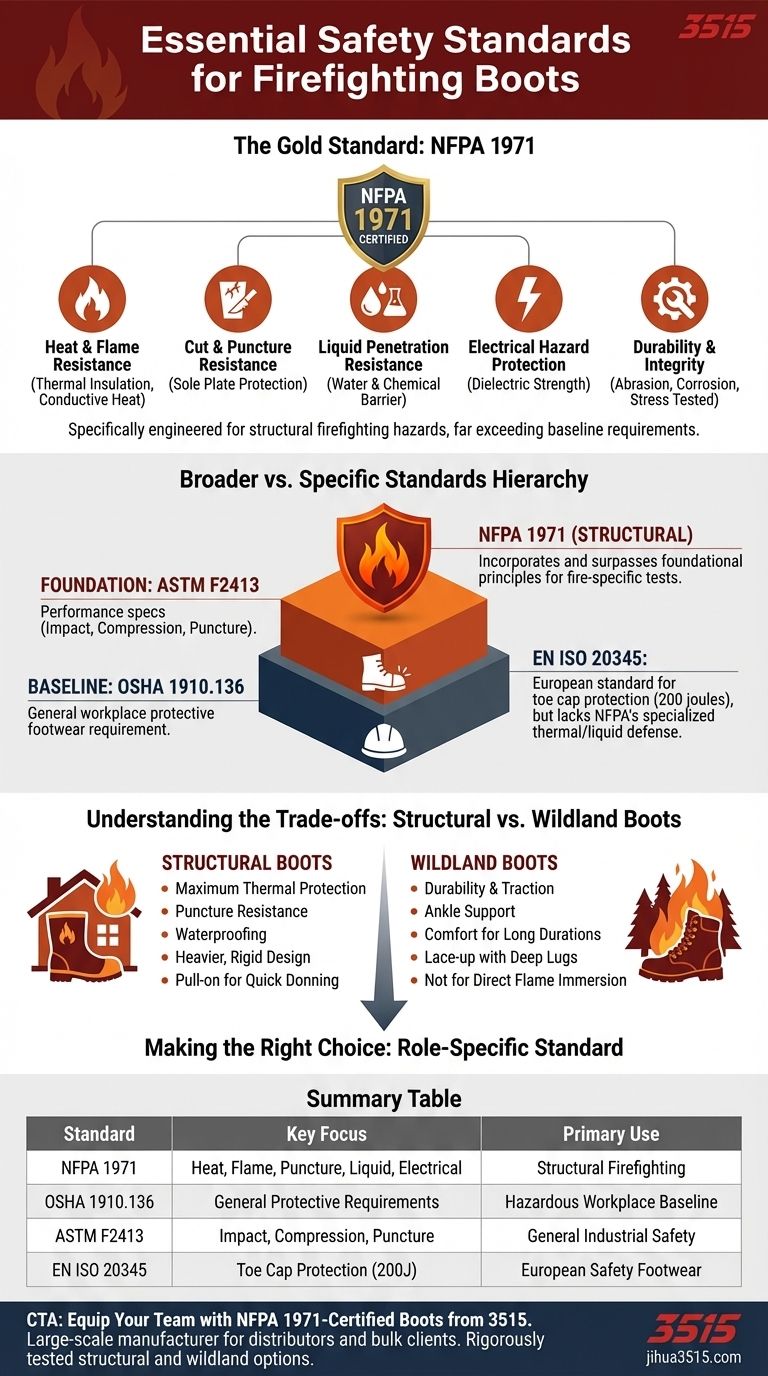

For firefighting operations in the United States, the most critical safety standard for boots is NFPA 1971, which is the "Standard on Protective Ensembles for Structural Fire Fighting and Proximity Fire Fighting." While general safety regulations like OSHA 1910.136 and ASTM F2413 apply to protective footwear, boots certified to NFPA 1971 are specifically engineered for firefighting hazards and far exceed these baseline requirements.

Relying on a specific, job-related standard like NFPA 1971 is the only reliable method to ensure firefighting boots provide comprehensive protection. This certification guarantees the footwear has passed a rigorous battery of tests for the extreme thermal, physical, and chemical hazards encountered on the fire ground.

Decoding the Core Standard: NFPA 1971

NFPA 1971 is the definitive standard for structural firefighting personal protective equipment (PPE) in North America. When a boot is certified to this standard, it has been independently verified to meet stringent performance criteria.

Heat and Flame Resistance

The most obvious threat in a fire is extreme heat. NFPA 1971 mandates tests for conductive heat resistance and thermal insulation, ensuring the boot protects the wearer's foot from burns when walking on hot surfaces or being exposed to ambient heat.

Cut and Puncture Resistance

The fire ground is often littered with sharp debris like glass, nails, and twisted metal. The standard requires a puncture-resistant sole plate to protect the bottom of the foot from penetration.

Liquid Penetration Resistance

Boots must keep feet dry not only from water but also from potentially hazardous fluids. This standard ensures the boot's materials and construction resist penetration by water and other common chemicals for a specified period.

Electrical Hazard Protection

In a structural environment, live electrical wires are a significant risk. NFPA 1971 includes requirements for dielectric strength, ensuring the boots provide a degree of insulation against electrical shock at a specific voltage.

Durability and Physical Integrity

The standard includes tests for abrasion, corrosion, and overall durability. This ensures the boot will not fail under the intense physical stress of firefighting operations.

Broader Standards vs. Firefighting-Specific Standards

It's crucial to understand the hierarchy of standards. While you may see other designations, they serve as a foundation, not a replacement for NFPA 1971 in a structural firefighting context.

OSHA 1910.136: The Baseline

This regulation from the Occupational Safety and Health Administration (OSHA) is a general requirement for protective footwear in any hazardous workplace. It's the minimum legal baseline, which NFPA-compliant boots easily surpass.

ASTM F2413: The Foundation

This specification from ASTM International covers performance requirements for all types of protective footwear. It establishes the test methods for features like impact-resistant toe caps and compression resistance. NFPA 1971 incorporates and builds upon these foundational principles with its own fire-specific tests.

International Standards (EN ISO 20345)

This is a common European standard for safety footwear. It specifies that boots must have a protective toe cap that withstands 200 joules of impact. While excellent for general industrial safety, it does not include the specialized thermal and liquid protection required by NFPA 1971.

Understanding the Trade-offs: Structural vs. Wildland Boots

Not all firefighting is the same, and the boots reflect this reality. The optimal boot for a building fire is poorly suited for fighting a forest fire.

The Need for Different Designs

Structural firefighting involves intense, short-duration heat, falling debris, wet surfaces, and chemical hazards. Wildland firefighting involves long hours of hiking over steep, uneven terrain with exposure to ambient heat and embers.

Key Features of Structural Boots

Dominated by NFPA 1971 requirements, these boots prioritize maximum thermal protection, puncture resistance, and waterproofing. This results in a heavier, more rigid boot, often with a pull-on design for quick donning.

Key Features of Wildland Boots

These boots prioritize durability, ankle support, and comfort for long durations. They are typically lace-up leather boots with deep-lugged, melt-resistant soles for traction. While they offer heat resistance, they are not designed for the same direct flame and heat immersion as a structural boot.

Making the Right Choice for Your Role

Selecting the correct boot is a critical safety decision. Your specific role and environment dictate the necessary standard.

- If your primary focus is structural firefighting: Your non-negotiable requirement is a boot certified to the current edition of NFPA 1971.

- If your primary focus is wildland firefighting: Seek a durable leather boot designed for stability on rugged terrain, prioritizing comfort and support for long missions.

- If you are a safety or procurement officer: Always verify current NFPA 1971 certification for all structural PPE and ensure the chosen boot aligns with the specific hazards your team faces.

Ultimately, proper certification is the professional's assurance that their most essential tool—their footwear—is built to perform when it matters most.

Summary Table:

| Standard | Key Focus | Primary Use |

|---|---|---|

| NFPA 1971 | Heat, flame, puncture, liquid penetration, and electrical hazard resistance | Structural firefighting |

| OSHA 1910.136 | General protective footwear requirements | Baseline for hazardous workplaces |

| ASTM F2413 | Impact, compression, and puncture resistance (foundational) | General industrial safety footwear |

| EN ISO 20345 | Toe cap protection (200 joules) | European safety footwear standard |

Ensure your team is equipped with NFPA 1971-certified firefighting boots from 3515. As a large-scale manufacturer, we produce a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. Our production capabilities cover all types of structural and wildland firefighting boots, rigorously tested to meet the highest safety standards. Protect your first responders with reliable, durable footwear—contact us today to discuss your requirements!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

People Also Ask

- What is the significance of using professional tactical boots for motion tracking? Ensure Data Precision & Stability

- What adjustable features should be considered in tactical boots? Optimize Fit for Maximum Performance

- What steps can be taken to protect the soles of tactical boots? Essential Maintenance for Maximum Durability

- What are the characteristics of Men's Lightweight Tactical Boots? Speed, Agility, and All-Day Comfort

- Who are the primary users of tactical shoes? From Military to Mainstream Users

- What are the advantages of HiMAT over walking tests for tactical footwear? Unlock Elite Performance Metrics

- What are the advantages of industrial production lines for tactical boots? Achieve Consistency and Scale

- What is the necessity of structural flexibility and high-response soles? Maximize Tactical Agility and Speed