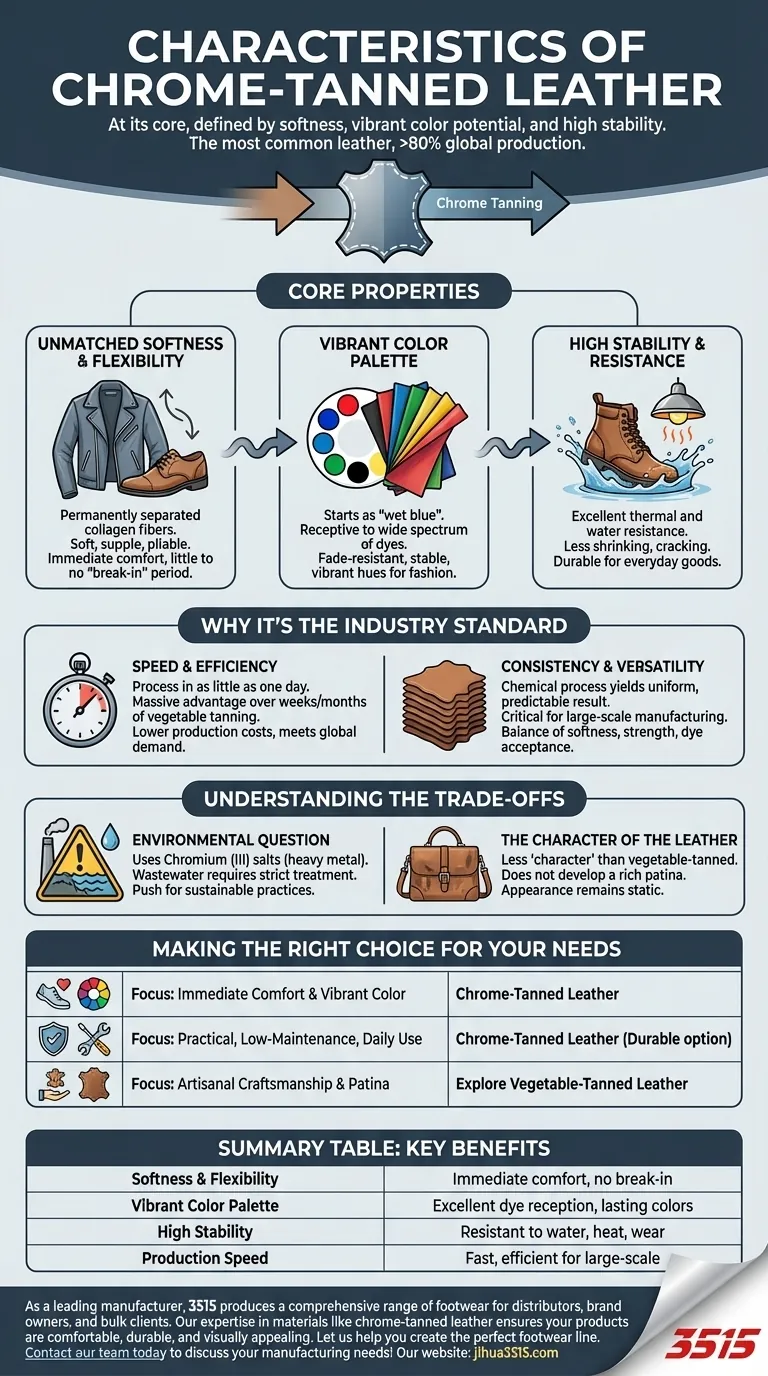

At its core, chrome-tanned leather is defined by its exceptional softness, vibrant color potential, and high stability. It is the most common type of leather in the world, accounting for over 80% of all leather production due to a fast and efficient tanning process that yields a consistent and versatile material.

The defining characteristic of chrome-tanned leather is its combination of commercial efficiency and user-focused performance, offering a soft, colorful, and durable material that is ideal for mass-produced goods.

The Core Properties of Chrome-Tanned Leather

To understand chrome-tanned leather, you must first understand the results of its unique tanning process, which uses chromium salts to preserve the animal hide. This chemical process directly imparts its most well-known characteristics.

Unmatched Softness and Flexibility

The chromium salts permanently separate the collagen fibers within the hide, preventing them from hardening. This results in a material that is notably soft, supple, and pliable right from the start.

This inherent softness means products made from it, like footwear or jackets, require little to no "break-in" period, offering immediate comfort.

A Broad and Vibrant Color Palette

The chrome tanning process leaves the leather in a pale blue-grey state often called "wet blue." This neutral base is exceptionally receptive to a wide spectrum of dyes.

As a result, chrome-tanned leather can be produced in nearly any color imaginable, from deep blacks to brilliant, vibrant hues that remain stable and fade-resistant over time. This makes it a favorite for the fashion industry.

High Stability and Resistance

Chrome-tanned leather exhibits excellent thermal and water resistance compared to other tanning methods. It is less likely to shrink, crack, or become misshapen when exposed to moderate heat or moisture.

This durability makes it a practical choice for goods intended for everyday use, such as shoes, upholstery, and handbags, where consistent performance is essential.

Why is Chrome-Tanning the Industry Standard?

Its market dominance isn't accidental. The commercial realities of modern manufacturing heavily favor the chrome-tanning method for two primary reasons: speed and consistency.

Speed and Efficiency

The entire chrome-tanning process can be completed in as little as one day. This rapid production cycle is a massive advantage over older methods, like vegetable tanning, which can take weeks or months.

This efficiency allows for lower production costs and the ability to meet the high demands of the global market, explaining why it's used in the vast majority of leather goods.

Consistency and Versatility

The chemical nature of chrome tanning produces an incredibly uniform and predictable result from one hide to the next.

This consistency is critical for large-scale manufacturing, where every product must meet the same quality standard. Its balance of softness, strength, and dye acceptance makes it a versatile choice for a huge range of applications.

Understanding the Trade-offs

No material is perfect, and the benefits of chrome-tanned leather come with important compromises that are crucial for any informed decision.

The Environmental Question

The primary drawback is its environmental impact. The process uses chromium (III) salts, which are a heavy metal.

While safe in the final product, the wastewater from tanneries can be highly toxic if not treated with strict, modern environmental controls. This has led to significant regulation and a push toward more sustainable practices.

The Character of the Leather

Chrome-tanned leather is often described as having less "character" than its vegetable-tanned counterpart. It does not develop a rich, deep patina over time.

Its appearance remains relatively static throughout its life. For those who value the way an item ages and tells a story, this can be a significant disadvantage.

Making the Right Choice for Your Needs

Selecting the right type of leather depends entirely on your priorities and the intended use of the final product.

- If your primary focus is immediate comfort and vibrant, lasting color: Chrome-tanned leather is the ideal choice due to its inherent softness and superior dye acceptance.

- If your primary focus is a practical, low-maintenance product for daily use: Its excellent resistance to water and heat makes it a reliable and durable option.

- If your primary focus is artisanal craftsmanship and a developing patina: You should explore vegetable-tanned leather, which is designed to age beautifully and uniquely over time.

Ultimately, understanding these core characteristics empowers you to select the right leather for your specific purpose and values.

Summary Table:

| Characteristic | Key Benefit |

|---|---|

| Softness & Flexibility | Immediate comfort, no break-in period |

| Vibrant Color Palette | Excellent dye reception for lasting, bright colors |

| High Stability | Resistant to water, heat, and everyday wear |

| Production Speed | Fast, efficient process ideal for large-scale manufacturing |

As a leading manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our expertise in materials like chrome-tanned leather ensures your products are comfortable, durable, and visually appealing. Let us help you create the perfect footwear line. Contact our team today to discuss your manufacturing needs!

Visual Guide

Related Products

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Premium Oil Wax Leather Safety Boots for Bulk Purchase

- Wholesale Patent Oxford Dress Shoes | Custom & Bulk Manufacturing

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Comfortable Block Heel Pumps Wholesale & Custom Factory Production

People Also Ask

- Why is conditioning important for full grain leather tactical boots? Prevent Cracking & Ensure Longevity

- Why incorporate footwear geometry into contact models? Enhance Simulation Accuracy for Tactical & Sports Gear

- What is the practical value of integrating orthopedic and traumatology research into the shoe last design for tactical boots and training shoes? Ensure Peak Performance & Injury Prevention.

- Why is the maintenance of tactical boots significant in professional image management? Enhance Your Elite Identity

- What technical specifications are required for tactical boots in limited urban infrastructure? Essential Support Guide