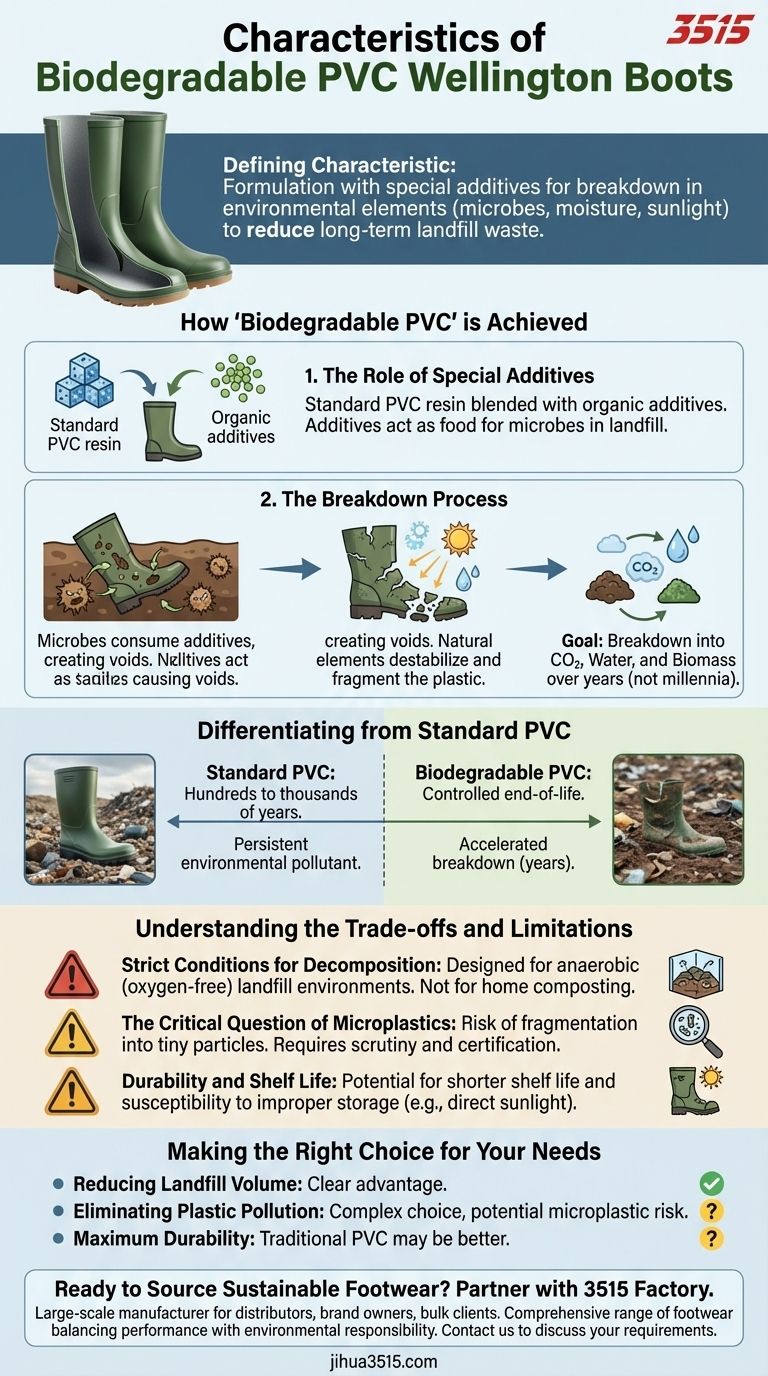

The defining characteristic of biodegradable PVC Wellington boots is their formulation with special additives that cause the plastic to break down when consistently exposed to environmental elements like microbes, moisture, and sunlight. This design aims to shorten the material's lifespan in a landfill, reducing long-term plastic waste accumulation compared to traditional PVC.

While designed to decompose and reduce permanent landfill waste, the term "biodegradable" for PVC requires careful consideration. The effectiveness and environmental safety of the breakdown process depend heavily on specific conditions and raise important questions about potential microplastic residues.

How "Biodegradable PVC" is Achieved

Polyvinyl Chloride (PVC) is not inherently biodegradable. Its famous durability is what makes it a persistent environmental pollutant. To create a biodegradable version, manufacturers must fundamentally alter its chemical stability.

The Role of Special Additives

The key to this technology is blending standard PVC resin with specific organic additives. These additives act as a food source for microbes commonly found in soil and landfill environments.

Once the boots are discarded and buried, these microbes consume the additives. This process creates microscopic voids and breaks down the molecular bonds of the surrounding PVC polymer.

The Breakdown Process

This microbial action effectively destabilizes the entire plastic structure from within. It allows natural elements like UV radiation and moisture to further fragment the material at a much faster rate than untreated PVC.

The goal is for the boot to eventually break down into simpler components like carbon dioxide, water, and biomass, rather than persisting for centuries as a whole object.

Differentiating from Standard PVC

A standard PVC Wellington boot can last for hundreds or even thousands of years in the environment without significant decomposition. Biodegradable PVC is engineered for a controlled and accelerated end-of-life, intended to happen over a period of years, not millennia.

Understanding the Trade-offs and Limitations

The claim of biodegradability is not without its complexities and potential downsides. An objective evaluation requires looking at the entire lifecycle and the specific conditions needed for decomposition.

Strict Conditions for Decomposition

These boots will not simply disappear if left in a field. The biodegradation process is designed to activate most efficiently in an anaerobic (oxygen-free) landfill environment where microbial activity is high.

In a dry or less biologically active setting, the breakdown process will be significantly slower, if it happens at all. They are not designed for home composting.

The Critical Question of Microplastics

A major concern with many "biodegradable" plastics is whether they break down completely or simply fragment into microplastics. These tiny particles can persist in the environment and enter the food chain.

It is crucial to scrutinize manufacturer claims and seek third-party certifications to understand if the end-product is benign biomass or a collection of microscopic plastic fragments.

Durability and Shelf Life

Introducing additives that promote decomposition inherently creates a trade-off with durability. While perfectly functional during their intended use, these boots may have a shorter shelf life and be more susceptible to degradation from improper storage (e.g., prolonged exposure to direct sunlight) than their conventional counterparts.

Making the Right Choice for Your Needs

Evaluating whether biodegradable PVC boots are the right choice depends entirely on your primary sustainability goal and your ability to verify the product's claims.

- If your primary focus is reducing long-term landfill volume: These boots offer a clear advantage over traditional PVC, as they are designed to break down and occupy less space over time.

- If your primary focus is eliminating all potential plastic pollution: The risk of microplastic creation makes this a more complex choice that requires deep trust in the specific manufacturer's technology.

- If your primary focus is maximum durability and longevity: A traditional PVC or natural rubber boot will likely offer a longer service life, reducing the need for frequent replacement.

Ultimately, an informed decision rests on understanding that "biodegradable" is a specific end-of-life solution, not a universal environmental panacea.

Summary Table:

| Characteristic | Description | Key Consideration |

|---|---|---|

| Core Technology | PVC resin blended with organic additives that microbes consume. | Alters the chemical stability of standard PVC to enable breakdown. |

| Breakdown Process | Microbes create voids, allowing natural elements to fragment the material. | Designed for anaerobic landfill conditions; not for home composting. |

| Primary Advantage | Reduces long-term landfill volume by breaking down over years. | A clear advantage over traditional PVC, which persists for centuries. |

| Major Limitation | Potential risk of creating microplastics if breakdown is incomplete. | Effectiveness and safety depend on specific manufacturer technology. |

| Durability Trade-off | Functional for intended use but may have a shorter shelf life. | More susceptible to degradation from improper storage than conventional boots. |

Ready to Source Sustainable Footwear? Partner with 3515 Factory.

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including developing solutions that balance performance with environmental responsibility.

Let us help you navigate the complexities of sustainable materials and deliver high-quality products that meet your customers' needs. Contact our team today to discuss your specific requirements and explore our manufacturing solutions.

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale High-Traction Camo Boots - Custom Manufacturer for Brands

People Also Ask

- What features make Wellington boots comfortable for extended outdoor use? Discover the Science of All-Day Comfort.

- What makes the grip of gardening boots essential? The Key to Safety on Unstable Ground

- What are the main benefits of PVC boots? Unmatched Waterproof & Chemical Protection

- How should half-boots be cleaned to maintain their condition? A Gentle Guide to Preserve Your Footwear

- What are gumboots primarily designed for? Unmatched Protection from Water and Mud

- Should children's wellies be bought a size bigger? Prioritize Safety and Proper Fit for Healthy Feet

- What are the key features of classic tall Wellington boots for women? | 3515 Manufacturer Guide

- What are the key factors to consider when purchasing Wellington boots? Find the Perfect Fit for Your Needs