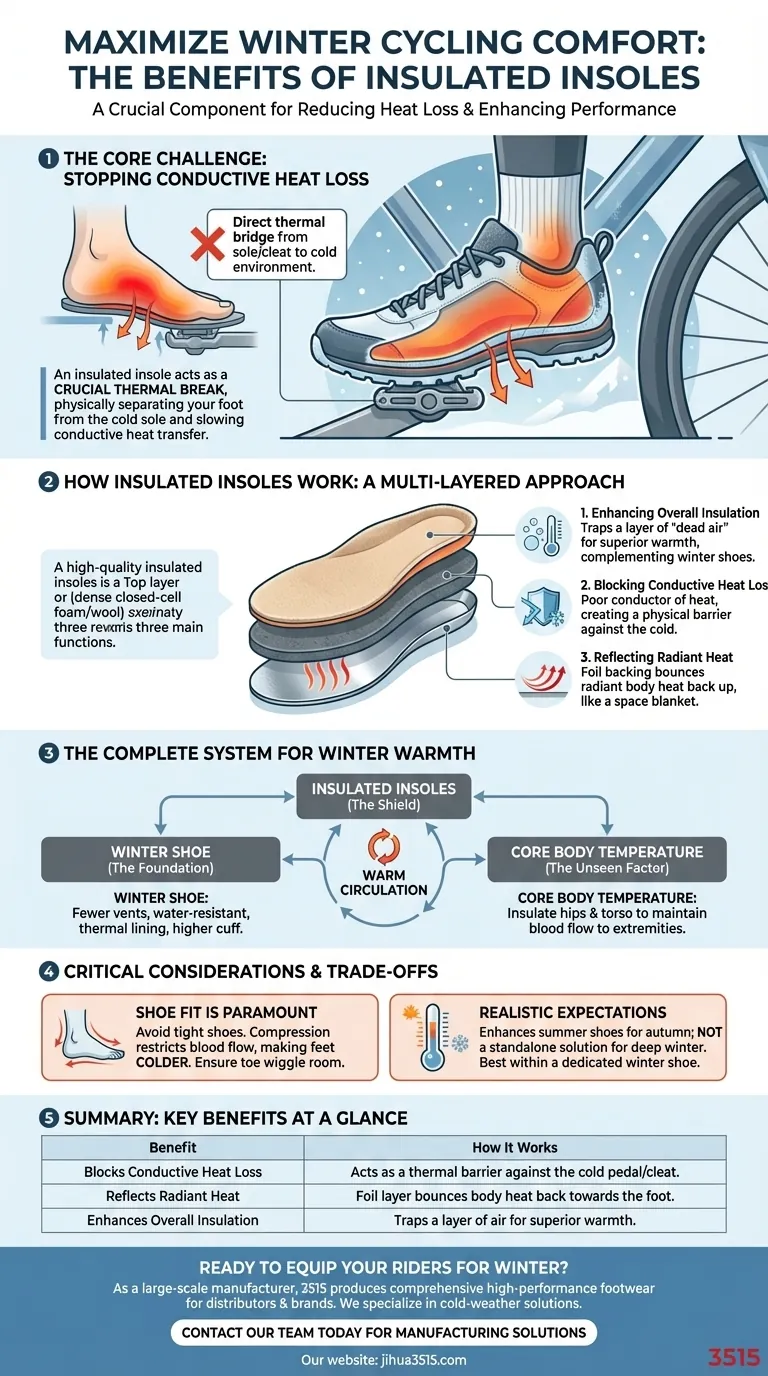

To put it simply, insulated insoles add warmth to your winter cycling shoes by creating a thermal barrier that dramatically reduces heat loss through the sole. Your feet are a primary point of contact with the cold—via the pedal and cleat—and these insoles act as a crucial shield, preventing the cold from seeping in and keeping your own body heat from escaping.

The greatest challenge in keeping feet warm is not just adding insulation, but stopping conductive heat loss. Because the sole of your shoe and metal cleat are a direct bridge to the cold, an insulated insole's primary job is to act as a thermal break, reflecting heat back to your foot and blocking the cold from the ground up.

How Insulated Insoles Work

The effectiveness of insulated insoles comes from addressing the specific ways your feet lose heat inside a cycling shoe. They are more than just a thicker piece of foam; they are engineered with thermal principles in mind.

Blocking Conductive Heat Loss

The sole of a cycling shoe is stiff and thin, designed for power transfer, not insulation. When you clip into a metal pedal, you create a direct pathway for heat to be conducted away from your foot.

An insulated insole, particularly one with materials like wool or closed-cell foam, serves as a poor conductor of heat. It physically separates your foot from the cold shoe sole, significantly slowing this transfer.

Reflecting Radiant Heat

Many high-quality winter insoles feature a foil backing on the bottom layer. This works on the same principle as a survival or "space" blanket.

This reflective layer bounces your foot's own radiant heat back up towards you instead of allowing it to be lost through the bottom of the shoe.

Enhancing Overall Insulation

A dedicated winter insole adds material and traps a layer of air within its structure. This "dead air" is an excellent insulator and complements the thermal linings found in winter-specific cycling shoes.

Insoles Are One Part of a Complete System

While effective, insulated insoles work best when they are not the only solution you rely on. True winter comfort comes from treating warmth as a system, where every component plays a role.

The Foundation: The Winter Shoe

Insulated insoles are most effective when placed inside a proper winter cycling shoe. These shoes are designed with fewer vents, water-resistant exteriors, and built-in thermal lining.

They often feature a higher ankle cuff, which prevents cold air and moisture from entering at the gap between your shoe and tights.

The Unseen Factor: Core Body Temperature

No footwear can keep your feet warm if your body is trying to conserve heat. If your core or hips get cold, your body instinctively reduces blood flow to your extremities—your hands and feet—to protect vital organs.

Insulating your hips and torso is therefore one of the most effective ways to ensure warm blood continues to circulate all the way to your toes.

Understanding the Trade-offs

Adding an insulated insole is a simple upgrade, but it's important to be aware of the potential downsides to ensure you don't inadvertently make the problem worse.

The Critical Impact on Shoe Fit

The most common mistake is adding a thick insole to an already snug shoe. A shoe that is too tight will compress your foot, restricting blood flow and making your feet colder, not warmer.

Always ensure you have enough room to wiggle your toes freely after inserting a new insole. If you don't, the insole will do more harm than good.

Setting Realistic Expectations

An insulated insole can make a summer shoe usable in chilly autumn weather, but it cannot transform it into a deep-winter boot. They are a powerful enhancement, not a magical solution for sub-freezing temperatures on their own.

How to Apply This to Your Goal

Your strategy for using insulated insoles should depend on the conditions you plan to ride in.

- If your primary focus is extending your 3-season shoes into cooler weather: A quality insulated insole is one of the most cost-effective upgrades you can make.

- If your primary focus is riding comfortably in freezing temperatures: Treat insulated insoles as a mandatory component within a dedicated winter cycling shoe.

- If your feet are still cold despite having the best footwear: Re-evaluate your overall layering, ensuring your core, hips, and legs are sufficiently insulated to maintain warm circulation.

Ultimately, managing heat loss at the sole is a non-negotiable part of comfortable winter cycling.

Summary Table:

| Benefit | How It Works |

|---|---|

| Blocks Conductive Heat Loss | Acts as a thermal barrier between your foot and the cold pedal/cleat. |

| Reflects Radiant Heat | A foil layer bounces your body heat back towards your foot. |

| Enhances Overall Insulation | Traps a layer of air for superior warmth within the shoe system. |

Ready to equip your riders for winter?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of cycling shoes and boots, including designs optimized for cold-weather performance.

We can help you develop or source the perfect winter cycling footwear solutions to keep your customers comfortable and riding all season long.

Contact our team today to discuss your specific needs and explore our manufacturing solutions.

Visual Guide

Related Products

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Wholesale Tactical Boots High-Traction & Reflective for Bulk & Brand Orders

- Premium Grain Leather Safety Boots for Bulk Supply

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

People Also Ask

- What physical protections are provided by the S1 standard and integrated steel toecaps in industrial safety boots? Ensure Ultimate Foot Safety & Hazard Protection

- Why is Production Capacity (Mcap) a core parameter in safety shoe contracts? Optimize Supply and Mitigate Risk

- What are the primary safety functions of safety boots with steel-toe designs? Essential Protection for Industry

- Why is manufacturer diversity and inclusion important in work boot design? For Superior Fit, Safety & Comfort

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management