In short, the sole of a police boot is an engineered system designed for three primary purposes: to reduce the physical toll of long shifts, to provide stable footing on unpredictable surfaces, and to protect the officer from environmental hazards. It accomplishes this through advanced materials that provide shock absorption, support, slip resistance, and chemical durability.

The core function of a police boot's sole is not just about comfort, but about mitigating long-term physical strain and immediate on-the-job risks. It acts as the critical interface between the officer and their environment, directly impacting their endurance, safety, and career longevity.

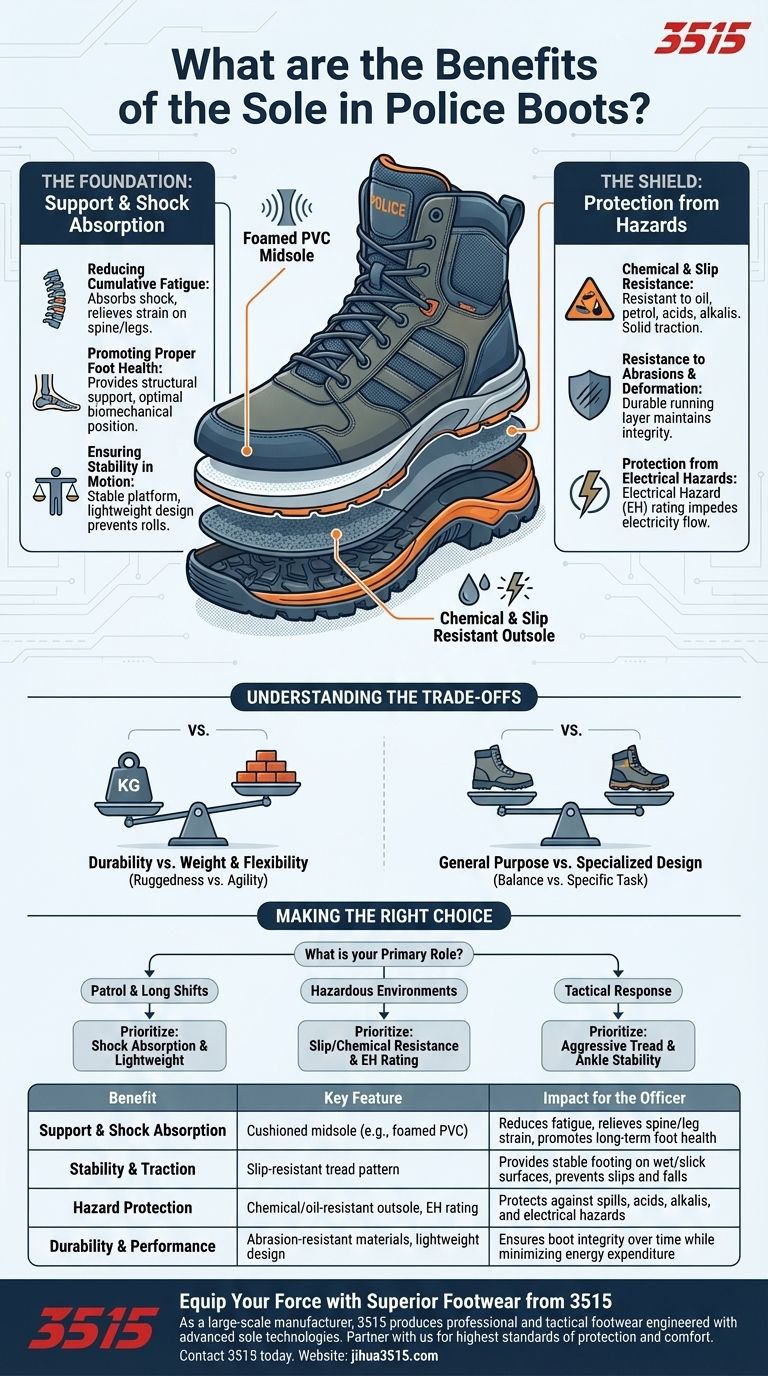

The Foundation: Support and Shock Absorption

The most fundamental benefit of a well-designed police boot sole is its ability to manage the immense physical stress placed on an officer's body. A typical shift involves hours of standing, walking, and sudden bursts of activity.

Reducing Cumulative Fatigue

The sole is engineered to absorb the shock of each step. An intermediate layer, often made of a material like foamed polyvinyl chloride, dampens the impact that would otherwise travel up through the legs, knees, and back.

This shock absorption is critical for relieving strain on the spine and leg muscles, allowing an officer to remain effective and more comfortable even after many hours on their feet.

Promoting Proper Foot Health

Beyond simple cushioning, the sole provides structural support for the entire foot. It is designed to hold the foot in an optimal biomechanical position during movement.

This support is key to preventing common foot ailments and ensuring long-term health, which is essential in a physically demanding career.

Ensuring Stability in Motion

The overall design provides a stable platform for movement. Whether walking a beat, jogging, or navigating uneven ground, the sole is built to prevent rolls and provide a confident footing.

Modern boots achieve this stability while remaining remarkably lightweight, often under 25 ounces, thanks to synthetic materials and slimmer profiles that reduce the energy an officer must expend.

The Shield: Protection from Hazards

An officer's work environment is unpredictable and often hazardous. The sole serves as a primary layer of protection against a variety of threats found on patrol or at an incident scene.

Chemical and Slip Resistance

Many police boot soles are constructed with a two-layer design where the running layer is highly durable. This outsole is specifically formulated to be resistant to oil, petrol, acids, and alkalis.

This feature provides critical protection when navigating accident scenes, industrial areas, or spills. Paired with a slip-resistant tread, it ensures solid traction on wet or slick surfaces.

Resistance to Abrasions and Deformation

The outer layer of the sole, or the "running layer," is made from materials chosen for their ability to resist abrasion and deformation. This ensures the boot maintains its structural integrity and protective qualities over time, even with heavy use on rough surfaces like asphalt and concrete.

Protection from Electrical Hazards

Some specialized police boots come with an Electrical Hazard (EH) rating. The soles of these boots are designed with materials that impede the flow of electricity, providing a secondary source of protection in environments with high-voltage risks.

Understanding the Trade-offs

No single boot sole is perfect for every situation. Understanding the inherent design compromises is key to selecting the right tool for the job.

General Purpose vs. Specialized Design

A police boot is a general-purpose tool. Its sole is designed to perform well across many activities: walking, standing, running short distances, and providing protection.

This is different from a specialized boot, like a riding boot, which has a smooth sole specifically to prevent it from catching in a stirrup. That design is excellent for its specific task but would offer poor traction for a foot patrol. A police sole must balance competing needs.

Durability vs. Weight and Flexibility

There is often a trade-off between a sole's ruggedness and its weight. A thicker, more chemical-resistant sole might be heavier, potentially increasing fatigue over a 12-hour shift.

Similarly, a more rigid sole may offer superior support and protection but sacrifice the flexibility needed for sprinting or climbing. Manufacturers are constantly innovating with new materials to minimize these compromises.

Making the Right Choice for Your Goal

The ideal boot sole depends entirely on your primary role and the environment you most frequently operate in.

- If your primary focus is patrol and long shifts on foot: Prioritize a sole with superior shock absorption and a lightweight design to minimize cumulative fatigue.

- If your primary focus is working in hazardous environments: Emphasize a sole with certified slip resistance, chemical resistance, and an Electrical Hazard (EH) rating if applicable.

- If your primary focus is tactical response or rural patrol: Look for a sole with a more aggressive tread for superior traction on varied terrain, combined with features that enhance ankle stability.

Ultimately, the right sole is a critical piece of equipment that directly supports your safety, endurance, and long-term health on the job.

Summary Table:

| Benefit | Key Feature | Impact for the Officer |

|---|---|---|

| Support & Shock Absorption | Cushioned midsole (e.g., foamed PVC) | Reduces fatigue, relieves spine/leg strain, promotes long-term foot health |

| Stability & Traction | Slip-resistant tread pattern | Provides stable footing on wet/slick surfaces, prevents slips and falls |

| Hazard Protection | Chemical/oil-resistant outsole, EH rating | Protects against spills, acids, alkalis, and electrical hazards |

| Durability & Performance | Abrasion-resistant materials, lightweight design | Ensures boot integrity over time while minimizing energy expenditure |

Equip Your Force with Superior Footwear from 3515

As a large-scale manufacturer, 3515 produces a comprehensive range of professional and tactical footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and shoes, engineered with the advanced sole technologies detailed above.

We understand that the right boot is critical for officer safety, endurance, and performance. Partner with us to provide footwear that meets the highest standards of protection and comfort.

Contact 3515 today to discuss your specific requirements and discover how our manufacturing expertise can benefit your organization.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- How do socks affect the fit of police footwear? Optimize Your Duty Gear for Maximum Comfort

- What are station boots used for? The Essential Footwear for Firefighter Station Life

- What are the three main components of police footwear? The Anatomy of a High-Performance Duty Boot

- How can firefighters maintain their footwear? A Critical Guide to Preserving Boot Integrity & Safety

- How can officers ensure a proper fit for their police footwear? Get the Perfect Fit for Your Shift

- What are the advantages of side-zip boots? Unmatched Speed and Daily Convenience

- What are the key functions of police boots? Essential Protection, Support & Comfort for Law Enforcement

- What factors should be considered when selecting firefighting boots? Ensure Safety and Performance on the Job