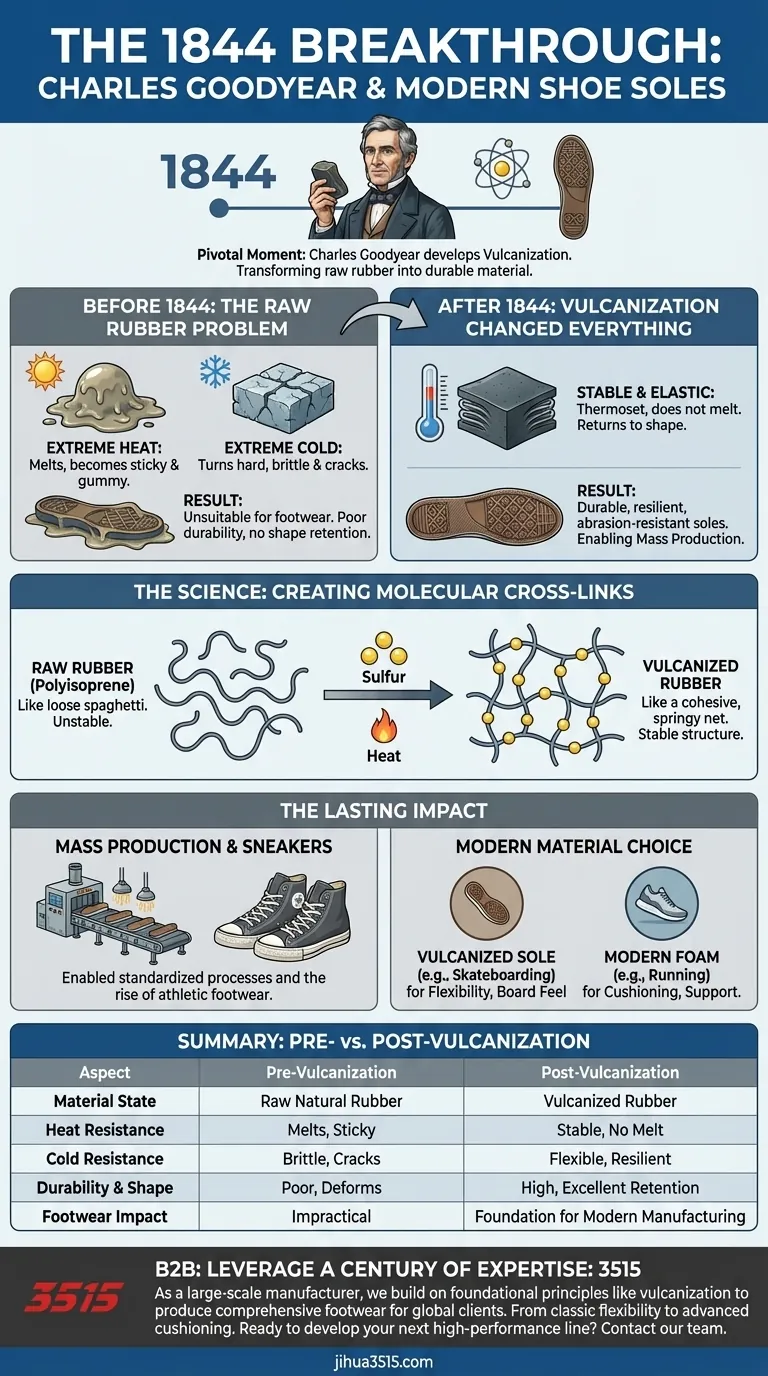

In 1844, the pivotal breakthrough was Charles Goodyear's development of the vulcanization process. This technique involves heating natural rubber with sulfur, which chemically transforms the material. This discovery directly enabled the creation of the durable, resilient, and stable rubber that forms the foundation of modern shoe soles.

The core problem with natural rubber was its instability—it would melt in the heat and become brittle in the cold. Vulcanization solved this fundamental flaw, transforming an unreliable substance into a predictable, high-performance material suitable for manufacturing.

The Problem With Raw Natural Rubber

Before 1844, natural rubber was known but had severe limitations that made it impractical for widespread use, especially in products that experienced wear and temperature changes like footwear.

Extreme Temperature Sensitivity

Raw rubber latex is a sticky, sap-like substance. When processed into a usable form without vulcanization, it remained highly susceptible to temperature.

On a hot day, it would soften, becoming gummy and sticky. In the cold, it would turn hard and brittle, easily cracking under stress.

Lack of Durability and Shape Retention

This instability meant that products made from raw rubber could not hold their shape reliably. They would deform easily and offered poor resistance to abrasion and tearing.

This made it entirely unsuitable for an application like a shoe sole, which must endure constant friction, flexing, and a wide range of environmental conditions.

How Vulcanization Changed Everything

Goodyear's process fundamentally altered the molecular structure of rubber, creating a new material with the properties we recognize today.

Creating Molecular Cross-Links

Vulcanization introduces sulfur atoms that form strong cross-links between the long polymer chains of natural rubber (polyisoprene).

Think of raw rubber as loose strands of spaghetti. Vulcanization is like adding connections that tie those strands together into a cohesive, springy net.

The Result: A Stable, Elastic Material

This cross-linked structure is what gives vulcanized rubber its key advantages. It is thermoset, meaning it no longer melts when heated.

The material becomes significantly stronger, more elastic (it returns to its original shape after being stretched), and far more resistant to abrasion. This newfound stability and durability made it the perfect material for shoe manufacturing.

The Lasting Impact on Footwear

The invention of vulcanization was not just an improvement; it was an enabling technology that created the modern footwear industry as we know it.

Enabling Mass Production

With a stable and predictable material, manufacturers could develop standardized processes for creating soles. This paved the way for the mass production of reliable, long-lasting shoes.

The Rise of the Sneaker

The process was critical to the development of athletic footwear. The combination of a flexible canvas upper bonded to a durable, vulcanized rubber sole created the first "sneakers," a design that has dominated casual and athletic footwear for over a century.

Making the Right Choice in Modern Materials

While vulcanization was the original breakthrough, its principles inform even the most advanced sole technologies today. Understanding this history helps clarify the purpose of different sole types.

- If your primary focus is tradition and board feel (e.g., skateboarding): A classic vulcanized sole remains the standard because its construction offers maximum flexibility and a direct connection to the surface.

- If your primary focus is cushioning and support (e.g., running): Modern foam compounds like EVA and PU, which offer superior shock absorption, are better suited, though their manufacturing is a direct descendant of the principles of polymer chemistry established by vulcanization.

Ultimately, Charles Goodyear's discovery in 1844 solved the fundamental material science problem that unlocked the potential of rubber for the world.

Summary Table:

| Key Aspect | Pre-Vulcanization (Before 1844) | Post-Vulcanization (After 1844) |

|---|---|---|

| Material State | Raw Natural Rubber | Vulcanized Rubber |

| Heat Resistance | Melts and becomes sticky | Stable, does not melt |

| Cold Resistance | Becomes brittle and cracks | Remains flexible and resilient |

| Durability & Shape | Poor, deforms easily | High, excellent shape retention |

| Impact on Footwear | Impractical for soles | Foundation for modern shoe manufacturing |

Leverage a Century of Manufacturing Expertise

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities, built on the foundational principles of material science like vulcanization, encompass all types of durable shoes and boots. Whether you need classic vulcanized soles for flexibility or advanced cushioning systems, we have the expertise to deliver.

Ready to develop your next line of high-performance footwear? Contact our team today to discuss your manufacturing needs and how we can bring quality and reliability to your products.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What were traditional shoe soles made from before rubber? The History of Leather Soles

- How do rubber soles affect a shoe's appearance? Defining Your Shoe's Style and Formality

- What are the advantages of rubber soles in sneakers? Unmatched Grip, Durability & Comfort

- What factors determine the slip resistance of rubber-soled shoes? Tread, Compound & Design Explained

- How do rubber and TPR soles compare in terms of water resistance? A Guide to Grip and Performance