At their core, the advantages of composite toe boots over steel toe boots center on reduced weight, superior insulation against temperature, and electrical hazard resistance. These benefits make them a specialized tool for specific environments, whereas steel toes remain the standard for maximum impact protection.

The choice between composite and steel is not about which is universally "better," but which specific set of safety features and comfort trade-offs best aligns with the demands of your unique work environment.

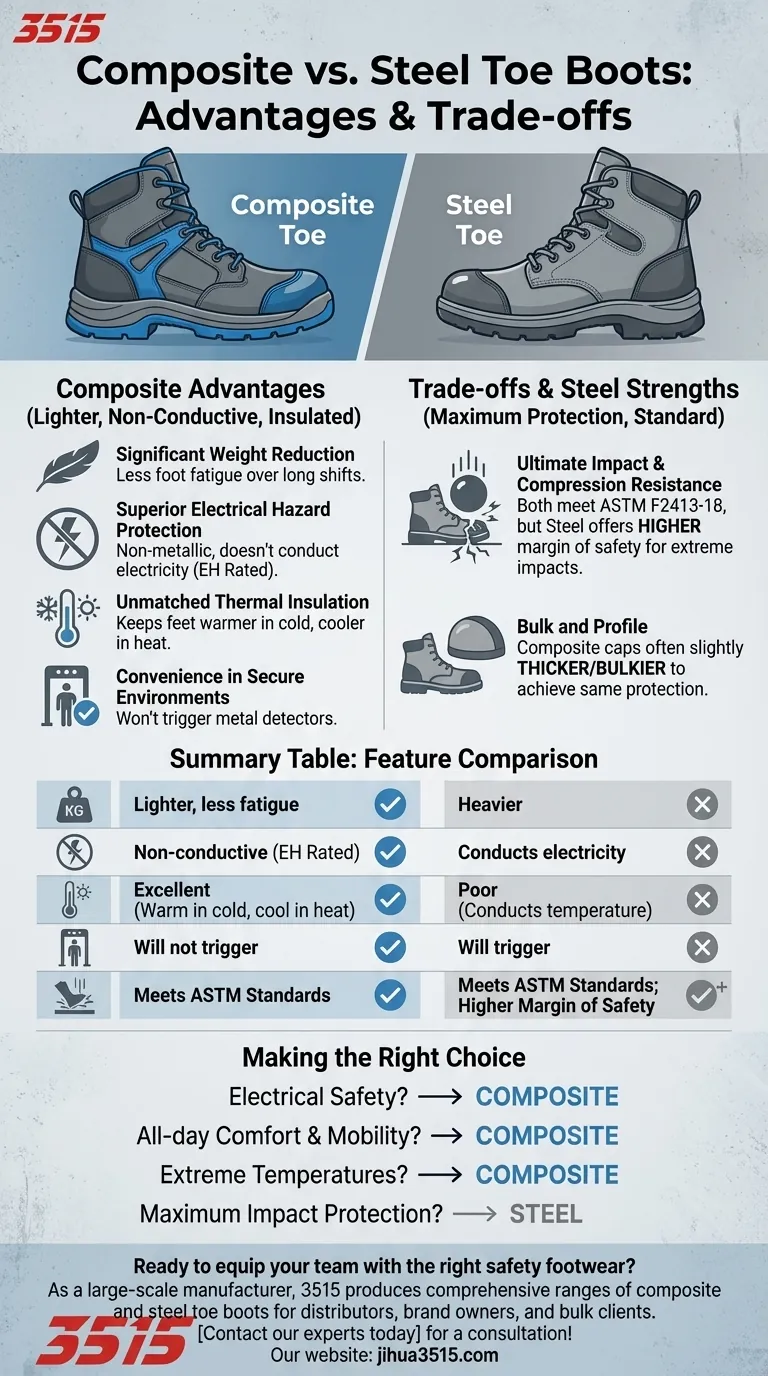

The Core Advantages of Composite Toe Boots Explained

Composite toe boots are engineered from non-metallic materials like carbon fiber, Kevlar, or specialized plastics. This construction is the source of their distinct advantages over traditional steel.

A Significant Reduction in Weight

The most noticeable difference is that composite toe boots are significantly lighter than their steel counterparts.

This weight reduction lessens foot fatigue over long work shifts, which can directly contribute to greater comfort and sustained productivity throughout the day.

Superior Electrical Hazard Protection

Because they are made from non-metallic materials, composite toe caps do not conduct electricity.

This makes them the default choice for electricians, utility workers, and anyone working in an environment where contact with live circuits is a risk. Look for an "EH" rating to ensure the entire boot is certified for this purpose.

Unmatched Thermal Insulation

Metals like steel are excellent conductors of temperature, but composite materials are not.

This means composite toe boots provide far better insulation. They help keep your feet warmer in extreme cold and cooler in intense heat, offering a significant comfort advantage in challenging weather conditions.

Convenience in Secure Environments

The non-metallic nature of composite boots offers a practical benefit for certain job sites.

They will not trigger metal detectors, making them ideal for workers who frequently pass through security checkpoints, such as in airports, nuclear plants, or secure government facilities.

Understanding the Trade-offs: Composite vs. Steel

While the advantages of composite materials are clear, it is critical to understand what you might be giving up in exchange. The primary trade-off is in the level of ultimate protection.

Impact & Compression Resistance

Both steel and composite toe boots must meet the same ASTM F2413-18 safety standards for impact and compression.

However, steel provides greater ultimate strength. In the event of an extreme impact that exceeds ASTM standards, steel is more likely to bend, whereas a composite cap may crack or shatter. For environments with a high risk of extremely heavy falling objects, steel offers a higher margin of safety.

Bulk and Profile

To achieve the same level of certified protection, a composite safety cap often needs to be slightly thicker or bulkier than a steel one.

This can sometimes affect the overall profile and fit of the boot, though modern designs have minimized this difference considerably.

Making the Right Choice for Your Goal

Select your safety footwear based on the primary hazards and daily demands of your job.

- If your primary focus is electrical safety: Composite toe boots are the non-negotiable, superior choice due to their non-conductive properties.

- If your primary focus is all-day comfort and mobility: The significant weight reduction of composite toe boots makes them an excellent option, especially if you walk long distances.

- If your primary focus is work in extreme temperatures: The thermal insulation of composite materials provides a clear advantage for keeping your feet comfortable in severe heat or cold.

- If your primary focus is maximum impact protection: Steel toe boots still offer the highest level of defense against crushing force and are the standard for heavy industrial or construction sites.

Ultimately, choosing the right boot is about accurately assessing your daily risks and choosing the specialized tool designed to counter them.

Summary Table:

| Feature | Composite Toe Boots | Steel Toe Boots |

|---|---|---|

| Weight | Lighter, less fatigue | Heavier |

| Electrical Hazard | Non-conductive (EH Rated) | Conducts electricity |

| Thermal Insulation | Excellent (Warm in cold, cool in heat) | Poor (Conducts temperature) |

| Metal Detectors | Will not trigger | Will trigger |

| Ultimate Impact Protection | Meets ASTM Standards | Meets ASTM Standards; Higher Margin of Safety |

Ready to equip your team with the right safety footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of composite and steel toe boots for distributors, brand owners, and bulk clients. We can help you select the perfect boot for your specific work environment, ensuring optimal safety, comfort, and compliance.

Contact our experts today for a consultation and to discuss your bulk footwear needs!

Visual Guide

Related Products

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- What are the protective functions of industrial safety boots in sugar factory clarification stations? Thermal & Slip Experts

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- Why is the anti-smash feature essential in palm oil processing areas? Ensure Worker Safety from Heavy Machinery Risks

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- How do Robotic Gait Systems verify the durability and safety of mass-produced safety boots? Ensure Unrivaled Performance in Extreme Conditions