At its core, Blake Stitching is a shoe construction method known for its exceptional flexibility, sleek profile, and more accessible price point. It achieves this by stitching the shoe's upper directly to the sole from the inside, creating a simple, durable bond that is a significant upgrade from basic glued construction.

The primary advantage of a Blake Stitched shoe is achieving a high degree of comfort and a close-cut, elegant look. It represents a valuable middle ground between mass-market cemented shoes and more complex, expensive construction methods.

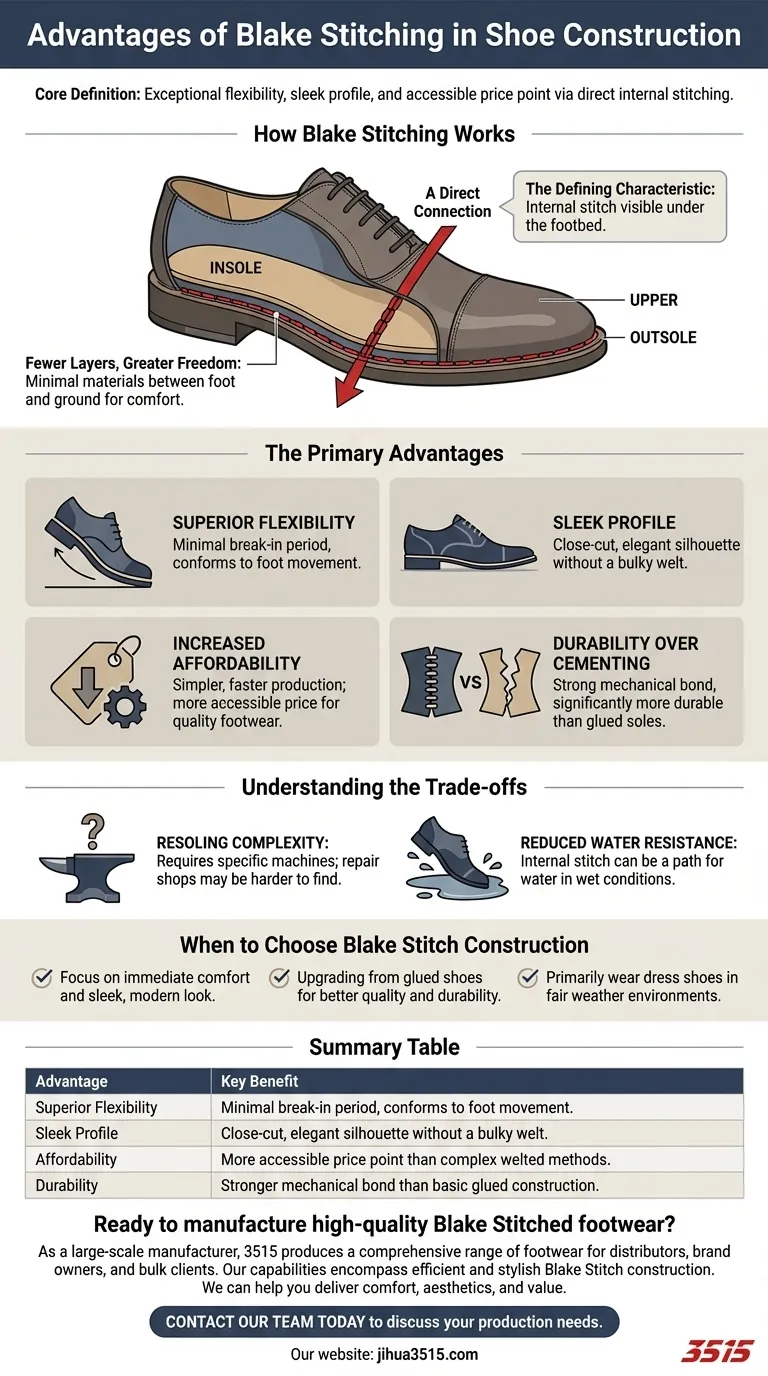

How Blake Stitching Works

To appreciate its advantages, you must first understand its distinct architecture. Unlike other methods, the Blake Stitch is defined by its directness and simplicity.

A Direct Connection

The process uses a specialized machine to pass a single stitch directly through the shoe's insole, the upper, and the outsole. This creates a single, strong seam that holds the entire shoe together.

This internal stitch is the defining characteristic of the method. If you look inside the shoe and lift the footbed, you will see the line of stitching that runs around the perimeter.

Fewer Layers, Greater Freedom

Because the upper is attached directly to the sole, there are fewer layers of material—like a welt or cork filling—between your foot and the ground. This minimalist construction is the source of its key benefits.

The Primary Advantages Explained

The simple, direct construction of the Blake Stitch translates into tangible benefits for the wearer, focusing on comfort, aesthetics, and cost.

Superior Flexibility

The most immediate advantage is flexibility. With fewer rigid layers, a Blake Stitched shoe feels more pliable and requires virtually no break-in period, conforming to your foot's movement almost immediately.

A Sleeker Profile

The lack of an external welt allows the outsole to be trimmed very close to the upper. This results in a shoe with a sleek, close-cut silhouette that is often seen as more elegant and less chunky than its Goodyear-welted counterparts.

Increased Affordability

The construction process is simpler and faster than more labor-intensive methods like the Goodyear welt. This efficiency reduces manufacturing costs, making Blake Stitched shoes a more affordable entry into high-quality, resoleable footwear.

Durability Over Cementing

While not the most robust method available, a Blake Stitch is significantly stronger and more durable than having the sole simply glued on (also known as cementing). The stitch provides a secure mechanical bond that is far less likely to fail or separate.

Understanding the Trade-offs

No construction method is perfect for every situation. Objectivity requires acknowledging where the Blake Stitch makes compromises.

Resoling Complexity

A Blake Stitched shoe can be resoled, but it requires a specific Blake Stitch machine that not all cobblers possess. This makes finding a qualified repair shop more difficult compared to the near-universal serviceability of a Goodyear welt.

Reduced Water Resistance

The stitch that runs through the outsole directly into the shoe's interior can act as a channel for water. This makes Blake Stitched footwear less suitable for consistently wet environments compared to welted constructions that create a more effective barrier.

When to Choose Blake Stitch Construction

Your ideal choice depends entirely on your priorities and intended use for the footwear.

- If your primary focus is immediate comfort and a sleek, modern look: The flexibility and close-cut profile of a Blake Stitch are perfectly suited for your needs.

- If you are upgrading from glued shoes: A Blake Stitched shoe offers a significant leap in quality and durability without the higher price of a Goodyear welt.

- If you primarily wear dress shoes in fair weather: The limited water resistance is a non-issue, allowing you to enjoy all the aesthetic and comfort benefits.

Ultimately, choosing a Blake Stitched shoe is an excellent decision when you value flexibility and style in a well-made, resoleable package.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Superior Flexibility | Minimal break-in period, conforms to foot movement. |

| Sleek Profile | Close-cut, elegant silhouette without a bulky welt. |

| Affordability | More accessible price point than complex welted methods. |

| Durability | Stronger mechanical bond than basic glued construction. |

Ready to manufacture high-quality Blake Stitched footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including the efficient and stylish Blake Stitch construction.

We can help you deliver the comfort, sleek aesthetics, and value your customers are looking for. Contact our team today to discuss your production needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards