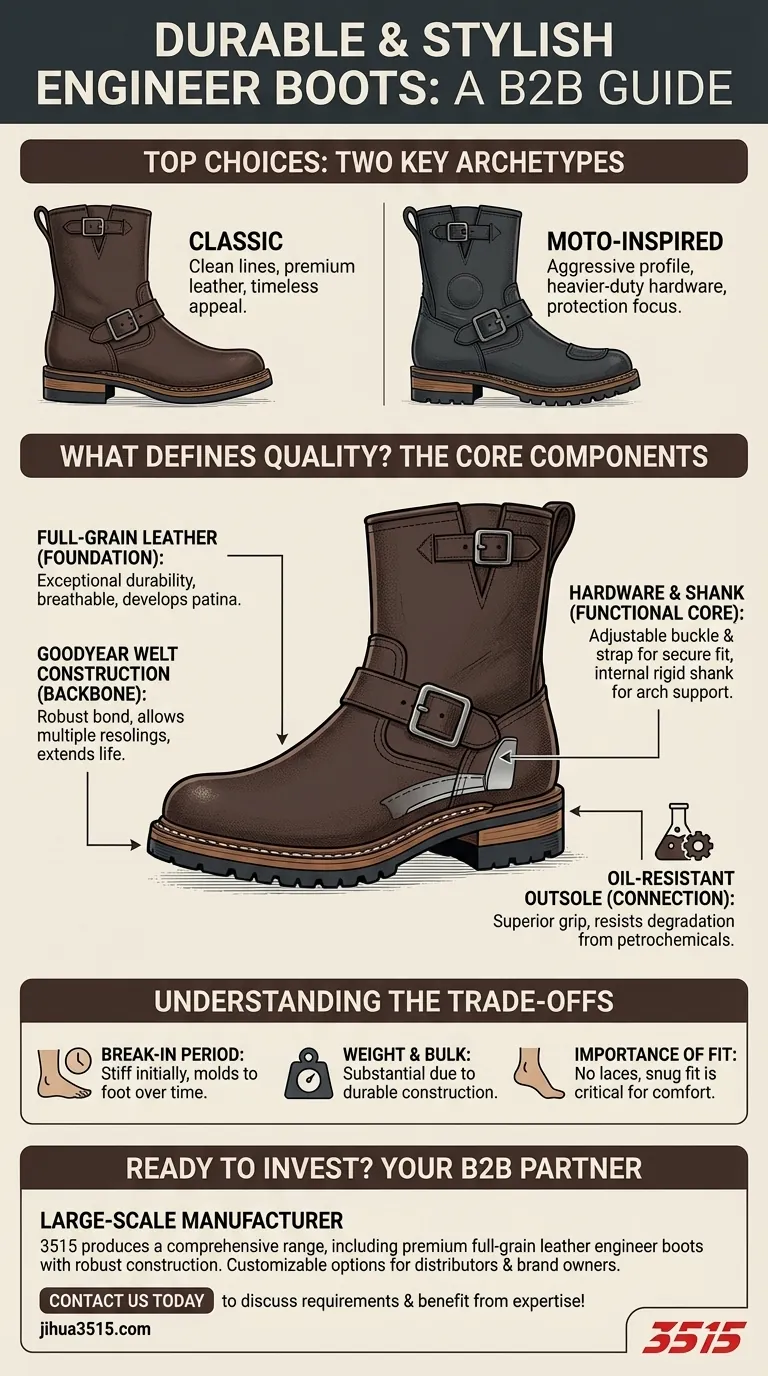

The top choices for durable and stylish engineer boots are less about specific brands and more about archetypes that prioritize either classic style or rugged function. For timeless appeal, look for a "Classic" configuration featuring clean lines and premium leather. For a more aggressive, motorcycle-ready option, a "Moto" boot with heavier-duty hardware and a focus on protection is the superior choice.

The true mark of a superior engineer boot isn't the name on the side, but the quality of its core components. Understanding the roles of full-grain leather, Goodyear welt construction, and functional hardware is the key to choosing a boot that is both durable and stylish for years to come.

What Truly Defines a Quality Engineer Boot?

To find a genuinely durable and stylish boot, you must look past surface-level aesthetics and evaluate its fundamental construction. These core features separate a long-term investment from a short-term fashion piece.

The Foundation: Premium Full-Grain Leather

Full-grain leather is the highest quality grade available. It comes from the top layer of the hide and includes all the natural grain.

This makes it exceptionally durable, breathable, and capable of developing a rich patina over time. It is the essential material for a boot designed to last decades.

The Backbone: Goodyear Welt Construction

The Goodyear welt is a time-tested method of attaching the boot's upper to the sole. A strip of leather (the "welt") is stitched around the bottom edge of the upper and to the insole.

This construction creates an incredibly robust bond and, most importantly, allows the boot to be resoled multiple times, dramatically extending its usable life.

The Functional Core: Hardware and Support

Engineer boots are defined by their lack of laces. Fit and security are managed by an adjustable leather strap and buckle across the ankle.

A second buckle is often found at the top of the shaft to adjust the fit around the calf. Internally, a rigid shank is critical for distributing weight and providing arch support during long periods of wear.

The Outsole: Your Connection to the Ground

The outsole must be as durable as the rest of the boot. Look for thick, hard-wearing rubber compounds.

For work or motorcycling, an oil-resistant sole provides superior grip and prevents the material from degrading when exposed to petrochemicals.

The Intersection of Style and Functionality

The engineer boot's appeal comes from its bold, functional design. Its heritage as a work and motorcycle boot informs its timeless style.

The Classic Profile

The traditional engineer boot features a tall shaft, typically 10-12 inches, a plain, rounded toe, and minimal ornamentation.

This clean, commanding silhouette pairs surprisingly well with a range of outfits, from rugged denim to more refined wool trousers.

The Moto-Inspired Variant

Many modern engineer boots lean into their motorcycling roots. These often feature a more aggressive profile, heavier-duty buckles, and sometimes reinforced toe or shifter pads.

While still stylish, these boots place a higher premium on protection and a rugged aesthetic.

How to Wear Them Effectively

The key to styling engineer boots is managing their height and bulk. Your trousers should be wide enough to fit comfortably over the boot's shaft.

Avoid tucking your jeans into the boots. Instead, cuff your pants slightly higher than usual to showcase the boot's distinctive buckle and silhouette without disrupting the line.

Understanding the Trade-offs

The features that make engineer boots so durable also introduce practical considerations you must be aware of before purchasing.

The Inevitable Break-in Period

High-quality, thick full-grain leather is stiff when new. Expect a significant break-in period as the leather and sole mold to the unique shape of your foot.

The Weight and Bulk

A Goodyear welt, a thick leather upper, a shank, and a heavy-duty outsole result in a substantial boot. These are not lightweight footwear; their weight is a direct consequence of their durable construction.

The Importance of a Perfect Fit

The absence of laces means you cannot fine-tune the fit across your instep. Trying boots on and ensuring a snug—but not tight—fit from the start is absolutely critical for long-term comfort.

Selecting the Right Boot for Your Purpose

Your final choice should be guided by your primary reason for wanting the boots.

- If your primary focus is timeless style: Prioritize a classic profile with premium, full-grain leather that will age beautifully and a standard Goodyear welt for longevity.

- If your primary focus is maximum durability for work or riding: Emphasize a rugged, oil-resistant outsole, a strong internal shank for support, and thick leather that prioritizes protection over immediate comfort.

- If your primary focus is a balance of comfort and function: Pay extra attention to the initial fit and consider boots with a quality leather lining to help manage moisture and reduce friction during the break-in period.

Ultimately, choosing the right engineer boot is an investment in quality craftsmanship that will serve you well for years.

Summary Table:

| Feature | Purpose | Benefit |

|---|---|---|

| Full-Grain Leather | Foundation material | Exceptional durability, breathability, and rich patina over time |

| Goodyear Welt Construction | Attaches upper to sole | Allows resoling, extends boot life significantly |

| Adjustable Buckle & Strap | Replaces laces for fit | Secure ankle support, defines engineer boot style |

| Oil-Resistant Outsole | Ground contact layer | Superior grip, resists degradation from petrochemicals |

| Internal Shank | Arch support | Distributes weight, provides stability for long wear |

Ready to invest in durable, stylish engineer boots tailored to your needs? As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including engineer boots built with premium full-grain leather and robust construction techniques. Whether you prioritize classic style or rugged functionality, we deliver high-quality, customizable options that combine longevity with aesthetic appeal. Contact us today to discuss your requirements and benefit from our expertise in crafting footwear that stands the test of time!

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What is a moc toe boot? A Guide to the Iconic Workwear & Casual Staple

- Why is hydrophobic waterproof leather commonly utilized in the construction of fire safety boots? Essential Protection

- Can heavy duty work boots be resoled? Maximize Your Boot's Lifespan & Value

- What alternative footwear options are suggested for winter biking? Save Money on Warm Winter Boots

- What types of protective footwear are available for jobs with electrical hazards? EH vs. SD Boots Explained

- How should one choose the right type of safety boots for their job? A Step-by-Step Guide

- Why is Goodyear welt construction preferred for work boots? For Unmatched Durability & Repairability

- What are the disadvantages of synthetic/leather boots? The Long-Term Value Trade-Off