Yes, most high-quality heavy-duty work boots are specifically designed to be resoled. The ability to replace a worn-out sole is a key feature of premium footwear, allowing you to extend the life of your investment significantly. The determining factor is not the brand, but the construction method used to attach the sole to the boot's upper.

The core issue isn't whether a boot can be resoled, but whether it was built to be resoled. Understanding the difference between a stitched construction and a disposable cemented one is the key to maximizing the long-term value of your work boots.

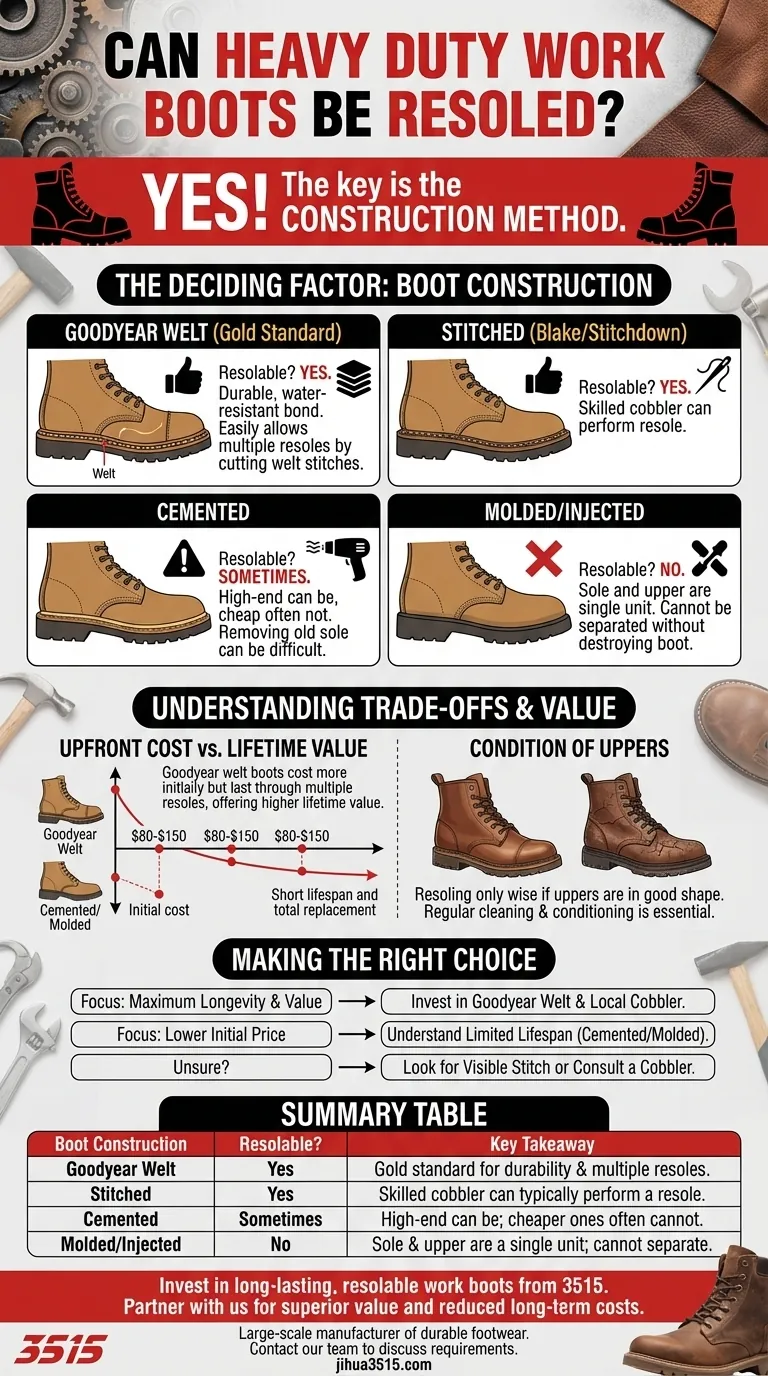

The Deciding Factor: Boot Construction

How a boot is put together dictates whether a cobbler can cleanly remove the old sole and attach a new one. There are a few primary methods you will encounter.

Goodyear Welt Construction

This is the gold standard for durable, resolable footwear. A leather strip, called a welt, is stitched to the boot's upper. The outsole is then stitched to this welt.

This creates a highly durable and water-resistant bond. Most importantly, it allows a cobbler to remove the old outsole by simply cutting the welt stitches, leaving the upper completely intact and ready for a new sole.

Stitched Construction (Blake/Stitchdown)

Other stitched methods, like Blake or Stitchdown, also allow for resoling. While less common in heavy-duty work boots than a Goodyear welt, they involve stitching the sole components together.

A skilled cobbler can readily identify these methods and perform a resole, though the process may be slightly different.

Cemented Construction

In this method, the sole is attached to the upper using a strong industrial adhesive. Many modern boots, including some high-quality synthetic models, use this technique.

High-end cemented boots can often be resoled by a skilled professional who can properly heat and remove the old sole. However, cheaper boots often use a low-quality cement bond that makes a clean removal nearly impossible without damaging the boot.

Molded or Injected Soles: The Exception

This is the construction method that typically cannot be resoled. The sole, usually made of rubber or polyurethane, is chemically bonded or injected directly onto the upper as a single unit.

Attempting to remove this type of sole will destroy the boot, as there is no clear separation between the sole and the upper. These boots are designed to be discarded once the tread wears out.

Understanding the Trade-offs

Choosing a resolable boot involves balancing upfront costs with long-term benefits.

Upfront Cost vs. Lifetime Value

Boots with a Goodyear welt construction are almost always more expensive upfront due to the skilled labor and materials involved.

However, their lifetime value is significantly higher. A single pair of high-quality uppers can last through two, three, or even more resoles, making the total cost of ownership lower over time.

The Cost of a Resole

A professional resole for a pair of work boots typically costs between $80 and $150, depending on the cobbler's skill, your location, and the type of sole you choose.

When you compare this to the $200-$400+ cost of a new pair of premium boots, the financial benefit is clear.

The Condition of the Uppers

Resoling is only a wise investment if the boot's uppers are in good shape. If the leather or synthetic material is cracked, torn, or severely damaged, the boot has reached the end of its functional life.

Regular cleaning and conditioning of the uppers is essential to ensure they outlast the original sole.

Making the Right Choice for Your Investment

Use this framework to guide your purchasing and maintenance decisions.

- If your primary focus is maximum longevity and value: Invest in work boots built with a Goodyear welt construction and partner with a local cobbler.

- If your primary focus is a lower initial purchase price: Understand that boots with cemented or directly injected soles may have a fixed lifespan and are unlikely to be resolable.

- If you are unsure about your current boots: Look for a visible stitch running around the top edge of the sole, which indicates a welt. For a definitive answer, take them to a reputable cobbler for a professional assessment.

Ultimately, choosing a resolable work boot transforms it from a disposable item into a long-term piece of essential equipment.

Summary Table:

| Boot Construction | Resolable? | Key Takeaway |

|---|---|---|

| Goodyear Welt | Yes | Gold standard for durability and multiple resoles. |

| Stitched (Blake/Stitchdown) | Yes | A skilled cobbler can typically perform a resole. |

| Cemented | Sometimes | High-end boots can be resoled; cheaper ones often cannot. |

| Molded/Injected | No | Sole and upper are a single unit; cannot be separated. |

Invest in long-lasting, resolable work boots from 3515.

As a large-scale manufacturer, we produce a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of work boots and shoes, including those built with longevity in mind.

Partner with us to offer your customers superior value and reduce their long-term costs. Contact our team today to discuss your requirements and request a catalog.

Visual Guide

Related Products

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- High Performance Fire-Retardant Waterproof Safety Boots

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What are some advanced technologies used in oilfield boots? Discover the Systems Protecting Workers

- How do pull on work boots accommodate wider feet or higher insteps? Discover the Ultimate Comfort Fit

- What should delivery drivers look for in work shoes? Essential Features for Safety & Comfort

- What should be done before wearing new work boots for the first time? A 3-Step Guide for Optimal Fit & Durability

- Which occupations typically prefer steel toe boots? Essential Safety for High-Risk Jobs

- What are the important characteristics for work boot soles? Match the Sole to Your Job for Safety & Comfort

- Are there any exceptions to the sole requirement for wildland fire boots? The Alaskan Exemption Explained

- What were the original purposes of cowboy boots? A Tool for Safety and Function on the Range