Breaking in new tactical boots is a non-negotiable process that methodically molds them to your feet, preventing injury and ensuring reliability. The most effective strategy is to begin by wearing them for short periods around the house, then gradually increasing the duration and intensity of use outdoors, always pairing them with high-quality, moisture-wicking socks.

The objective is not merely to soften stiff materials, but to create a custom fit that eliminates painful hot spots and ensures your boots provide stable, comfortable support when you need it most.

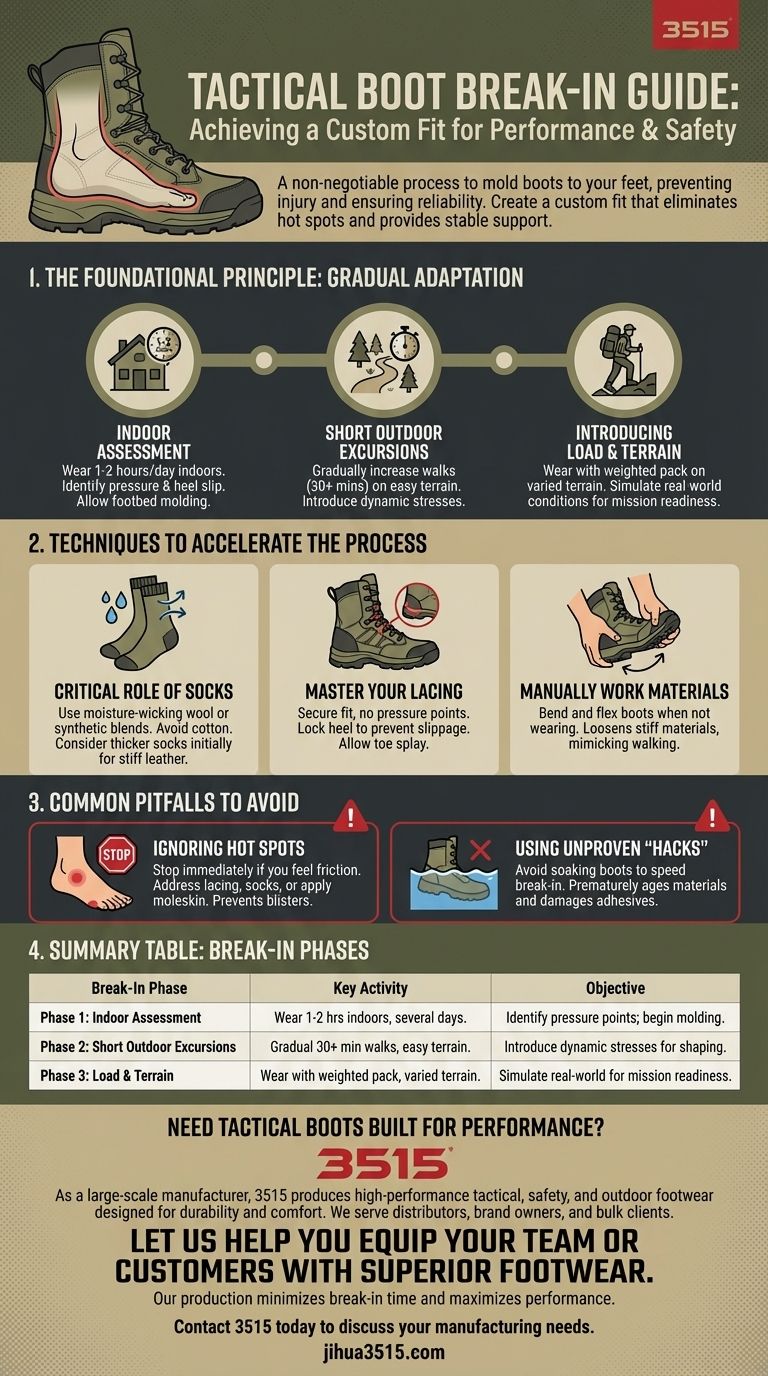

The Foundational Principle: Gradual Adaptation

Rushing the break-in period is the single most common cause of blisters, chafing, and foot fatigue. The key is to allow both the boot materials and your feet time to adapt to each other through a phased approach.

Phase 1: The Indoor Assessment

Start by wearing your new boots indoors for one to two hours at a time over several days. This controlled environment allows you to identify potential issues without serious consequences.

Walk around your house, go up and down stairs, and stand in them for extended periods. This helps the boot's footbed begin to conform to the shape of your foot.

Pay close attention to any pinching, excessive pressure, or areas where your heel slips. Minor discomfort is normal, but sharp pain is a sign of a poor fit.

Phase 2: Short Outdoor Excursions

Once the boots feel relatively comfortable indoors, begin wearing them for short walks outside on pavement or easy trails. Start with 30-minute walks and gradually increase the time.

This introduces the dynamic stresses of walking on varied surfaces, further shaping the boot. It also reveals how your feet respond to heat and friction over a longer duration.

Phase 3: Introducing Load and Terrain

For tactical use, boots must be comfortable under load. After succeeding with short walks, wear the boots on more challenging terrain or while carrying a weighted pack.

This final phase simulates the real-world conditions the boots were designed for. It is the ultimate test to ensure they are fully broken-in and mission-ready.

Techniques to Accelerate the Process

While time is the primary factor, several techniques can help expedite the break-in period and improve the final fit.

The Critical Role of Socks

The socks you wear are as important as the boots themselves. Always use moisture-wicking socks made of wool or a synthetic blend.

Cotton socks retain moisture, which softens the skin and dramatically increases the risk of blisters and friction sores.

For particularly stiff leather boots, wearing a slightly thicker sock (or a double sock layer) during the initial indoor phase can help stretch the material more effectively.

Master Your Lacing

Experiment with different lacing techniques. The goal is a secure fit that doesn't cut off circulation or create pressure points.

Your lacing should lock your heel into the back of the boot to prevent slippage, which is a primary cause of blisters. However, it should still allow enough room for your toes to splay naturally.

Manually Work the Materials

When you're not wearing the boots, take a few minutes to manually bend and flex them, especially around the ankle and the ball of the foot.

This repeated motion helps loosen stiff leather or synthetic fibers, mimicking the effect of walking and accelerating the softening process.

Common Pitfalls to Avoid

Understanding what not to do is crucial for a successful break-in and for protecting your investment in high-quality footwear.

Ignoring Hot Spots

A "hot spot" is a localized area of friction or pressure that will eventually become a blister. The moment you feel one, stop.

Remove your boot, check your foot, and address the issue. This may involve adjusting your lacing, changing your socks, or applying moleskin or athletic tape to the affected area. Pushing through it will only lead to injury.

Using Unproven "Hacks"

Avoid shortcuts like soaking your boots in water and wearing them until they dry. While some methods have anecdotal support, they can also prematurely age or damage the boot's materials, especially leather, and ruin adhesives.

The gradual wear method is the safest and most reliable approach recommended by manufacturers and seasoned professionals.

Making the Right Choice for Your Goal

Your specific goal dictates the intensity and focus of the break-in process.

- If your primary focus is daily duty wear: Prioritize consistency, wearing the boots for a few hours each day for one to two weeks to achieve all-day comfort.

- If you are preparing for a long ruck or field exercise: You must integrate sessions with a weighted pack on varied terrain to ensure the boots perform under load.

- If you are dealing with exceptionally stiff all-leather boots: Be patient and place extra emphasis on manually flexing the material and using thicker socks during the initial indoor phase.

A properly broken-in pair of tactical boots is a fundamental tool for performance and safety.

Summary Table:

| Break-In Phase | Key Activity | Objective |

|---|---|---|

| Phase 1: Indoor Assessment | Wear boots 1-2 hours indoors for several days. | Identify pressure points; begin footbed molding. |

| Phase 2: Short Outdoor Excursions | Gradual 30+ minute walks on easy terrain. | Introduce dynamic stresses for further shaping. |

| Phase 3: Load & Terrain | Wear boots with a weighted pack on varied terrain. | Simulate real-world conditions for mission readiness. |

Need Tactical Boots Built for Performance?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance tactical, safety, and outdoor footwear designed for durability and comfort right out of the box. We understand the importance of a reliable fit for distributors, brand owners, and bulk clients who demand the best for their end-users.

Let us help you equip your team or customers with superior footwear. Our production capabilities encompass all types of boots engineered to minimize break-in time and maximize performance.

Contact 3515 today to discuss your manufacturing needs and discover how our expertise can benefit your business.

Visual Guide

Related Products

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- Why is conditioning important for full grain leather tactical boots? Prevent Cracking & Ensure Longevity

- What does the upper part of a tactical boot cover? Your Guide to Protection, Fit, and Performance

- What features enhance breathability and comfort in tactical boots? A Guide to Superior Footwear Performance

- How has tactical footwear evolved over time? From Heavy Leather to Lightweight Performance

- What is the application potential of biomimetic S-shaped spider web composites in high-performance safety footwear and tactical boots? Next-Gen Impact Protection

- What is the application value of polyurethane elastomers? Enhance Safety Shoes and Tactical Boots with High-Tech Soles

- What are the structural advantages of durable tactical boots? Elevate Performance in Rugged & Non-Standard Terrains

- Why is footwear important in tactical situations? A Foundation for Mission Success