When your shoes offer more slip than grip, you need an immediate solution. The most common temporary hacks involve increasing the sole's friction, which you can do by scuffing the bottom with sandpaper, applying a layer of hairspray for tackiness, or using traction sprays designed for this purpose. These methods work by altering the texture of the sole to create a rougher, more adhesive surface.

While temporary fixes can provide a short-term increase in grip, they are not a substitute for the engineered safety of a proper non-slip sole. The real solution lies in understanding what creates reliable traction and recognizing the limitations of any quick-fix method.

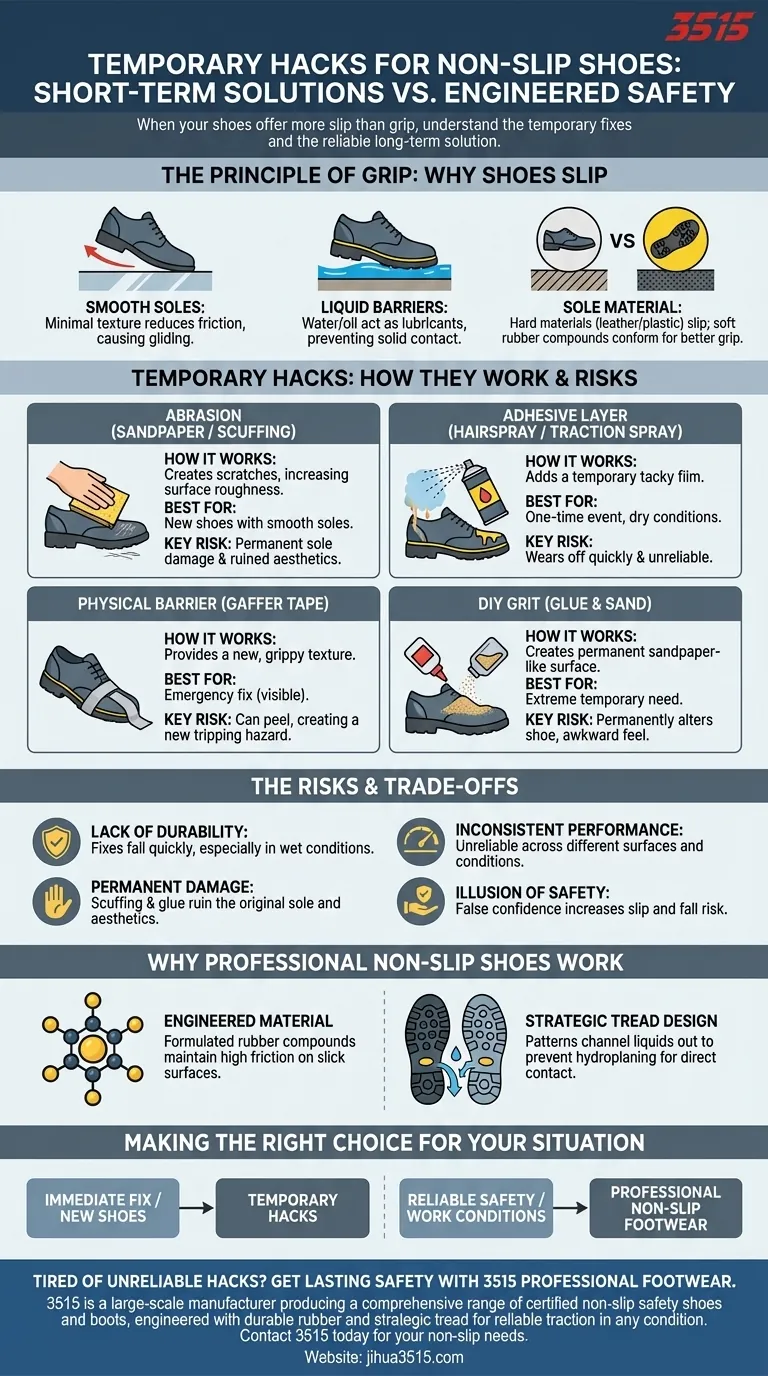

The Principle of Grip: Why Shoes Slip

To solve the problem of slipping, we first need to understand the forces at play. Traction is a function of friction, and a loss of traction occurs when that friction is compromised.

The Problem with Smooth Soles

A brand-new shoe, particularly a dress shoe with a leather or composite sole, is perfectly smooth. This minimal texture reduces the coefficient of friction, allowing it to glide easily over surfaces, which is precisely what you don't want.

The Impact of Liquid

Even a microscopic layer of water, oil, or dust can act as a lubricant between your shoe and the floor. This barrier prevents the two surfaces from making solid contact, causing you to hydroplane and lose your footing.

How Sole Material Matters

The material of the sole is a critical factor. Hard, inflexible materials like leather or cheap plastic have less give and are more prone to slipping. Softer rubber compounds can better conform to microscopic imperfections in the floor, maximizing surface contact and grip.

A Breakdown of Temporary Fixes

Each temporary hack attempts to solve the friction problem in a slightly different way. Their effectiveness and durability vary significantly.

Increasing Friction Through Abrasion

Methods like scuffing the soles on rough concrete or using a piece of sandpaper work on a simple principle. They create thousands of tiny scratches and grooves on the sole, dramatically increasing its surface roughness and ability to create friction.

Applying an Adhesive Layer

Using hairspray or a dedicated traction spray adds a sticky, tacky film to the bottom of your shoes. This adhesive quality provides an immediate but very temporary boost in grip, acting like a light glue between your sole and the floor.

Creating a Physical Barrier

Applying gaffer tape or even band-aids in a pinch introduces a new material with a different texture. The woven fabric of the tape can offer more grip than a smooth sole, but this method is visually obvious and not very durable.

The DIY Grit Method

A more extreme and permanent hack involves applying glue and sprinkling it with sand. This essentially creates a custom, sandpaper-like surface on your soles. While effective, it permanently alters the shoe and can feel awkward to walk on.

Understanding the Trade-offs and Risks

Before you modify your shoes, it is critical to understand the downsides. These hacks are not professionally engineered solutions and come with inherent risks.

Lack of Durability

Hairspray can wear off in a matter of hours, or even minutes, on a wet day. Tape can peel off unexpectedly, potentially creating a new tripping hazard mid-stride. These fixes are fundamentally unreliable for all-day use.

Potential for Permanent Damage

Scuffing, sanding, and especially the glue-and-sand method will permanently damage your shoe's original sole. This can ruin the aesthetic of the shoe and may lead to it wearing out unevenly and more quickly.

Inconsistent Performance

A hack that works well on dry tile might fail completely on a wet or greasy surface. Unlike professionally designed shoes, these methods are not tested for performance across different conditions, making their effectiveness unpredictable when you need it most.

The Illusion of Safety

Perhaps the biggest risk is a false sense of security. Believing your shoes are "fixed" might cause you to walk with less caution, paradoxically increasing your risk of a slip and fall when the temporary solution inevitably fails.

Why Professional Non-Slip Shoes Work

Certified non-slip footwear is not just about having a rubber sole. It is an engineered system designed for safety and reliability.

Engineered Sole Material

True non-slip shoes use a soft but highly durable rubber compound. This material is specifically formulated to maintain a high coefficient of friction even on slick surfaces, providing a consistent and dependable grip.

Strategic Tread Design

The pattern on the bottom of the shoe is not for style. Tread patterns, often using hexagons or circles, are designed to channel water and other liquids out from under the sole. This prevents hydroplaning and allows the rubber to make direct contact with the floor, which is the key to maintaining traction in wet conditions.

Making the Right Choice for Your Situation

Your approach should match the level of risk you face.

- If you need an immediate, one-time fix: Using hairspray or lightly scuffing your soles on pavement can work for a single event where aesthetics are key.

- If you frequently wear new shoes with smooth soles: Lightly abrading the soles with medium-grit sandpaper before the first wear is an effective way to "break them in" and remove the slick factory finish.

- If your safety depends on reliable traction (e.g., at work): Temporary hacks are entirely inappropriate. Investing in footwear with a certified non-slip rating is the only responsible choice to protect yourself from injury.

Ultimately, true stability comes not from a temporary fix, but from choosing the right foundation for the conditions you face.

Summary Table:

| Temporary Hack | How It Works | Best Use Case | Key Risk |

|---|---|---|---|

| Sandpaper / Scuffing | Creates surface roughness for friction | New shoes with smooth soles | Permanent sole damage |

| Hairspray / Traction Spray | Adds a temporary sticky layer | One-time event, dry conditions | Wears off quickly, unreliable |

| Gaffer Tape | Provides a new, grippy texture | Emergency fix, visible is okay | Can peel, creating a tripping hazard |

| Glue & Sand | Creates a permanent gritty surface | Extreme need for grip | Permanently alters shoe, awkward feel |

Tired of unreliable temporary fixes? Get lasting safety and comfort with professional footwear from 3515.

As a large-scale manufacturer, 3515 produces a comprehensive range of certified non-slip footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, engineered with durable rubber compounds and strategic tread patterns for reliable traction in any condition.

Contact 3515 today to discuss your non-slip footwear needs and ensure true, dependable safety for your team or customers.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

People Also Ask

- Why are industrial-grade safety shoes mandatory in metallurgical workshops? Essential Protection for Extreme Environments

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now

- Why does the material performance of professional slip-resistant shoes offer superior safety? Hardware vs. Behavior

- Why is it mandatory to wear safety shoes with steel toe protection during metal loading? Prevent Crushing Injuries

- What is the purpose of requiring subjects to wear anti-slip socks and tight-fitting sportswear? Optimize Sensor Data