CORDURA is not a single fabric, but a comprehensive family of constructions ranging from ultra-light 30 denier ripstop to heavy-duty 1050 denier ballistic nylon. Available variations include nylon/cotton blends, textured nylon and polyester packcloths (300, 500, and 1000 denier), and specialized bottom weights like 160 and 330 denier.

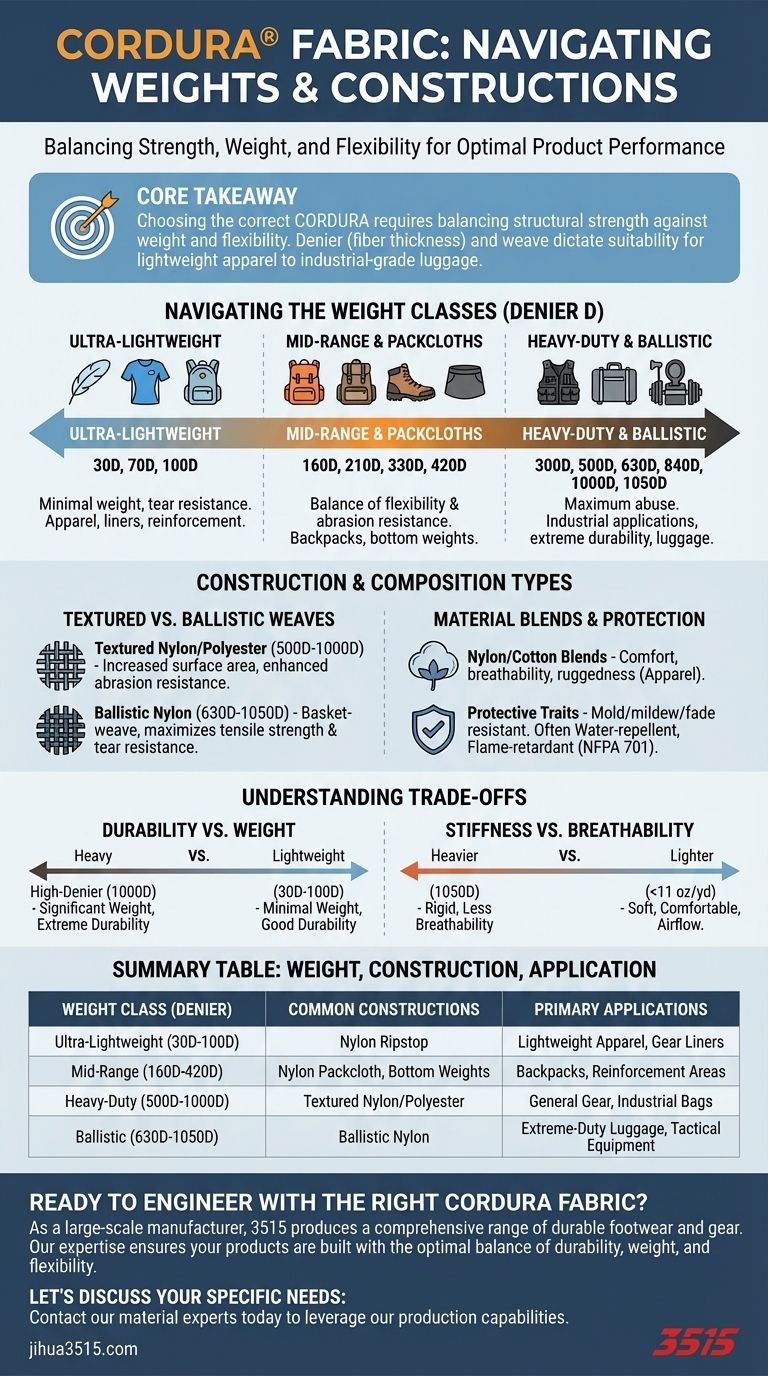

Core Takeaway Choosing the correct CORDURA fabric requires balancing structural strength against weight and flexibility. While all variations offer superior durability compared to standard nylon and polyester, the specific denier (fiber thickness) and weave construction determine whether the material is best for lightweight apparel or industrial-grade luggage.

Navigating the Weight Classes (Denier)

The most critical specification to understand is denier (D), which measures the linear mass density of fibers. A higher number indicates a heavier, thicker fiber.

Ultra-Lightweight Options

For applications requiring minimal weight, CORDURA offers nylon ripstop in 30, 70, and 100 denier.

These fabrics are designed to provide tear resistance without the bulk associated with traditional tactical gear. They are often used in apparel or as reinforcement zones in lightweight equipment.

Mid-Range and Packcloths

The mid-range category balances flexibility with significant abrasion resistance. This includes lightweight nylon packcloths in 210 and 420 denier.

Additionally, "bottom weights"—often used for the base of bags or reinforcement areas—are available in 160 and 330 denier.

Heavy-Duty and Ballistic

For maximum abuse, the portfolio includes textured nylon or polyester packcloths in 300, 500, and 1000 denier.

At the extreme end of the spectrum are the heavyweight nylon ballistic fabrics. These come in weights of 630, 840, and 1050 denier, specifically engineered for industrial applications, luggage, and environments requiring extreme durability.

Construction and Composition Types

Beyond simple weight, the method of construction and the fiber blend dictate the fabric's performance profile.

Textured vs. Ballistic Weaves

Textured nylon and polyester are common in the 500D to 1000D range. The texturing process increases the surface area, enhancing abrasion resistance.

Ballistic nylon (630D–1050D) utilizes a specific basket-weave construction. Originally developed for military use—historically even for tire construction—this weave maximizes tensile strength and tear resistance.

Material Blends

While pure nylon is standard for high-strength needs, nylon/cotton blends are available. These are typically used to improve comfort and breathability in apparel while maintaining a degree of ruggedness.

Protective Characteristics

Regardless of the specific weight, CORDURA fabrics generally share core protective traits. They are resistant to mold, mildew, and fading.

Many constructions also feature water-repellent and flame-retardant properties, with specific lines complying with National Fire Protection Agency (NFPA) 701 guidelines.

Understanding the Trade-offs

While CORDURA is marketed on its strength, selecting the heaviest option is not always the correct engineering decision.

Durability vs. Weight

CORDURA is exceptionally durable—cited as 2 times more durable than standard nylon and 3 times more durable than standard polyester.

However, high-denier fabrics (like 1000D) add significant weight to the end product. For contexts like hiking or mobile tactical operations, the weight penalty of ballistic nylon may outweigh the durability benefits.

Stiffness and Breathability

Heavier weights (1050D) are rigid and offer less breathability.

Conversely, lighter weights (approx. 11 ounces per yard or lower) offer softness, comfort, and airflow. You must sacrifice some absolute abrasion resistance to gain the flexibility required for clothing or ergonomic gear.

Making the Right Choice for Your Goal

To select the right construction, you must isolate the primary failure point you are trying to prevent.

- If your primary focus is extreme durability (Luggage/Industrial): Opt for 1000D textured nylon or 1050D ballistic nylon to maximize abrasion and tear resistance where weight is a secondary concern.

- If your primary focus is balance (Backpacks/General Gear): Choose 500D textured nylon, which offers the industry-standard "sweet spot" between high durability and manageable weight.

- If your primary focus is mobility (Apparel/Liners): Utilize 30D–100D ripstop or nylon/cotton blends to ensure comfort, breathability, and flexibility while retaining resistance to tears.

Select the denier that solves your specific wear-and-tear challenge without over-engineering the weight of your final product.

Summary Table:

| Weight Class (Denier) | Common Constructions | Primary Applications |

|---|---|---|

| Ultra-Lightweight (30D-100D) | Nylon Ripstop | Lightweight Apparel, Gear Liners |

| Mid-Range (160D-420D) | Nylon Packcloth, Bottom Weights | Backpacks, Reinforcement Areas |

| Heavy-Duty (500D-1000D) | Textured Nylon/Polyester | General Gear, Industrial Bags |

| Ballistic (630D-1050D) | Ballistic Nylon | Extreme-Duty Luggage, Tactical Equipment |

Ready to Engineer with the Right CORDURA Fabric?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear and gear for distributors, brand owners, and bulk clients. Our expertise in material selection ensures your products are built with the optimal balance of durability, weight, and flexibility—whether you need ultra-lightweight ripstop for apparel or heavy-duty ballistic nylon for industrial applications.

Let's discuss your specific needs: Contact our material experts today to leverage our production capabilities and bring your high-performance products to life.

Visual Guide

Related Products

- Wholesale Leather Ankle Boots with Lug Soles for Custom Brand Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Wholesale Leather Safety Boots with Customizable Protective Toe

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What is the primary function of industrial roughing machines? Mastering Surface Preparation for Footwear Durability

- What is the central function of wearable health platforms? Unlocking Real-Time Data Insights for Better Care

- What materials are used in cowboy boot construction? A Guide to Leather, Soles & Heels

- How does styling influence the choice of winter boots? Finding the Perfect Balance for Your Lifestyle

- What are the features of a control shoe? Key Support for Severe Overpronation

- What are some good footwear habits to ensure safety and comfort? Master the Simple System for All-Day Comfort

- What materials are traditionally used for English riding boots? A Guide to Leather & Modern Alternatives

- What role do smart pressure-sensing insoles play in Parkinson's gait monitoring? Advanced Biometric Gait Analysis