In short, safety shoes are mandatory in any environment where feet are at risk of injury from impact, compression, punctures, chemicals, or electrical hazards. This includes obvious sectors like construction and manufacturing, but also extends to logistics, healthcare, and specialized electrical work, each with its own specific type of required protection.

The core principle isn't about a specific job title, but about the risks present in the environment. Understanding the specific hazard—be it a falling object, a sharp nail, or an electrical current—is the key to determining the need for and type of mandatory safety footwear.

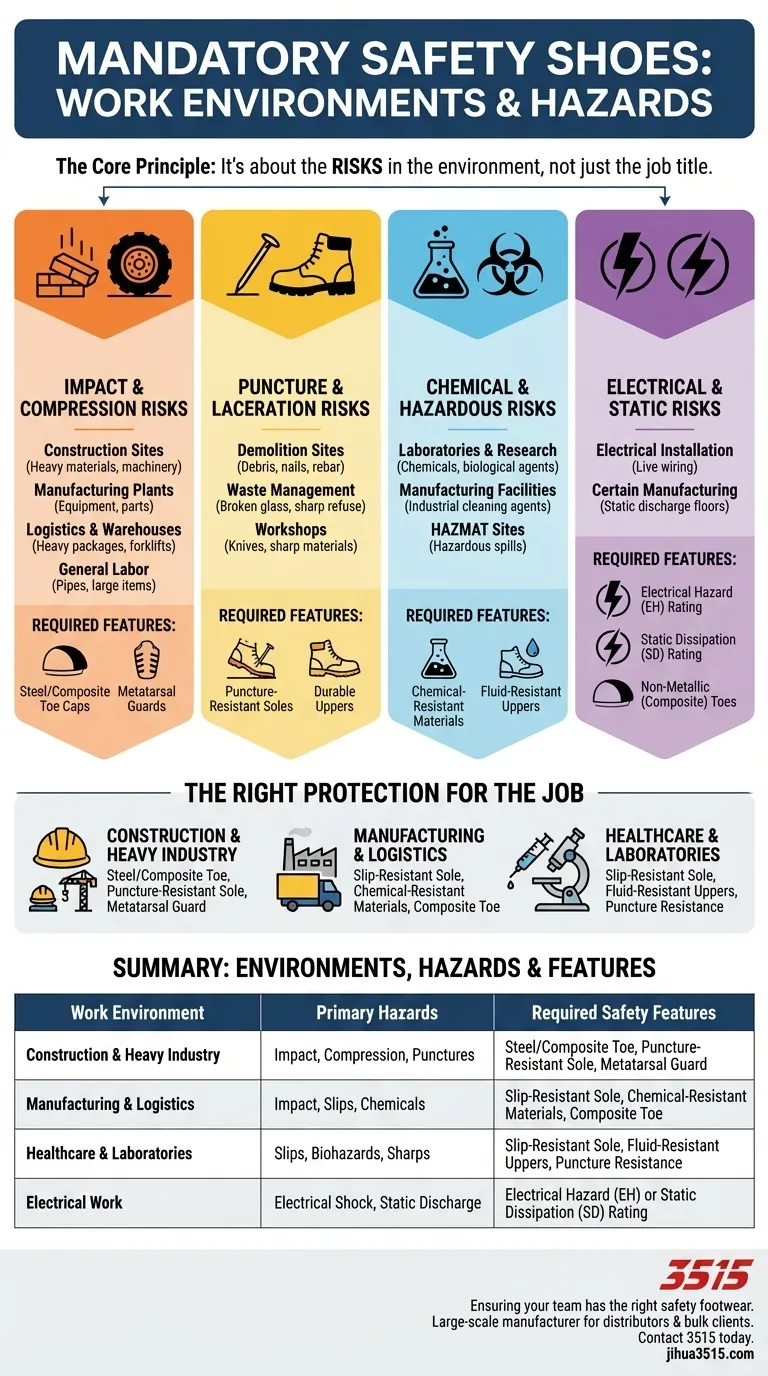

Identifying the Underlying Hazards

The requirement for safety shoes is directly tied to mitigating specific, foreseeable risks in the workplace. Different environments present different threats, which is why various types of safety footwear exist.

Impact and Compression Risks

This is the most common reason for mandatory safety footwear. These hazards come from the potential for objects to fall onto or roll over the feet.

Workplaces include:

- Construction sites: Handling heavy building materials, tools, and operating machinery.

- Manufacturing plants: Working around heavy equipment, parts, and production lines.

- Logistics and Warehouses: Moving heavy packages, operating forklifts, and stacking goods.

- General labor: Handling items like pipes, stones, tree trunks, or large wheels.

Puncture and Laceration Risks

Sharp objects on the ground or in use can easily penetrate standard footwear, causing severe injury.

Workplaces include:

- Demolition and construction sites: Debris fields with nails, scrap metal, and rebar.

- Waste management and recycling centers: Handling broken glass, scrap metal, and other sharp refuse.

- Workshops: Using tools like knives, axes, or handling sharp materials.

Chemical and Hazardous Material Risks

Exposure to corrosive or harmful substances requires footwear that can resist chemical breakdown and protect the skin.

Workplaces include:

- Laboratories and research facilities: Handling chemicals and biological agents.

- Manufacturing facilities: Using industrial cleaning agents, solvents, or other chemicals.

- HAZMAT response sites: Cleaning up spills of hazardous materials.

Electrical and Static Risks

Specialized footwear is crucial for protecting against electrical shock or preventing the buildup of static electricity, which could ignite flammable materials.

Workplaces include:

- Electrical installation and repair: Working with live or potentially live wiring.

- Certain manufacturing environments: Working on floors that can produce static discharge, especially around sensitive electronics or flammable vapors.

The Right Protection for the Right Job

Not all safety shoes are created equal. The specific features required are dictated entirely by the hazards of the environment, leading to different mandatory standards across industries.

For Construction and Heavy Industry

The primary needs are maximum protection against impact and punctures.

- Steel toe caps are essential for impact and compression resistance.

- Puncture-resistant soles prevent sharp objects from penetrating the foot.

- Metatarsal guards may be required for extra protection of the top of the foot.

For Manufacturing and Logistics

This environment often combines impact risk with other specific hazards.

- Slip-resistant soles are critical on potentially wet or oily floors.

- Chemical-resistant materials are necessary when working with corrosive substances.

- Composite toes (non-metallic) are often preferred for their lighter weight and because they don't conduct electricity.

For Healthcare and Laboratories

Protection here shifts from heavy impact to biohazards, sharps, and slips.

- Slip resistance is a top priority on smooth, frequently cleaned floors.

- Fluid-resistant and easy-to-clean uppers protect against spills of chemicals or bodily fluids.

- Puncture resistance is key to preventing injury from dropped needles or sharp instruments.

Making the Right Choice for Your Environment

Choosing the correct footwear isn't just about compliance; it's about effective safety. The decision should always be based on a thorough risk assessment of the specific tasks and workplace.

- If your primary focus is protection from heavy objects: Mandate footwear with certified steel or composite toe caps and consider metatarsal guards for high-risk areas.

- If your primary focus is preventing slips and falls: Require shoes with a high-traction, slip-resistant sole suitable for the specific floor surfaces in your facility.

- If your primary focus is electrical safety: Ensure employees use footwear specifically rated for electrical hazard (EH) protection or static dissipation (SD), depending on the need.

- If your primary focus is protection from sharp objects: The mandatory requirement must include puncture-resistant soles to guard against nails, glass, and metal shards.

Ultimately, the mandate for safety shoes is a direct response to the identifiable dangers present in a work environment.

Summary Table:

| Work Environment | Primary Hazards | Required Safety Features |

|---|---|---|

| Construction & Heavy Industry | Impact, Compression, Punctures | Steel/Composite Toe, Puncture-Resistant Sole, Metatarsal Guard |

| Manufacturing & Logistics | Impact, Slips, Chemicals | Slip-Resistant Sole, Chemical-Resistant Materials, Composite Toe |

| Healthcare & Laboratories | Slips, Biohazards, Sharps | Slip-Resistant Sole, Fluid-Resistant Uppers, Puncture Resistance |

| Electrical Work | Electrical Shock, Static Discharge | Electrical Hazard (EH) or Static Dissipation (SD) Rating |

Ensure your team has the right safety footwear for their specific hazards.

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, designed to meet the specific demands of construction, manufacturing, logistics, healthcare, and electrical work.

We help you protect your workforce, ensure compliance, and reduce workplace injuries.

Contact 3515 today for a consultation on your safety footwear needs.

Visual Guide

Related Products

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- How can spatial grouping analysis tools be used to optimize the production layout for safety shoes and tactical boots?

- What is the primary function of protective footwear in poultry biosecurity? Maximize Flock Health and Biosecurity

- What are the benefits of a waterproof lining in safety boots? Protect Your Feet and Your Gear

- What is the function of high-precision three-dimensional force plates in gait induction experiments for footwear safety?

- How does the ergonomic design of protective footwear reduce the risk of WMSD? Enhance Worker Safety and Comfort

- Why is a fuzzy logic model more effective for professional footwear assets? Modeling Gradual Wear with Precision

- How do safety shoes and PPE impact thermal comfort? Balance Protection with Thermal Regulation in Workshops

- What are the core functions of industrial-grade sewing equipment for safety shoes? Ensuring High-Tension Seam Integrity